Wire burner – Beckett AFII User Manual

Page 9

9

AFII Burner Manual

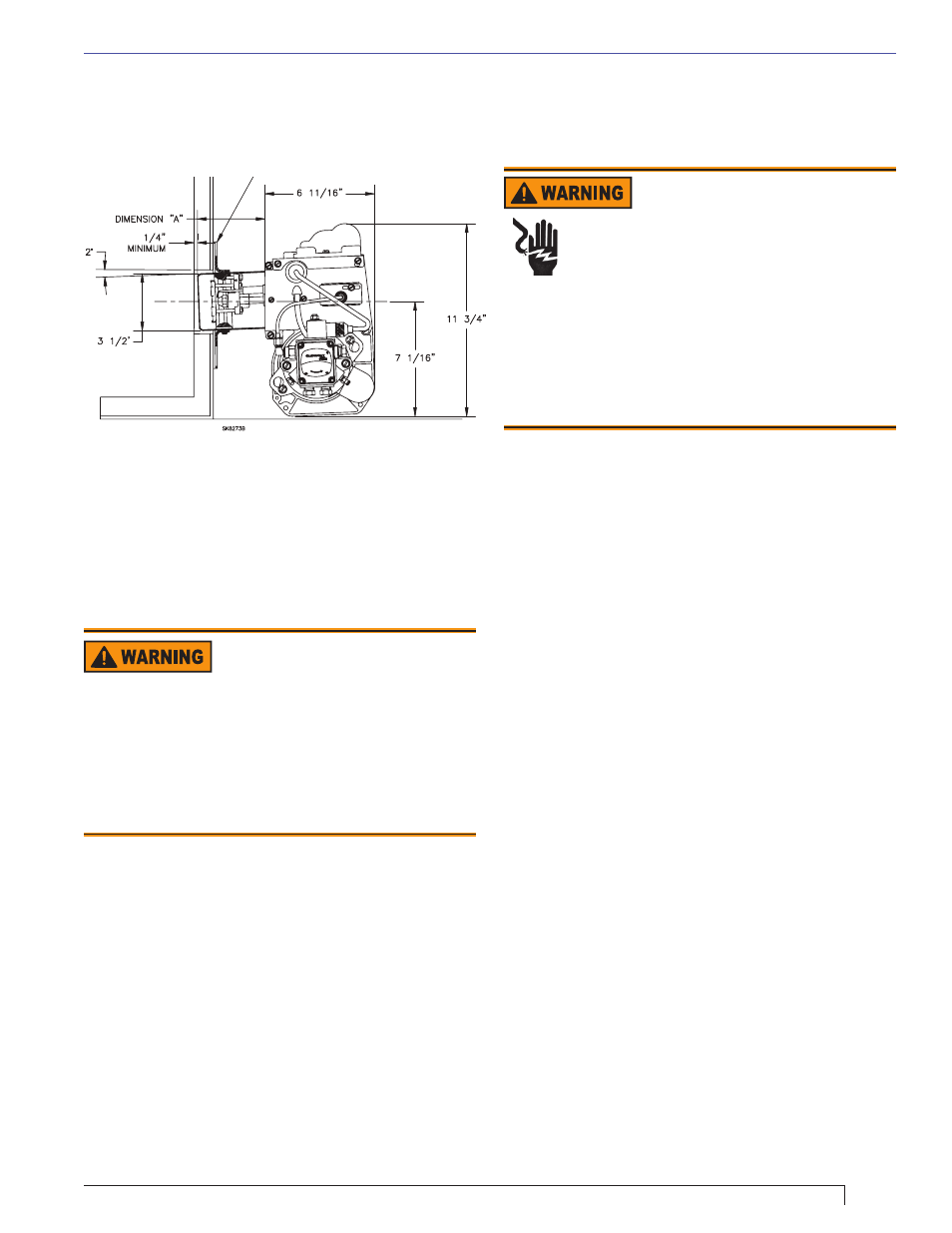

Figure 6. – Mounting Burner in Appliance

3 GPH 150-200 PSI 3450 R

PM

4 GPH

GPH 100-150

100-150 PSI

PSI 3450

3450 RPM

RPM

BY-PASS

INLET

A2EA-6520

A2EA-6520

NO. 2 & LIGHTER FUEL

Exclusively for Beckett

NO. 2 FUEL

Made by Suntec

Made by Suntec

INLET

Beckett

USE

USE ONLY

ONLY WITH

WITH

VALVE ON DELAY

Section: Mount Burner on Appliance & Wire Burner

Mount Burner on Appliance

Verify that the air tube installed on the burner provides

the correct insertion depth. Refer to Figure 6.

Wire Burner

Burner packaged with appliance

Disconnect electrical power before installing or

servicing the burner.

Provide ground wiring to the burner, metal control

enclosures and accessories. (This may also be

required to aid proper control system operation.)

Perform all wiring in compliance with the National

Electrical Code ANSI/NFPA 70 (Canada CSA C22.1)

y

y

y

Electrical shock can cause severe

personal injury or death.

Electrical Shock Hazard

Refer to appliance manufacturer’s wiring diagram for

electrical connections.

Burner installed at jobsite

Refer to Figures 8a and 8b, for typical burner wiring,

showing cad cell primary controls. Burner wiring may

vary, depending on primary control actually used.

Refer to the appliance manufacturer’s wiring

diagram prior to connecting the burner wiring. All

wiring must be in accordance with the latest revision

of National Electric Code NFPA 70 and all local

codes and regulations. In Canada, all wiring is to be

in accordance with the Canadian Electrical Code,

Part 1.

The 7505 primary control with valve-on delay (pre-

time) and burner motor-off delay (post-time) requires

a constant 120 volts AC power source supplied to the

BLACK wire on the control. The RED wire goes to the

appliance limit circuit. Please note that other control

manufacturers may use different wire colors for power

and limit connections.

Special wiring required with covered burners

The mounting plate is not a conduit connection point.

Pass conduit and attached connector through the

opening in the mounting plate and attach it directly to the

burner-mounted 4x4 electrical box.

If attaching a burner cover to a previously installed

burner, attach the mounting plate and then slide the

conduit into the “J” shaped conduit slot.

○

○

○

The end of the air tube should normally be 1/4” back from

the inside wall of the combustion chamber. Never allow the

leading edge of the retention ring to extend into the chamber,

unless otherwise specifi ed by the appliance manufacturer.

Bolt the burner to the appliance using the factory-welded

fl ange.

Connect Fuel Lines

The burner is shipped without the by-pass plug

installed.

Install the by-pass plug in two-pipe oil supply

systems ONLY.

y

y

Failure to comply could cause Immediate pump seal

failure, pressurized oil leakage and the potential for a

fi re and injury hazard.

Do Not Install By-pass Plug

with 1-Pipe System

The burner is supplied with either a one-stage pump

or a two-stage pump based on the oil supply system

requirements. Consult the instructions provided with the

pump for installation specifi cations.

When installing a one-pipe system, connect the inlet

line to the pump inlet. The fuel pump may be installed

with gravity feed or lift. The maximum allowable lift for a

single pipe installation is 8 ft.

When installing a two-pipe system, remove the 1/16”

pipe by-pass plug from plastic bag attached to fuel unit.

Remove 1/4” plug from return port. Insert and tighten

the by-pass plug. Attach return and inlet lines. The

return line should terminate approximately 3 to 4 inches

above supply line inlet. Failure to do this may introduce

air into the system and could result in loss of prime.