Ball bearings – Hale CSD User Manual

Page 16

d) Pull a prime until the compound gauge reaches about 20 inches of vacuum.

e) Watch gauge - if vacuum drops more than one inch in 10 minutes, an air leak is present. All air

leaks must be corrected before the pump may be considered fully serviceable.

Ball Bearings

Ball bearings are the most common anti-friction bearings used today and offer a major contribution

to the life of a fire pump, during major maintenance you will have an occasion to remove or replace

ball bearings. Often an attempt is made to reuse them and sometimes they can be; however, when

doing so you are taking a serious gamble, particularly when you have invested a great deal of time

and money to dismantle, repair and reinstall the equipment only to have a bearing fail after a few

short hours of operation, again requiring further downtime and additional money spent. We do not

recommend this practice under any circumstance, however, we realize at times this must be

considered, when doing so they must be examined very carefully for pits, abrasion or other

damage, check the raceways very carefully for metal transfer and pits. When cleaning ball

bearings, be sure to use clean solvent; do not use contaminated solvent. Use clean air to blow the

solvent and foreign matter from the inside raceway, do not hold the inner race rigid and spin the

outer race with air pressure; this can cause metal transfer or embed small particles. Hold both

inner and outer races and blow through the open sections around the separation. After examination

and the bearing appears to be satisfactory, lubricate the raceway with light oil and then holding the

inner race between the fingers slowly rotate the outer race and feel for any catch, rough spots or

binds. If any are found then discard the bearing and secure a correct replacement. Your best

supply for the correct type and size is the pump manufacturer. If locally supplied bearings are used,

be sure it is an exact replacement. Do not interchange bearing types; they may also fail

prematurely.

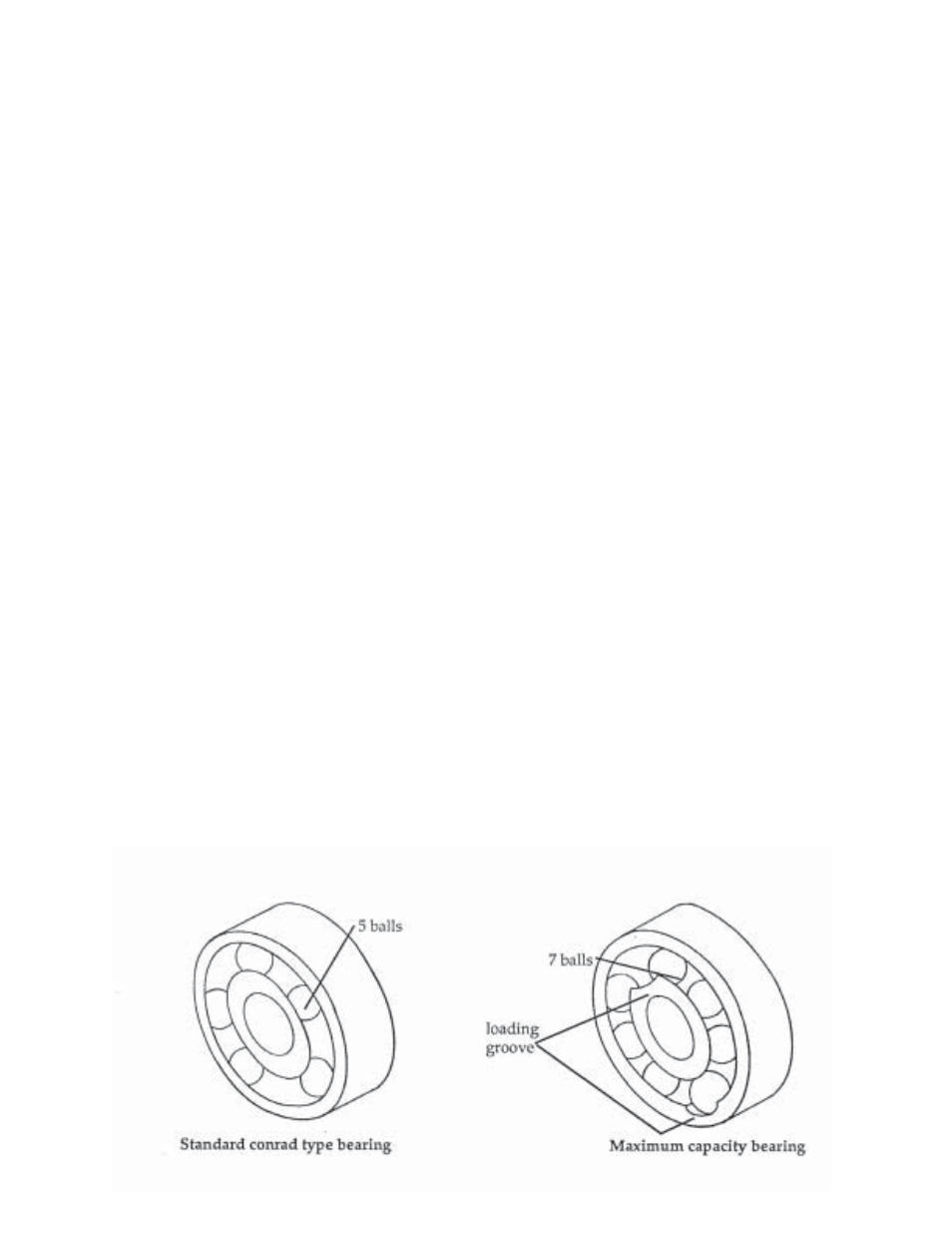

We have sketched two similar bearings that have the same outside diameter, same inside diameter

and the same width, but if one of these bearings is used to replace the other one you may be

asking for trouble. Design engineers and bearing manufacturers have spent a great deal of time

and effort to achieve the correct combinations of loads, speeds and other contributing factors to

assure long and dependable service. When a bearing is inadvertently or hastily replaced without

due consideration, you should not expect your equipment to operate as designed.

The standard Conrad type bearing shown on the left contains five balls and is a so-called standard

bearing. It will withstand moderate radial and combined thrust loads; however, the maximum

capacity bearing shown on the right contains more balls due to the loading groove and will

withstand considerable higher radial loads but less thrust loading. This bearing can replace the

Conrad type when very little or no thrust load is present; however, never replace the maximum type

with a standard Conrad type, when a bearing has the loading groove as shown, it most certainly

indicates high radial and very little thrust loads are present.