Defi Racer Gauge 80 tachometer User Manual

Manual, Safety warning 【please read carefully, Lineup

Before handling (for installation personnel)

Properties for safety warning

Indicates attention needs to be paid. (Including warnings)

Indicates restricted actions. (PROHIBITED actions)

Indicates actions that need to be carried out. (MUST actions)

Prohibited

Must

Thank you very much for purchasing our product.

This product is an additional product for providing information to automobile users about engine conditions

and other important factors. Before installing and using the product, please read this manual and the

warranty card thoroughly. All sections are for customers and installation personnels. After installation,

please keep this manual and the warranty card for future reference. In the event that this product (or the

vehicle in which it is installed) is lent to or transferred to another person, please be sure this operation

manual and warranty card accompany the product.

Defi will not be held responsible for accidents or damages related to installation of this product.

When installing and operating this product, be sure to read the cautionary items in the operation manual for

the vehicle in which this product will be installed in addition to the manual of this product. Please obtain a

full understanding of the cautionary items and use the product accordingly. Before using the product,

please confirm all the components are included in the package.

Safety Warning

【Please read carefully.】

In this manual, the degree of hazard arising from actions such as improper operation is separated into the 3

levels "Danger," "Warning," and "Caution." In addition, instructions that must be followed for safe and

proper use of this product as well as practices that must be maintained are marked with a "Confirmation"

heading. Please read and become familiar with these sections.

Caution

Warning

Confirmation

Danger

Indicates the imminent dangerous situation of death or serious injury if the product is

mishandled.

Indicates the possibility of death or serious injury if the product is mishandled.

Indicates a conceivable source of personal injury or damage to equipment if the product

is improperly operated.

Indicates an instruction that must be performed or practice that must be maintained.

Warning

disassemble/

modify

Caution

24V

Carefully consider the installation location and driver's operation of the product before installation. Do

not install the product where it interrupts driving and the safety deices of vehicle such as the airbag

system. Be sure not to install the unit where it could fall. Improper installation or operation could

cause the product to fall and damage the vehicle or cause serious danger by impeding driving.

Do not disassemble or modify this product. Such actions will not only void the warranty but also

damage or destroy the product.

Do not perform installation of this product immediately after the engine has been switched off. The

engine and exhaust system are extremely hot at this time and can cause burns if touched.

Ensure that the wiring of this product does not have an adverse impact on the other wiring of the vehicle. Any

controlling devices or other electronic components of the vehicle could be damaged.

Discontinue use of this product if the product doesn't operate or operates improperly. Continued use while the

condition exists could result in an accident or fire.

Please keep children and infants away from the installation area. Children may swallow small parts or be injured in

other ways.

Do not install this product in the area where safety equipment such as airbags are mounted. This may cause more

injuries in the event of an accident.

Danger

Ensure that the vehicle will remain stationary and turn off the engine before installing this product. Failure to do so

could result in a fire, and could make the vehicle move during installation.

Remove the key from the ignition and disconnect the negative (-) battery terminal prior to installation of this product.

Failure to do so could result in a fire caused by an electrical short circuit.

Take care not to install this product in a way that interferes with safety equipment such as seat belts and air bag

systems or vehicle operation equipment such as engine controls, steering wheel or brake systems. Interference

with normal operation of the vehicle can result in an accident or fire.

Solder or use a solderless connector for wiring connections and make sure connections are insulated. In areas

where there could be tension or sudden impacts on the wiring, safeguard the wiring with corrugated tubing or other

shock absorbent material. Accidental shorts can cause fires.

When wiring power supply wire, to avoid the risk of electrical shock or fire, be sure to confirm that there is no

disconnection or breakage of wire. Poor connection can result in short-circuit, electrical shock, fire, or other hazards.

The ignition-switched +12V(IGN) line must be connected to the vehicle's ignition-switched wire with a fuse of 30A or

less. High-capacity fuse(more than 30A) will not blowout even with an abnormal current flow and may cause fire.

Use the fuse of regulated capacity when the fuse of the power wire is changed. Using a fuse that exceeds regulated

capacity may cause fire and may affect the accuracy.

Do not install the product at the wet places. It may result in a fire caused by an electrical short circuit.

This product is designed for use on 12V vehicles. Do not install this product on vehicles with 24V systems.

Insulate any unused wires. If any wires or connectors loosen during installation, please make sure

they are correctly reattached.

Do not drop any of the components of this product. It may result in damage to the product.

Do not apply excessive force on switches/terminals. It may result in damage to the product.

Do not use wires other than the provided wires.

Do not attach wires on the body of the vehicle or engine parts as this may result in damage to the product.

