Hornady Annealing Kit User Manual

Page 7

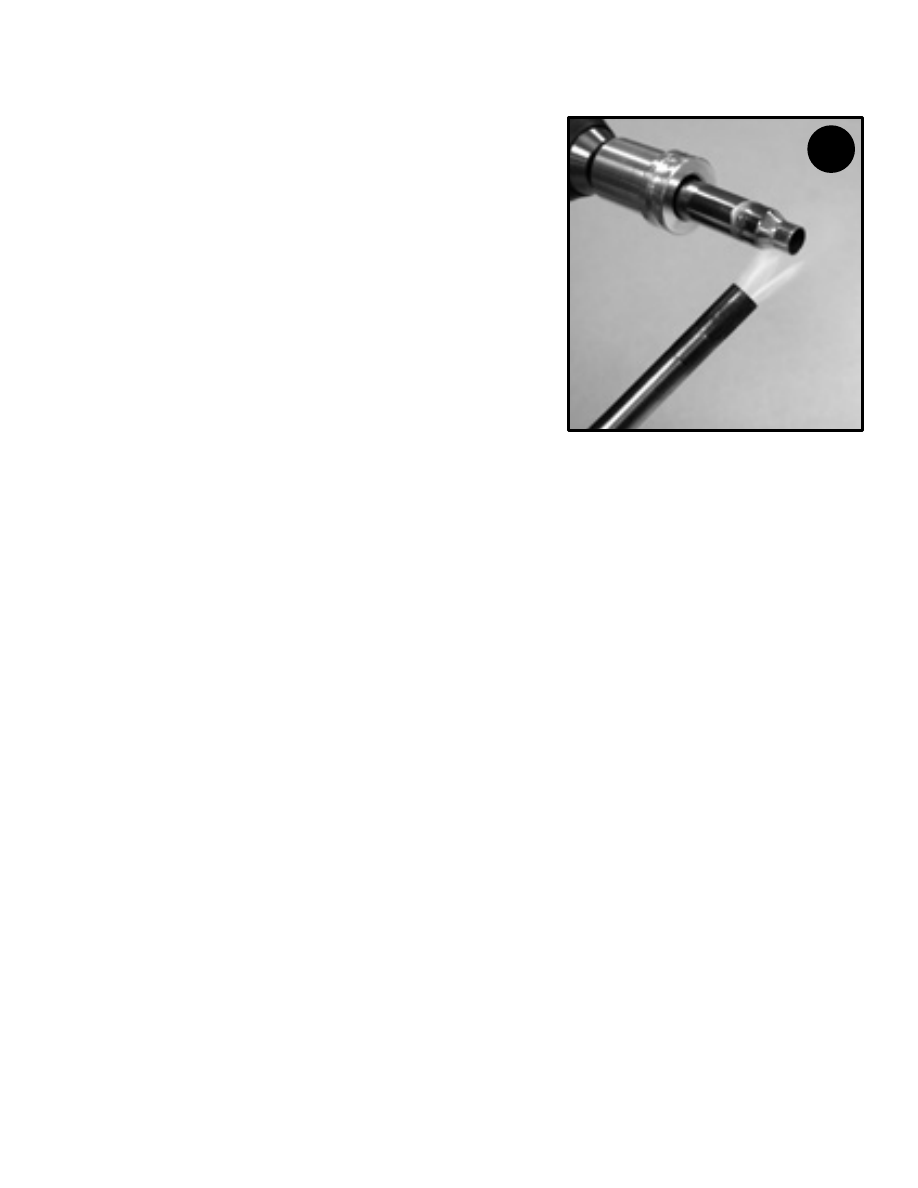

8. Insert marked, empty case in tool. Start power driver (if using a hand drill, it is

most convenient to lock the drill in the ON position).

9. Bring spinning case into flame. Locate

middle of case neck in center of flame,

near end of bright blue inner cone. Always

locate flame on neck area only. NEVER

APPLY FLAME DIRECTLY TO CASE BODY OR

MARKING MATERIAL. AVOID CENTERING

FLAME NEAR CASE SHOULDER.

(See photo B.)

10. As case spins and heats, observe condition

of temperature sensing material. When that material melts the case neck,

it has been sufficiently annealed. FURTHER ANNEALING ONLY SOFTENS

THE CASE SHOULDER WHICH CAN REDUCE ACCURACY AND CASE LIFE.

11. Immediately and quickly dump case into water by moving and inverting power

driver so that case falls out of Hornady tool and into water container. (Avoid

tipping the torch and avoid getting the power cord near the flame or hot torch

tip.) RAPID COOLING DOES NOT IMPROVE ANNEALING. IT IS NEEDED TO

PREVENT ANNEALING HEAT FROM MIGRATING TO THE CASE HEAD. NEVER

USE ANY CASE WHERE CASE HEAD ANNEALING MIGHT HAVE OCCURRED.

12. Insert another case in Hornady tool and repeat process. For maximum uniformity,

continue until all cases in that batch are annealed.

13. It is worthwhile to tumble all cases after annealing. This dries and

removes heat-generated scale and further cleans cases.

B