Igniter and flame sensor, Fig. 23, Fig. 24 – L.B. White AD100 User Manual

Page 18

■

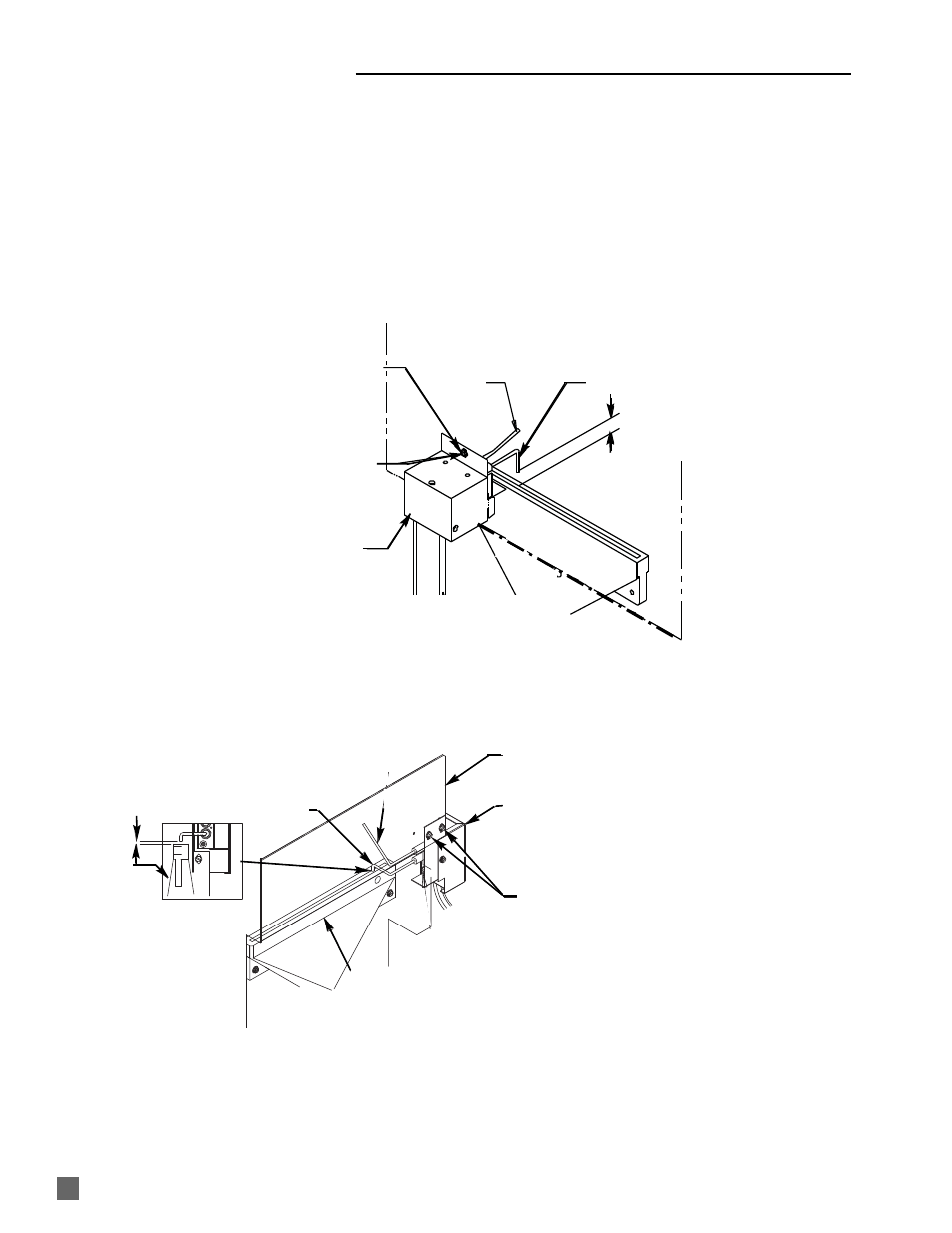

Refer to Fig.23 (AD100) or Fig.24 (AD060) for servicing

of the igniter assembly.

■

The igniter/sensor assembly may require cleaning due

to accumulations of dust and dirt over a period of

time, affecting its ability to ignite fuel gas and sense

burner flame. Cleaning will require igniter/sensor

removal.

--

If spark appears to be weak, rub the igniter

electrode with emery cloth or steel wool to remove

any buildup.

--- If the spark appears strong but the heater cycles

off, rub the sensor rod with emery cloth or steel

wool to remove any build-up.

■

Ensure the igniter gap is .15 in. and the igniter tip is

positioned over the burner port according to the

illustration below.

IGNITER AND FLAME SENSOR

SENSOR

IGNITER

2.5 mm - 4.5 mm

HEAT CHAMBER FACE

BURNER

IGNITER LEAD

SENSOR LEAD

IGNITER / SENSOR

ENCLOSURE

TO REMOVE IGNITER / SENSOR WITH ENCLOSURE

REMOVE SCREW, LIFT ASSEMBLY

FROM ITS MOUNTING SLOTS

TO GAP IGNITER LOOSEN SCREW.

MOVE ENCLOSURE UP OR DOWN

TO ALLOW PROPER POSITIONING

OF IGNITER TO BURNER.

FIG. 23

.15 in.

17

BURNER

17,6 kW: 3 mm

65,9 kW: 4 mm

IGNITER

FLAME SENSOR

REMOVE SCREW (65,9 kW MODEL ONLY)

REMOVE SCREWS

IGNITER/SENSOR

ENCLOSURE

BURNER

HEAT CHAMBER

LOOSEN SCREWS AND SLIDE IGNITER

UP/DOWN TO MAINTAIN PROPER GAP.

REMOVE SCREWS AS NEEDED FOR

SERVICING IGNITER ASSEMBLY

BURNER

BURNER

IGNITER / SENSOR

ENCLOSURE

HEAT CHAMBER

IGNITER

.15 in.

LOOSEN SCREW AND SLIDE

ASSEMBLY UP/DOWN TO MAINTAIN

PROPER GAP.

REMOVE SCREW AND SLIDE THE ENCLOSURE’S

MOUNTING TABS FROM SLOTS IN HEAT CHAMBER.

IGNITER ENCLOSURE

SENSOR

IGNITER

HEAT CHAMBER

BURNER

FLAME SENSOR

FIG. 24