Install wires away from ignition and also radio signal frequency interference as this could cause the gauges to

malfunction.

Do not place wires near the engine, exhaust pipe or turbine. It may result in damage or fusion of wires.

Make sure the waterproof processing is done when diverging wires in the engine compartment.

Wear gloves to avoid burns when soldering and cuts when installing wires, sharp edges of parts.

When using sunshade, put sunshade between products and windshield to avoid direct sun exposure .

Use the dried soft cloth for cleanup. Do not use the cleaner except for the neutral detergent. It result in the trouble.

Do not pull the wires out of connectors forcefully. The connectors may be broken and the wires

may be cut. When pulling out the wires, press the lock firmly and unclip the locks of connectors.

Do not install gauges into the passenger side or center of the dashboard. It doesn't meet

vehicle safety standards.

http://www.defi-shop.com/

'11.10-1

Confirmation

Be sure to follow all instructions in this manual to ensure safe installation and operation of the product.

When the negative (-) battery terminal is disconnected, equipment such as clocks and audio components having

internal memory may lose their memory data. Follow the operation manual of each component to reset data after

installation of this product.

After installation is complete, return this operation manual, warranty card, and the package to the customer along

with the warranty.

The gauge pointer may not be in the proper position when you purchase the product. Normal function will resume

when power is connected.

Please confirm with the maintenance book on the car that the manufacturer issued when installing and detaching

genuine parts.

Before tapping wires, check the voltage of the existing wire. After tapping the wire, check the voltage of the tapped

wire again to confirm whether you have tapped into the proper place.

If car navigation system or car television is installed in vehicle, gauges and wires of this product need to be kept as

far away as possible from the wiring and installing positions of car navigation system or car television. Failure to do

so may result in interference of television display.

On no event will Nippon Seiki Co., Ltd. be liable to you for any damages or losses of genuine parts for your vehicle

while installing.

Confirmation

About Installation and Operation(for customer and installation personnel)

Warning

On no event will Nippon Seiki Co., Ltd. be liable to you for any damages arising out of the use or inability to use the

product, even if Nippon Seiki Co., Ltd. has been advised of the possibility of such damage.

Do not pull the wires out of connectors forcefully. The connectors may be broken and

the wires may be cut. When pulling out the wires, press the lock firmly and unclip the

locks of connectors.

Caution

This product cannot be linked to either the ADVANCE System or the Defi-Link System.

The information displayed on this product are for reference purposes only. Please drive according to the indication

of vehicle's originally equipped instruments.

This product uses high luminance LEDs. When several gauges are lined up, there might be color difference in the

LED production tolerance, but it is not malfunction.

This product can be used only on 1, 2, 3, 4, 5, 6, and 8 cylinder vehicles with 4 cycle engine. Refer to the Product

Specifications. Engine revolution signal of diesel vehicles cannot be displayed.

Please check the installed product regularly. Durability might deteriorate according to use conditions, etc.

Please have this product installed by the retail store or dealer where it was purchased. Installation by the customer

will void the warranty.

Do not disassemble or modify this product. Such actions will not only void the warranty but also damage or destroy the product.

In order to ensure safe driving, check the information on the gauge only for short periods of time. Looking at the

display for long periods of time could distract adequate attention from the road and result in an accident.

Discontinue use of this product if the gauge doesn't operate, water gets into the unit, or smoke or a strange odor

comes from the unit. If such a condition occurs, contact the sales outlet or installation personnel as soon as

possible. Continued use while the condition exists could result in an accident or fire.

Do not operate during driving.

Fix the switch unit and other parts tightly to the vehicle to avoid that children swallow those.

