Defi ADVANCE BF (except tachometer) User Manual

Page 2

→

↑

→

(provided with commercial parts)

(provided with

commercial parts)

OIL PRESS.

(DF081, 089, 102 series)

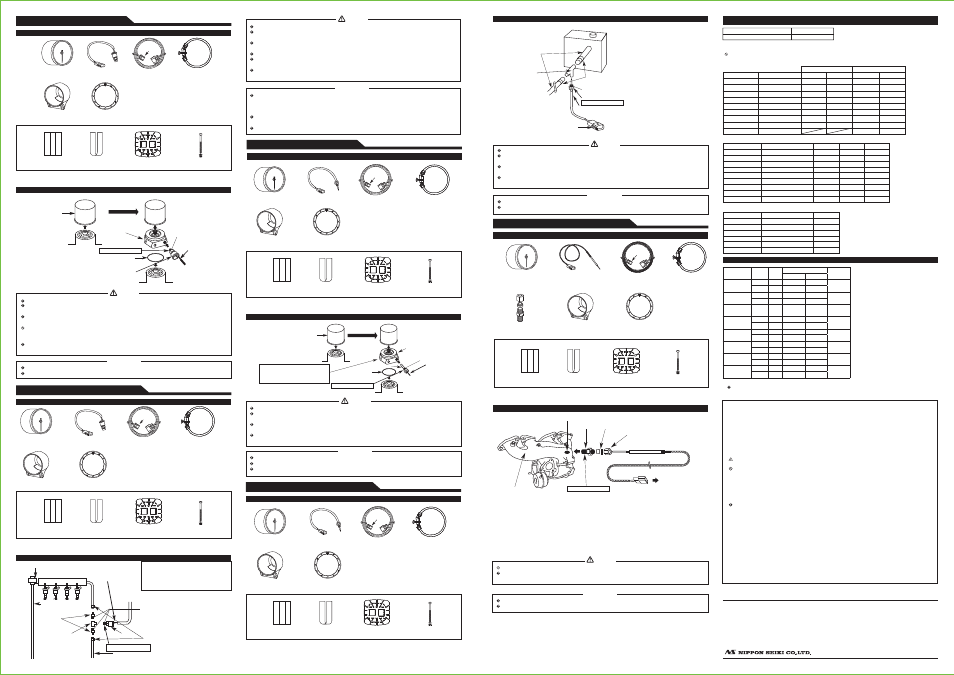

■Components

Sensor wire 3m

(10ft) 1pc

Meter wire 0.25m

(10”) 1pc

Gauge 1pc

Pressure sensor

(1/8PT) 1pc

Meter cup 1pc

*Regular position

bezel 1pc(CR only)

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

*A regular position bezel is not included in ADVANCE BF gauge unit. (Sold separately: PDF08607G)

Black

3pins

■How to attach pressure sensor (Use a commercial sensor attachment.)

Engine

Engine

Sensor attachment

(commercially available)

O ring

Sensor

To sensor wire

Thread size 1/8PT

Detach the original

element.

Wind Teflon tape.

Be sure not to twist.

The thread size of the pressure sensor is 1/8PT. Use a sensor attachment of 1/8PT.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Oil spills by the installation work. Please replenish the engine with oil. The engine might overheat

when oil is too little.

To avoid oil leaks by installing of the sensors, use Teflon tape. Before driving, inspect oil blocks for

leaks. Leaks could cause a fire or damage the engine.

Do not install the sensor near oil pump. Do not install the sensor to pressure switch directly. Failure to

do so could damage the sensor because the pressure pulsation is too big and exceed three times

full-scale momentarily.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

Warning

Confirmation

FUEL PRESS.

(DF082, 090, 103 series)

■Components

Sensor wire 2.5m

(8 1/5ft) 1pc

Meter wire 0.25m

(10”) 1pc

Gauge 1pc

Pressure sensor

(1/8PT) 1pc

Meter cup 1pc

*Regular position

bezel 1pc(CR only)

Red

3pins

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

*A regular position bezel is not included in ADVANCE BF gauge unit. (Sold separately: PDF08607G)

Mounting bracket set

Double sided

tape 1pc

Buffer

1pc

Mounting

bracket 1pc

M4 bolt, nut,

washer 1pc

■How to attach pressure sensor (Use a commercial three-way joint and hose unions.)

