Hale Rear Mount User Manual

Page 15

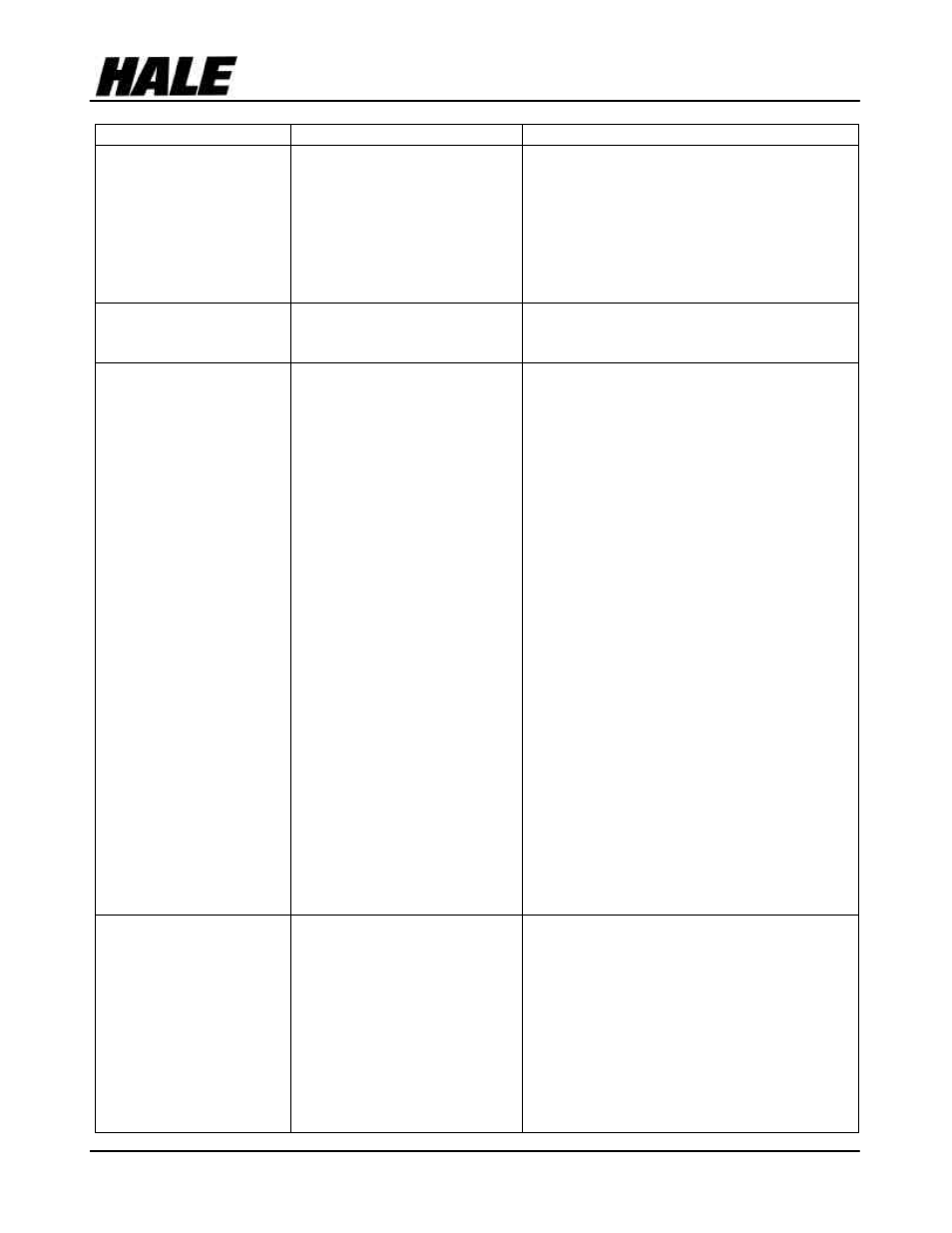

CONDITION

POSSIBLE CAUSE

SUGGESTED CORRECTION

LEAK AT PUMP

PACKING

Packing out of adjustment or

worn.

Adjust the packing per the procedure in

Section 3 of this manual (8 to 10 drops per

minute leakage at 150 PSI (10 BAR)

preferred).

Replace pump packing per Section 3 of this

manual. Packing replacement is recommended

every 2 or 3 years depending on usage.

REMOTE CONTROL

DIFFICULT TO

OPERATE

Lack of lubrication

Lubricate the remote control linkages and

collar with oil.

ENGINE SPEEDS TOO

HIGH FOR

REQUIRED

CAPACTICTY OR

PRESSURE

Impeller blockage

Worn pump impeller(s) and

clearance rings

Blockage of suction hose entry

Defective suction hose

Lift too high, suction hose too

small

Truck transmission in wrong

range or gear

Blockage in the impeller can prevent loss of

both capacity and pressure. Back flushing of

pumps from discharge to suction may free

blockage. Removal of one half of the pump

body may be required (this is considered a

major repair).

Installation of new parts required.

Clean suction hose strainer of obstruction and

follow recommended practices for laying

suction hose. Keep off the bottom of the water

supply but a least 2 feet below the surface of

the water.

Inner line of suction hose may collapse when

drafting and is usually undetectable. Try a

different suction hose on same pump; test for

comparison against original hose.

Higher than normal lift (10 feet) will cause

higher engine speeds, high vacuum and rough

operation. Use larger suction hose.

Check recommended procedures for correct

transmission selection; see Section 3 and

truck manual.

RELIEF VALVE DOES

NOT RELIEVE

PRESSURE WHEN

VALVES ARE

CLOSED

Incorrect setting of Control

(Pilot) Valve

Relief Valve inoperative

Check and repeat proper procedures for

setting relief valve system. (see Section 3)

Possibly in need of lubrication. Remove relief

valve from pump; dismantle; clean and

lubricate. Weekly use of the Relief Valve is

recommended.