Manual

Racer Gauge Tachometer Φ80

DF12001∼DF12003, DF12101∼DF12103

DF12001

DF12101

DF12002

DF12102

DF12003

DF12103

Display range

0

∼9000RPM

0

∼11000RPM

Blue

Illumination color of gauge and switch

Red

White

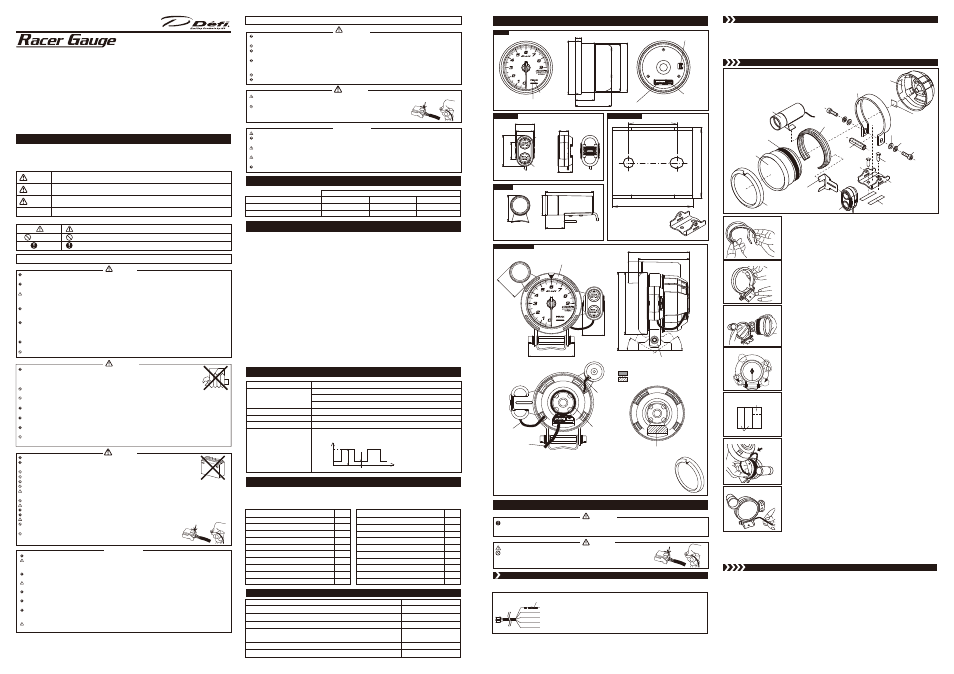

STEP3

Installing gauge

STEP3

Installing gauge

Install the gauge as shown in the following procedures and figures.

①Gauge

⑰Buffer

②Switch unit

③Regular Position Bezel

④Back case

⑱Double sided tape

⑤Mounting band

⑥Mounting rubber

⑧Indicator

⑪Mounting bracket

⑫Attachment

for switch unit

⑬M6 bolt

⑭Spring lock washer

⑮Washer

⑯Spacer

⑲Tapping screw

⑱Double sided tape

【Figure1】 Gauge assembly

1) Attach the buffer around the gauge.

【Figure1】

※Do not touch on the front face of the gauge so as not to put fingerprints.

2) Fit the mounting rubber inside of the mounting band.

【Figure2】

3) Fix the mounting band to the mounting bracket temporarily with the spacer, bolts,

washers, and spring lock washers. Tighten bolts loosely by hands. Do not use a

hexagonal wrench (Allen key) at this stage.

【Figure3】

4) Insert the switch unit into the attachment for switch unit.

【Figure1】

※If the switch unit is fixed to another place other than the gauge, do not use the

attachment for switch unit.

5) Fit the attachment for switch unit and indicator into the mounting band. And then fit

the gauge into the mounting band. Locate the switch unit and the indicator roughly

at this stage. The switch unit and the indicator can be positioned in the range which

they do not touch the mounting bracket and bolts.

【Figure4】

【Figure5】

※Do not take hands off from the gauge so as the gauge does not fall down.

※If the switch unit is fixed to another place other than the gauge, do not fix/use the

attachment for switch unit to the mounting band.

6) Identify the position of the mounting bracket with the gauge fitted into the mounting

band. Mark the shape of the mounting bracket and the position of the screw holes.

The figure printed on the package can be used to position the screw holes.

※To check that there is enough space for installation, identify the gauge position

with the gauge, switch unit, and indicator fitted into the mounting band.

※When setting the gauge angle, take care not to scratch by hitting the gauge to the

mounting bracket.

7) Disassemble the mounting band from the mounting bracket, and disassemble the

gauge, attachment for switch unit, and indicator from the mounting band.

8) Attach double sided tapes on the bottom of the mounting bracket.

【Figure1】

【Figure6】

9) Fix the mounting bracket on the gauge installing position by using the tapping screws.

10) Fit the attachment for switch unit, indicator, and gauge into the mounting band again.

Take notice that the angle of the switch unit and the indicator cannot be changed

while the bolts are fastened.

※If the switch unit is fixed to another place other than the gauge, do not fix/use the

attachment for switch unit to the mounting band.

11) Attach the double sided tape on the back side of the gauge.

【Figure1】

【Figure6】

12) Pass the indicator wire and switch unit wire through the holes of the back case from

the outside. Connect the indicator wire to the connector on the gauge. Refer to part

names section.

【Figure7】

【Assembling example】

13) Put the back case on the gauge. Position the hole for the power supply & tachometer

signal wire to the gauge connector for it. Refer to part names section. The indicator

wire can be stored in the back space in the back case.