Fuel pressure regulator

Three-way joint

(commercially available)

Fuel return pipe

(low pressure)

Hose union

(commercially

available)

Fuel feed pipe (high pressure)

Fix tightly with clamps.

(commercially available)

Wind Teflon tape.

Sensor

To sensor wire

Thread size 1/8PT

Be sure not to twist.

*Cut the fuel feed pipe and install hose

unions.

*If the material used for the inner surface

of fuel feed pipe is resin, a hose union

may not be fixed. Check the material

before cutting the fuel feed pipe.

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Before cutting the fuel feed pipe, be certain to remove the gas cap to relieve any pressure built up in the

fuel tank.

When cutting the fuel feed pipe, be certain to discharge static electricity. Otherwise, there is a possibility

of the ignition in gasoline.

Wear glasses to protect eyes when cutting the fuel filter pipe.

To avoid fuel leaks during installation of the sensor, use Teflon tape. Attach hose connection and fuel

feed tubing with clamps. Inspect pipes and hose connections for leaks before driving.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

The sensor must be installed on the feed (high pressure) pipe side between the fuel tank and the

fuel pressure regulator.

*It is not possible to obtain accurate fuel pressure from the return (low pressure) side at the rear of the

fuel pressure regulator.

The thread size of hose unions and the three-way joint need to be 1/8PT. Use hose unions and a

three-way joint of 1/8PT.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

Warning

Confirmation

OIL TEMP.

(DF083, 091, 104 series)

■Components

Gauge 1pc

Temperature sensor

(1/8PT) 1pc

Sensor wire 3m

(10ft) 1pc

Red

2pins

Meter wire 0.25m

(10”) 1pc

Meter cup 1pc

*Regular position

bezel 1pc(CR only)

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

*A regular position bezel is not included in ADVANCE BF gauge unit. (Sold separately: PDF08607G)

Mounting bracket set

Double sided

tape 1pc

Buffer

1pc

Mounting

bracket 1pc

M4 bolt, nut,

washer 1pc

Engine

Sensor attachment

(commercially available)

O ring

Sensor

Detach the original element.

Wind Teflon tape.

Be sure not to twist.

■How to attach temperature sensor (Use a commercial sensor attachment.)

Do not put the sensor in the side

hole. The depth of the hole for the

sensor must be more than 30mm.

Thread size 1/8PT

Engine

To sensor wire

The thread size of the temperature sensor is 1/8PT. Use a sensor attachment of 1/8PT.

The depth of the hole for the sensor must be more than 30mm.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Oil spills by the installation work. Please replenish the engine with oil. The engine might overheat

when oil is too little.

To avoid oil leaks by installing of the sensors, use Teflon tape. Before driving, inspect oil blocks for

leaks. Leaks could cause a fire or damage the engine.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

Warning

Confirmation

WATER TEMP.

(DF084, 092, 105 series)

■Components

Gauge 1pc

Temperature sensor

(1/8PT) 1pc

Sensor wire 3m

(10ft) 1pc

Pink

2pins

Meter cup 1pc

*Regular position

bezel 1pc(CR only)

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

*A regular position bezel is not included in ADVANCE BF gauge unit. (Sold separately: PDF08607G)

Mounting bracket set

Double sided

tape 1pc

Buffer

1pc

Mounting

bracket 1pc

M4 bolt, nut,

washer 1pc

Meter wire 0.25m

(10”) 1pc

Radiator

Attach tightly with clamps.

(commercially available)

Wind Teflon tape.

Sensor

→To sensor wire

Thread size 1/8PT

Be sure not to twist.

*Cut the upper hose and connect the

sensor attachment between hoses.

Upper hose

Sensor attachment

(commercially available)

Be sure the sensor wire is not twisted when installing the sensor. The sensor wire will be cut.

Coolant spills by the installation work. Please replenish the engine with coolant and bleed the air

from the system, or the engine might overheat.

To avoid water leaks during installation of the sensors, use Teflon tape. Attach the sensor

attachment and upper hose with clamps. Inspect hose connections for leaks before driving.

