Service instructions, General, Belt replacement – L.B. White 350 Premier User Manual

Page 15

Service Instructions

1. Close the fuel supply valve to the heater and

disconnect the electrical supply before servicing

unless necessary for your service procedure.

2. Clean the heater’s orifice with compressed air or a

soft, dry rag. Do not use files, drills, broaches, etc. to

clean the orifice hole. Doing so will enlarge the hole,

causing combustion or ignition problems. Replace

the orifice if it cannot be cleaned properly.

3. The high limit switches, HEAT/VENT switch, and

thermostat can be tested by disconnecting the leads

at the component, and jumpering the leads together.:

-- Reconnect the electrical supply and open fuel

supply valves.

-- If the heater lights, the component is defective

and must be replaced.

-- Do not leave the jumper on or operate the heater if

the part is defective. Replace the part immediately.

-- An alternate method for checking the components

is to perform a continuity check..

4. The air proving switch must not be jumpered. If

jumpered, the ignition control will not allow heater

operation. Test the air proving switch for continuity. If

defective, replace the switch

5. Open the respective case panel for access to burner

or fan related components.

6. For reassembly, reverse the respective service

procedure. Ensure gas connections are tightened

securely.

7 After servicing, start the heater to ensure proper

operation and check for gas leaks.

8. If sheave or fan keys are lost during ser vice,

replacements are made by using 3/16 square x 1 in.

bar stock. Otherwise, order Part #22955.

WARNING

B

Buurrnn H

Haazzaarrdd

■

Heater surfaces are hot for a period of time after the

heater has been shut down.

■

Allow the heater to cool before performing service,

maintenance, or cleaning.

■

Failure to follow this warning will result in burns

causing injury.

WARNING

FFiirree aanndd EExxpplloossiioonn H

Haazzaarrdd

■

Do not disassemble or attempt to repair any heater

components or gas train components.

■

All component parts must be replaced if defects are

found.

■

Failure to follow this warning will result in fire or

explosions, causing property damage, injury, or death.

GENERAL

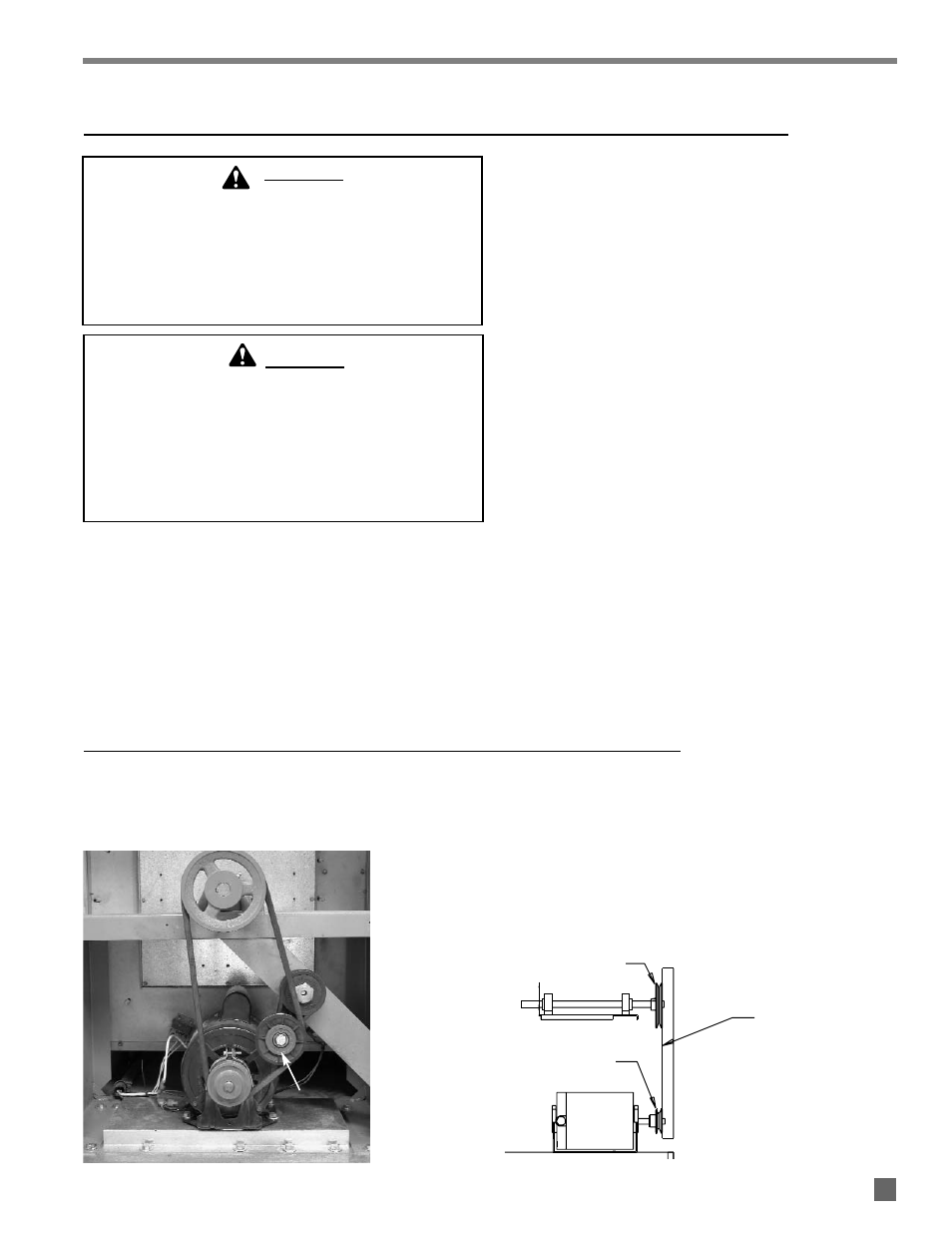

1. Push the belt tensioner clockwise for removal of the

belt from pulley. See Fig. 11.

FIG. 11

2

Check the fan and motor pulley grooves for dirt Clean

the pulleys if needed.

3. Install new belt. Using a straight edge, check motor

and fan pulley alignment. Contact must be made at

edges of both pulleys. See Fig. 12.

FIG. 12

BELT REPLACEMENT

TENSIONER

STRAIGHT

EDGE

FAN SHEAVE

MOTOR SHEAVE

FAN PULLEY

MOTOR PULLEY

14