【Assembling example】

14) Connect the switch unit wire to the connector on the back side of the gauge. The

indicator wire can be stored in the storage space in the back case neatly.

【Assembling example】

15) Connect the power supply & tachometer signal wire to the connector on the back

side of the gauge.

【Assembling example】

16) Fit the mounting band with the gauge in the mounting bracket by using a spacer,

bolts, washer, and spring lock washer.

※Depending on the installing space, it may difficult to fit the gauge. Do not pull

wires forcefully and take notice not to hit the vehicle by parts.

17) Fasten the bolts with a hexagonal wrench (Allen key) firmly.

【Figure8】

18) Fit the regular position bezel onto the gauge with setting the ▼ mark at the position

you like.

【Figure2】Fitting rubber in band

【Figure3】Fixing band to bracket

【Figure5】Range of fitting of switch unit

and indicator

【Figure6】How to use double sided tape

【Figure4】Fitting indicator, attachment

for switch unit, and gauge in band

【Figure8】Fasten bolts with hexagonal

wrench

【Figure7】Connect indicator wire

For bottom of bracket

For inner side of back case

Pass wires

through

holes from

back side

STEP4

Final check and setup

STEP4

Final check and setup

1) Make sure the gauge is fixed on the installing position firmly. Then turn the vehicle engine on and off and check the

movement of the pointer, illumination of the gauge, and engine speed signal input.

※Make sure there are no tools on the vehicle floor and that the vehicle surrounding is safe before turning on the engine.

2) Go on to the operation section and set up the number of cylinders, and so on. Give this manual to the customer if

he/she sets up by himself/herself.

front

front

back

back

Dimensions in mm(inches) and part names

Main Features

(for customer)

Lineup

(for customer)

●Stepping motor "STS26A"

Maximum angle of deflective 270° (full sweep) is controlled by the microcomputer up to 4600 division(0.057° each) to

provide high precision in the accuracy of information generated.

The stepping motor is sufficient for quick response of all sorts of professional motorsports.

●LED illumination

The gauge dial is invisible while the ignition switch is off. Once the ignition switch is turned on, a clear display appears

by colored LED illumination.

The gauge dial illumination and the red emitting needle pointer provide high visibility.

●Opening and closing modes

The gauge dial and the needle pointer performs opening and closing modes interlocked with turning ON/OFF of the ignition.

●Adjustable brightness

There are 5 stages of brightness for the daytime and 6 stages for the nighttime. The brightness can be

decreased/increased with the vehicle lights switched on/off.

●Dual warnings of light and buzzer

Two customer-defined warning RPMs can be set. When the RPMs are exceeded, the warning LED blinks/lights up

and the warning buzzer sounds.

●Exclusive large-sized indicator

The exclusive large-sized indicator which lights in green and red enhances the visibility of warnings in addition to the

warning LED in the gauge.

●Peak memory function

The maximum RPM during driving can be stored and checked later.

●Detachable switch unit

The large-sized switch unit with light is fixable on the gauge and is also detachable.

●Exclusive mounting band and back case

The gauge is clinched by using the exclusive mounting band and back case. Wires can be stored in the back case neatly.

Product Specifications(for customer and installation personnel)

Power Supply Voltage

Current Consumption

Operational Temperature Range

Storage Temperature Range

Applicable Number of Cylinders

Applicable Engine Speed Pulse

DC10V to 15V

(For 12V vehicles)

+B (red) line

IGN (orange) line

ILM (white) line

−20 to +60℃, −4 to +140°F (under 80% relative humidity)

−30 to +80℃, −22 to +176°F (under 80% relative humidity)

1

・2・3・4・5・6・8

The wave form of the engine speed signal should meet the requirements

of the following graph.

MAX 0.4A

(Dark current 0mA)

MAX 0.4A

MAX 2mA

Engine speed input (blue wire)

V1) 4.0V and above

V2) 0

∼1.5V

Time

V1

V2

Volt

4.0V and

above

0

∼1.5V

Part Name

Quantity

①Gauge

②Switch unit(wire 45cm, 1.48ft)

③Regular Position Bezel

④Back case

⑤Mounting band

⑥Mounting rubber

⑦Power supply & tachometer signal wire 2.2m, 7.2ft

⑧Indicator(wire 20cm, 7.8in)

⑨Operation manual

⑩Warranty card

1

1

1

1

1

1

1

1

1

1

Part Name

Quantity

1

1

2

2

2

1

1

1

2

5

⑪Mounting bracket

⑫Attachment for switch unit

⑬M6 bolt

⑭Spring lock washer

⑮Washer

⑯Spacer

⑰Buffer

⑱Double sided tape

⑲Tapping screw

⑳Solderless connector

Part Name

Φ80(3 1/8") Mounting band set

(Mounting band x1, Mounting rubber x1)