To avoid the damage of the sensor wire, please fix the waterproof connector on the vehicle body and

do not bend the sensor wire near the sensor.

The thread size of the temperature sensor is 1/8PT. Use a sensor attachment of 1/8PT.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

Confirmation

Warning

■How to attach temperature sensor (Use a commercial sensor attachment.)

■Components

Gauge 1pc

Exhaust temperature

sensor 1pc

Sensor wire 2.5m

(8 1/5ft) 1pc

Fitting (1/8PT) 1pc

Black

2pins

EXHAUST TEMP.

(DF085, 093, 106 series)

Meter wire 0.25m

(10”) 1pc

Meter cup 1pc

*Regular position

bezel 1pc(CR only)

Operation manual (this sheet) and warranty card are included other than the parts listed above. Keep them at hand.

*A regular position bezel is not included in ADVANCE BF gauge unit. (Sold separately: PDF08607G)

Mounting bracket set

Double sided

tape 1pc

Buffer

1pc

Mounting

bracket 1pc

M4 bolt, nut,

washer 1pc

Thread size 1/8PT

Exhaust manifold

Make a threaded screw

hole (1/8PT).

Sensor wire

Fitting(b)

Bushing

Exhaust temperature sensor

Fitting(a)

The thread size of the fitting is 1/8PT. Make a threaded screw hole of 1/8PT.

Tighten the sensor into the sensor attachment and then connect it to the sensor wire.

Confirmation

To avoid personal injury, do not install the exhaust temperature sensor while the engine is hot.

When making a hole, make sure no chip remains in the exhaust pipe or turbine. It may result in

damage to the engine, exhaust pipe, or turbine.

Warning

1) Make a 1/8PT threaded screw hole in the exhaust manifold pipe. (Weld if the pipe wall thickness is not

enough)

2) Dismantle the fitting. Do not crush the bushing inside the fitting.

3) Tighten the fitting(a) to the hole of the exhaust manifold.

4) Pierce the sensor through the fitting(b) and the busing.

5) Insert the edge of the sensor into the fitting(a) and position it at the center of the exhaust pipe.

6) Tighten the fitting(b).

■How to attach exhaust temperature sensor for exhaust temperature

Please refer to the Defi-Link ADVANCE Control unit operation manual for installation,

operation, troubleshooting, repair parts, optional parts, and terms and conditions.

Defi-Link Meter ADVANCE CR & ADVANCE BF Operation Manual

■

Issue First edition: August, 2013

■

Manufacturer Nippon Seiki Co., Ltd.

■

Contact Information Defi, Nippon Seiki Co., Ltd.

[Address] 190-1 Fujihashi 1-chome, Nagaoka-shi, Niigata 940-2141 JAPAN

[URL] http://www.defi-shop.com/

PAT. 3019067 PAT. 3019939

Mounting bracket set

Double sided

tape 1pc

Buffer

1pc

Mounting

bracket 1pc

M4 bolt, nut,

washer 1pc

Gauge

Default

setting

Unit

Setting range

Lighting

condition

Minimum Maximum

Turbo

100

kPa

-100

200

Set value

and above

14.5

PSI

-14.5

29

In-Mani Press

10

kPa

-100

200

Set value

and above

1.45

PSI

-14.5

29

Tachometer

7000

RPM

300

11000

Set value

and above

Oil press

120

kPa

0

1000

Set value

and below

17.5

PSI

0

145

Fuel press

150

kPa

0

600

Set value

and below

21.8

PSI

0

87

Oil temp

125

℃

0

150

Set value

and above

257

°

F

32

302

Water temp

105

℃

0

150

Set value

and above

221

°

F

32

302

Exhaust temp

850

℃

0

1100

Set value

and above

1562

°

F

32

2010

Maintenance & Check/Warranty & Servicing

■Warranty card・Terms and conditions

This product is delivered with this operation manual and a warranty card. Please read terms and conditions in this

manual thoroughly and keep the warranty card in a safe place. Failure to show this warranty will void the warranty.

