Annealing process – Hornady Annealing Kit User Manual

Page 6

ANNEALING PROCESS

1. Clean excessive debris from empty cases using a vibratory tumbler and

cleaning media (Hornday offers these tools). Clean cases are easier

to inspect and they heat more consistently and show change in the

temperature sensing material more clearly.

2. Visually inspect all cases. Verify that no case contains any of the following:

Primer cup, powder, debris of any kind, obvious defects, split neck, excessive

thinning near web-to-body juncture.

3. Use propane torch fitted with medium sized tip, on suitable work area flat,

stable, and free of flammable materials or air currents. (Clamping the

propane bottle loosely into a bench vise prevents the torch from tipping

over.)

4. Position a large can that is about 1/2 full of water near the torch so it is

convenient to dump annealed cases from tool into water.

5. Install Hornady Case Neck Annealing Tool in electric screw driver or drill.

If you are using a drill, securely tighten the chuck and adjust the speed

to about 200 RPMs, which is near the slowest adjustment speed of most

drills.

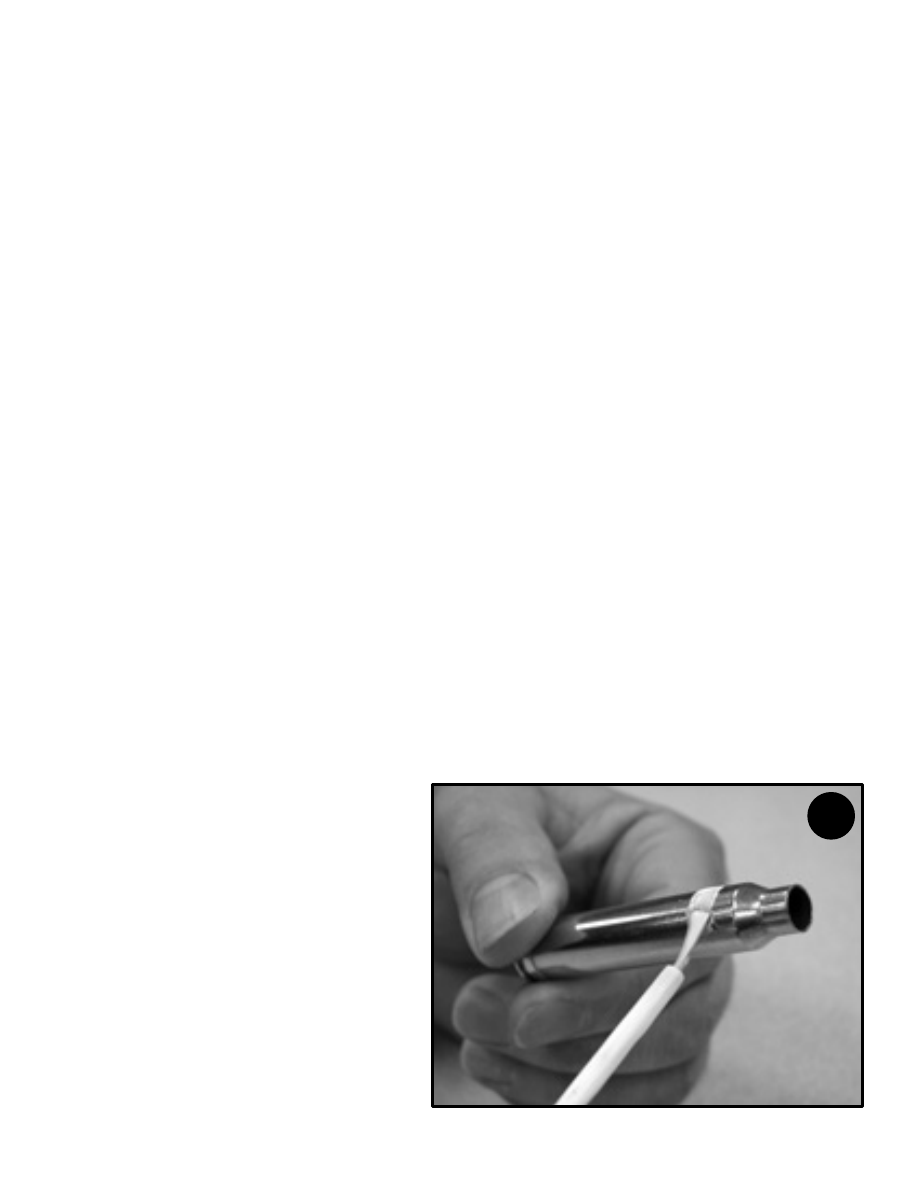

6. Apply the temperature

indicating paste to case body

at a point about 1/4” below

case shoulder, and mark all

cases. (See photo A.)

7. Light torch, adjust valve to

produce a visible medium

length blue flame and rotate

torch so that flame is pointed

in a convenient direction.

A