Part Number

PDF07103G

Φ80(3 1/8") Back case set

(Back case x1, Buffer x1)

PDF07101G

Power supply & tachometer signal wire

PDF12010H

Φ80(3 1/8") Mounting bracket set

(Mounting bracket x1、M6 bolt x2,

Spring lock washer x2, Washer x2, Spacer x1, Tapping screw x2

)

PDF07104G

Φ80(3 1/8") Regular Position Bezel

PDF07105G

Fuse for Power supply wire(1A) 2pcs

PDF07113G

The following parts are included with this product. Confirm that all parts are present before installing the product. In

addition, these parts are sold separately for part replacement. Contact your retailer for further information.

NOTE: Japanese operation manual and wiring manual are included other than the parts listed below. They are effective

only in Japan.

Parts List

(for customer and installation personnel)

Installation

(for customer and installation personnel)

Optional Parts(for customer)

Gauge

Gauge

Connector for indicator

Connector for switch unit

Connector for power supply & tachometer signal wire

φ80(3.15")

30.1(1.19")

9.9(0.39")

58(2.29")

φ76.6(3.02")

φ86.8(3.42")

Switch Unit

Switch Unit

▼switch

▲switch

31.4(1.24")

50.6(1.99")

26.7(1.05")

27(1.06")

15.7(0.62")

23.7(0.93")

Mounting Bracket

Mounting Bracket

30(1.18")

50(1.97")

44(1.73")

Indicator

Indicator

78(3.07")

29.7(1.18")

φ32.2(1.27")

41.6(1.64")

The indicator is exclusive to

Φ80mm tachometer.

Wire 45cm(1.48ft)

Wire 20cm(7.8")

This figure is printed on the

package at full scale. Cut and

use it to locate the mounting

bracket and position the screws.

▼Regular Position Bezel

69.2(2.72")

Assembling example

Assembling example

Holes for indicator wire or switch unit wire

A hole for power supply & tachometer

signal wire

A hole for power supply & tachometer signal wire

36.9(1.45")

34.2(1.35")

92.1(3.63")

30

°

35

°

76.5(3.01")

116(4.55")

φ91.8(3.61")

The mounting band is movable 4mm up and down.

▼Regular Position Bezel

Regular Position Bezel is a ring to fit onto the gauge front. The ▼ mark can be used as an indicator

of warning or shift-up in addition to the warning LED and the external indicator. By setting the ▼

mark at idling engine speed, you can notice the slight difference of your vehicle.

Regular Position Bezel is removable from the gauge. To change the position of the ▼ mark, remove

it once and then attach it again.

Storage space for

switch unit wire

Indicator wire

power supply &

tachometer

signal wire

Switch

unit wire

STEP

1 Wiring power supply & tachometer signal wire

STEP

1 Wiring power supply & tachometer signal wire

STEP2

Wiring check

STEP2

Wiring check

1) Connect the power supply & tachometer signal wire to the back side of the gauge.

2) Turn the key in the ignition. Then check the gauge illumination is lighted and the gauge pointer moves.

3) Turn on the vehicle lights and make sure the gauge illumination is dimmed.

4) Turn the ignition key off. Then check the gauge pointer points back to the zero point and the gauge illumination is

turned off.

5) To fix the gauge on a vehicle in the next step, disconnect the power supply & tachometer signal wire.

3) Reconnect negative (

−) battery cable of the vehicle.

1) Disconnect negative (

−) battery cable of the vehicle.

2) Wire the power supply & tachometer signal wire as shown in the following figure.

Power supply & tachometer signal wire

(2.2m, 7.2ft)

Red

: Battery(To 12V battery wire)

White

: +ILM (To 12V wire when small light is on)

Orange

: IGN (To 12V wire when ignition is on)

Black

: GND (To ground, negative battery terminal)

Blue

: Engine speed input

Fuse 1A

Carefully read the "Before Installation" and "About Installation and Operation" sections of the manual concerning

installation and operation. Then install the product properly and safely. Installation in an unsuitable location or

improper installation can result in the product falling from its position or damage to the vehicle.

Warning

Take care not to scratch the gauge or vehicle by hitting or glinding the parts.

Do not pull the wires out of connectors forcefully. The connectors may be broken and

the wires may be cut. When pulling out the wires, press the lock firmly and unclip the

locks of connectors.

Caution

Warning LED(Red)

PEAK LED(Blue)