Maintenance, Troubleshooting – Steele Products SP-PB006 User Manual

Page 6

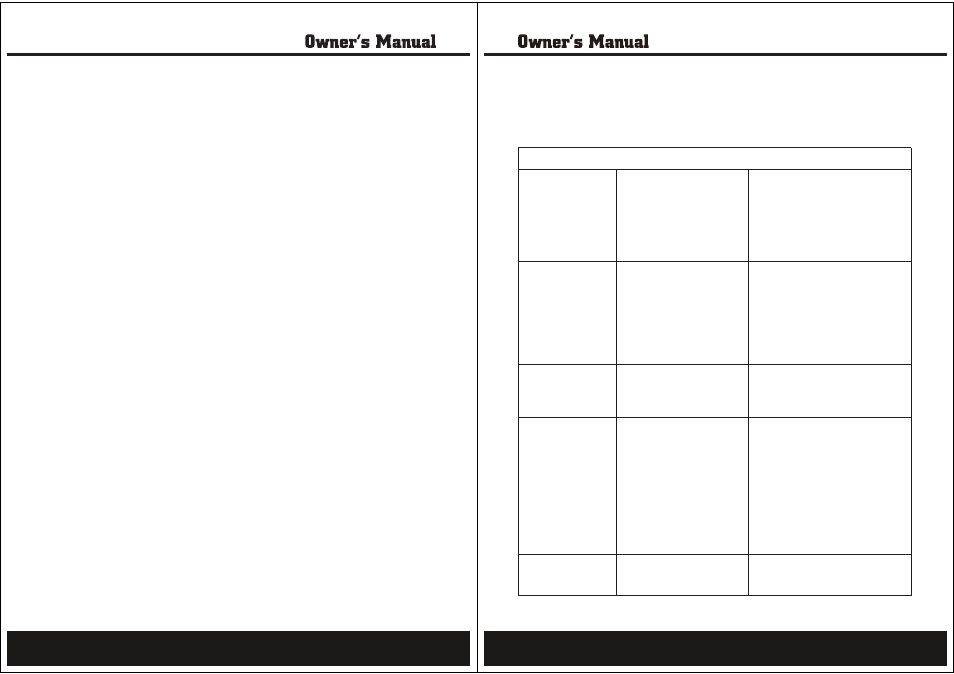

MAINTENANCE

11

Maintenance

Required Frequency

1. Check power cord

Before each use.

2. Check wheels for cracks

Before each use.

3. Check moving parts for alignment and binding issues

Before each use.

5. Dress grinding wheels

As needed.

4. Check the worklight

Before each use.

6. Replace grinding wheels (see manual section for specifics)

As needed.

7. Clean and vacuum dust from the motor housing and other grinder parts As needed.

Service beyond recommended maintenance on these tools should only be performed by an

authorized, qualified technician.

TROUBLESHOOTING

12

Service on these tools should only be performed by an authorized, qualified technician.

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Motor will not start.

1.Low Voltage.

2.Open circuit in motor or loose

connections.

3.Blown fuse or breaker.

1.Check power source for proper voltage.

2.Inspect all lead connection on motor

for loose or open connections.

(Send for Servicing.)

3.Short circuit.(Send for Servicing.)

4.Improper match between tool and

circuit, fuse or breaker.

Motor will not start

-fuses or circuit breakers

tripping or blowing.

1.Short circuit in line, cord or

plug.

2.Short circuit in motor or loose

connections.

3.Incorrect fuses or circuit

breakers in power line.

1.Inspect cord or plug for damaged

insulation and shorted wires.

2.Inspect all connections on motor for

loose or shorted terminals and/or

worn insulation.

3.Install correct fuses or circuit breakers

or switch tool to an appropriately

sized circuit.

Motor overheats.

4.Motor overloaded.

5.Extension cord too long and

of insufficient gauge (weight).

4.Reduce load on motor.

5.Utilize an extension cord of

appropriate gauge and length or

plug tool directly into outlet.

Motor stalls (resulting

in blown fuses or

tripped circuit).

1. Short circuit in motor or

loose connections.

2. Low voltage

3. Incorrect fuses or circuit

breakers in power line.

4. Motor overload.

1.Inspect connections on motor for

loose or shorted terminals or worn

insulation. (Send for Servicing.)

2.Correct low voltage conditions

(for example: improper extension

cord length and/or gauge).

3.Install correct fuses or circuit

breakers or plug tool into an

appropriate circuit, matched to

an appropriate fuse or breaker.

4.Reduce the load on the motor.

Machine slows

when operating.

1.Reduce the rate at which the workpiece

1.Feed rate too great.

is fed into the working area of the tool

the tool (grinding wheel).