Hale DSD User Manual

Page 7

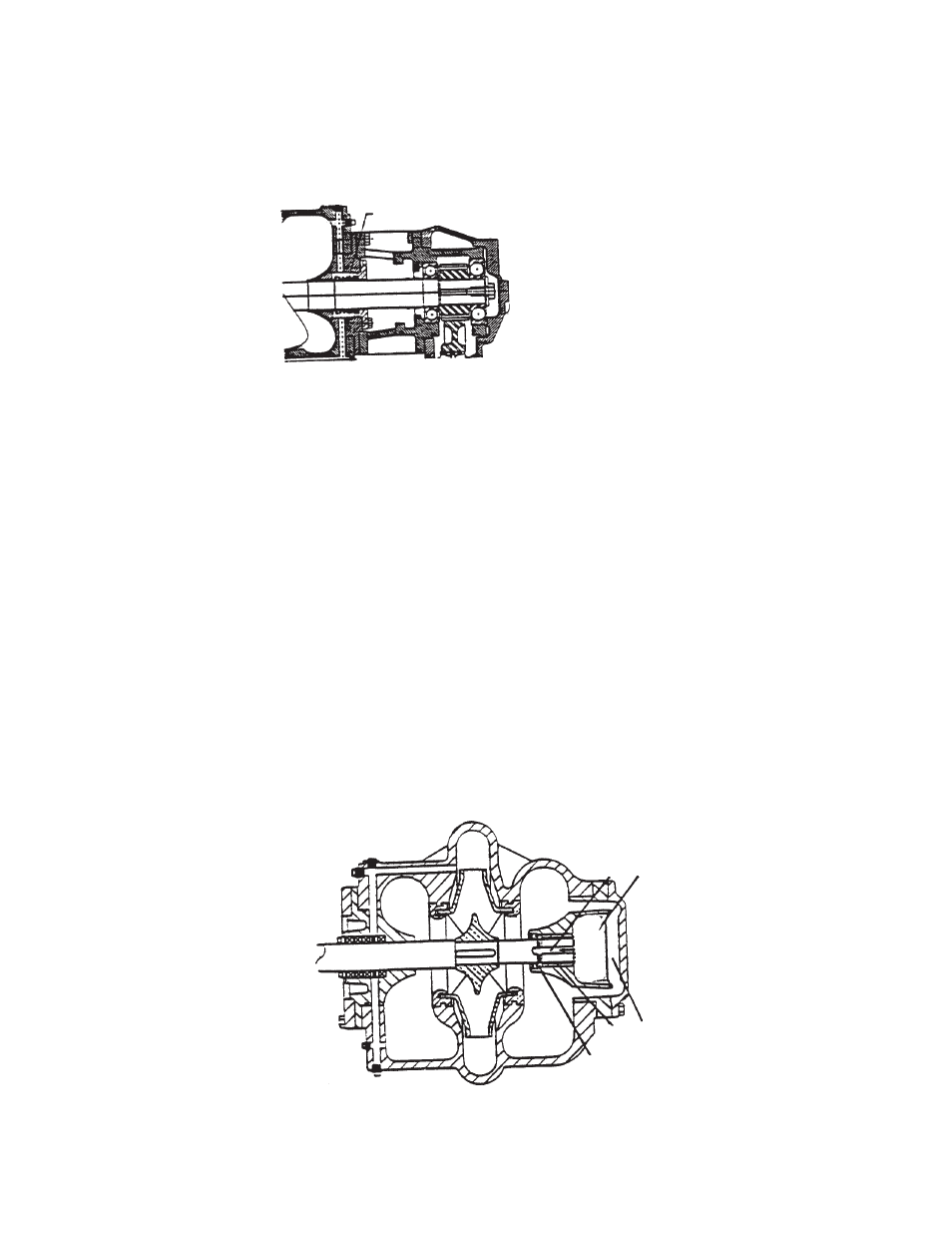

Mechanical Seal

The mechanical seal is an option to pump packing. As shown m Figure 1-5, a stationary seal seat is in

constant contact with a rotating carbon face to prevent high pressure leakage. The sealing boot is made

of a rubber elastomer that is specifically designed for high temperature operation.

Auto-Lube

A miniature centrifugal pump (A) is built into the shaft of Hale midship pumps (see Figure 1-6).

This miniature pump continuously forces oil from the reservoir (B), through the bearing (C), and

back again.

A balancing chamber (D) behind the oil reservoir is connected by a passage to the inlet side of

the pump. This chamber always keeps the pressure in the oil reservoir equal to water pressure

- whether you are pumping at high inlet pressure or pulling vacuum

The miniature pump adds enough extra pressure to constantly keep the flowing oil a few PSI

higher than water pressure Thus, oil pressure inside the double lip-type seal (E) is always

slightly higher than water pressure outside. Dirt and water are repelled by this higher pressure.

Auto-Lube does more than just fight off dirt. It ensures continuous lubrication, even when you

are pumping dry. It cools the bearing, because water chambers surround the water reservoir. It

permits the use of a compact, double lip-type oil seal, and maintains a constant film of oil

under this seal to prevent shaft wear. Because it is built into the main pump body, it completely

eliminates the need for high pressure packing.

MECHANICAL SEAL

A B

C D

E

Figure 1.6 - Auto-Lube System