■Warranty period

Limited one year warranty. The warranty period starts at the date of retail purchase by the original end-user

purchase. Please confirm the warranty card is provided with the information of retail store where purchased. Please

refer to Limited Warranty for details.

■Inspection

Please ask the shop you purchased the product for inspection if any defect in product is suspected. We don't accept

the order of fixing because Defi products require installation and wiring to the vehicle. In case you cannot go to the

shop you purchased because of move-out or closure of shop, please ask the nearest Defi Distributor listed in the

Defi website.

For a repair/inspection service, take the warranty card and customer contact information with you.

Please conduct periodic inspections by Defi through a shop which sells Defi products or Defi’s official distributor

every five years. Inspection is available at an additional cost. In the case you purchase used products or used

vehicles with products of Defi, please have an inspection by Defi as well before using them.

■Label

The label sticked on the product is for the product traceability. Do not peel it off.

■Repairing

When a repair is necessary, we will return the inspection result report through the store to you. After receiving a

repair service request, we start repairing. Ask the store how much it costs and how long it takes to repair.

■Discarding the products

Please dispose products in accordance with disposal laws, state laws and local government. A recycle label on the

package indicates that the package is recyclable.

Except in the case of defects, we shall not be liable for any trouble including violation, accident or improper

wiring resulting from using this product.

The warranty does not cover any unauthorized repair performed or caused to be performed by the end user.

Such action can destroy or damage this product.

DF07801

DF07802

DF07901

DF07902

DF08001

DF08002

DF08101

DF08102

DF08201

DF08202

DF08301

DF08302

DF08401

DF08402

DF08501

DF08502

DF08601

DF08602

DF08701

DF08702

DF08801

DF08802

DF08901

DF08902

DF09001

DF09002

DF09101

DF09102

DF09201

DF09202

DF09301

DF09302

DF09403

DF09404

Φ 52 series

■CR gauges (SI models)

Φ 60 series

Lineup (for customer)

Product Name

Product No.

Defi-Link ADVANCE Control unit

DF07703

Defi-Link Meter ADVANCE CR and ADVANCE BF need to be used with the advance control unit.

One advance control unit can control up to 7 gauges.

Do not connect more than one gauge of the same variety. (Ex. You can NOT connect 2 turbo gauges together.)

*In-Mani Press is an abbreviation of Intake Manifold Pressure.

Product name

Turbo2.0

Turbo1.2

In-Mani Press *

Oil Press

Fuel Press

Oil Temp

Water Temp

Exhaust Temp

Tachometer

■BF gauges Φ 60 series (SI models)

Product name

Display range

White Model Amber Red Model

Turbo2.0

Turbo1.2

In-Mani Press *

Oil Press

Fuel Press

Oil Temp

Water Temp

Exhaust Temp

Tachometer

DF09901

DF10001

DF10101

DF10201

DF10301

DF10401

DF10501

DF10601

DF10704

DF09902

DF10002

DF10102

DF10202

DF10302

DF10402

DF10502

DF10602

DF10705

Blue Model

DF09903

DF10003

DF10103

DF10303

DF10403

DF10503

DF10603

DF10203

DF10706

-100∼ +200kPa

-100∼ +120kPa

-100∼ +20kPa

0 ∼ 1000kPa

0 ∼ 600kPa

50 ∼ 150℃

20 ∼ 120℃

200 ∼ 1100℃

0 ∼ 9000rpm

Display range

-100∼ +200kPa

-100∼ +120kPa

-100∼ +20kPa

0 ∼ 1000kPa

0 ∼ 600kPa

50 ∼ 150℃

20 ∼ 120℃

200 ∼ 1100℃

0 ∼ 9000rpm

■BF gauges Φ 2 3/8” series (USDM models)

Product name

Display range

Amber Red Model

Boost

Oil Press

Fuel Press

Oil Temp

Water Temp

Exhaust Temp

DF09904

DF10204

DF10304

DF10404

DF10504

DF10604

-30inHg∼ +29PSI

0 ∼ 145PSI

0 ∼ 87PSI

122 ∼ 302 °F

68 ∼ 248 °F

392 ∼ 2010 °F

White Dial

Black Dial

White Dial

Black Dial

■ Factory default settings of warning values