Bush Hog RTS User Manual

Page 13

12

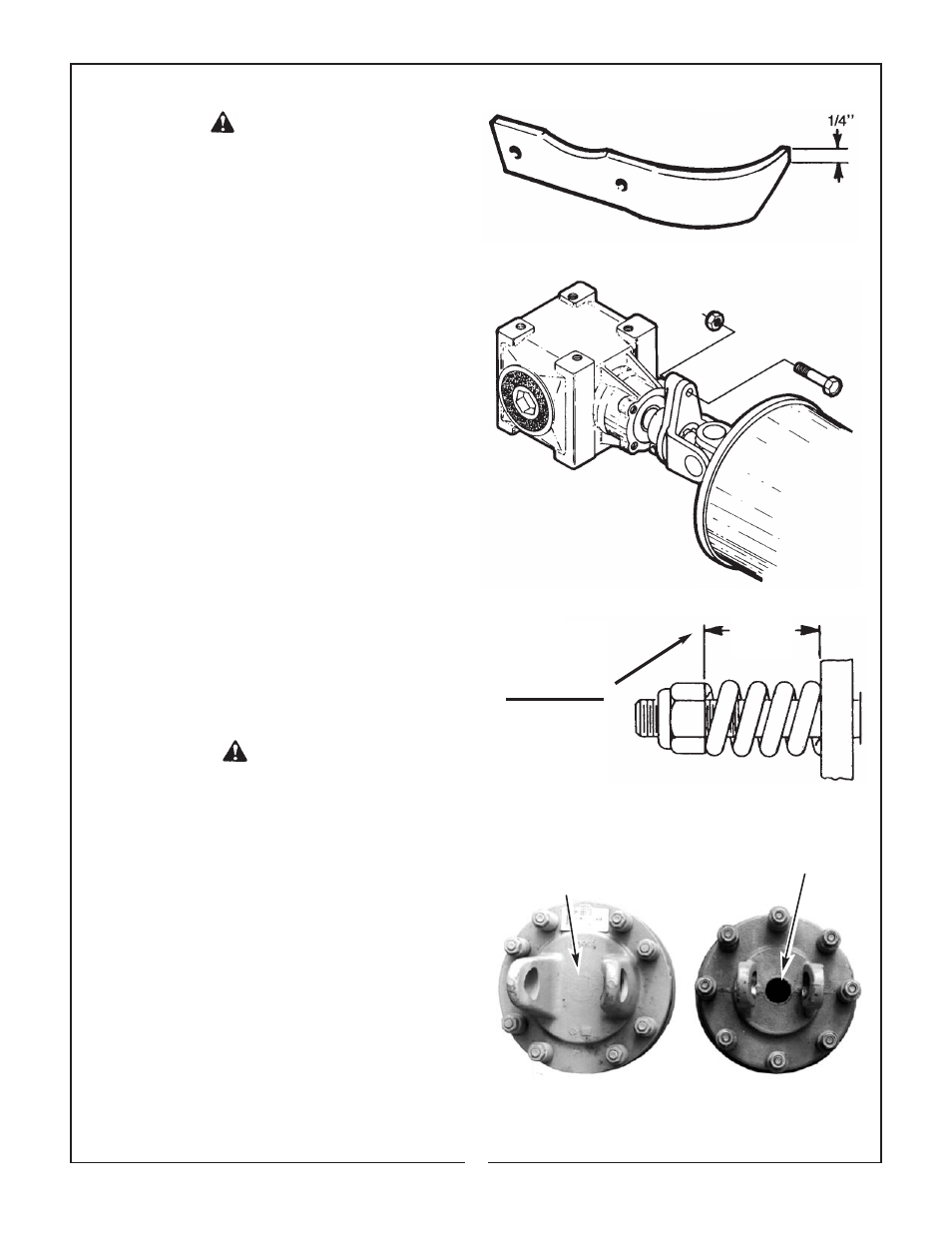

Figure 4-2 Blade Wear

Figure 4-3 Shear Bolt

Figure 4-4 Spring Length

Spring

Length

Bondioli & Pavesi

or

Binacchi

1.12”

(28.6 mm)

EG/Comer

1.25”

(31.8 mm)

Figure 4-5 Slip Clutch Identification

Bondioli & Pavesi EG

or Binacchi (Holes Through Center)

(Solid Casting)

4-6 SLIP CLUTCH ADJUSTMENT

The slip clutch is factory preset to the correct torque

for protecting implement and tractor. Periodic adjust-

ment is recommended; refer to section 4-5. Should

adjustment be needed, first check to be sure all

spring lengths are within 1/64” of being the same.

Initial spring lengths are shown in figure 4-4. If neces-

sary, loosen nut on any spring that is unequal. Adjust

all eight spring retaining nuts 2/3 of a turn (2 flats on a

nut) and check clutch slippage. If further adjustment is

necessary, do so in 1/3 turn increments or consult

your Bush Hog dealer. Adjust only to provide suffi-

cient torque to prevent slippage under normal condi-

tions. When rocks, roots, etc. are present, occasional

slippage is normal for drivetrain protection.

CAUTION

FAILURE TO RETIGHTEN SPRING NUTS

TO ORIGINAL POSITION MAY CAUSE

DAMAGE TO TILLER AND/OR TRACTOR

DUE TO IMPROPER SLIP CLUTCH

TORQUE SETTING.

4-3 BLADE REPLACEMENT

Tiller blades should be replaced when they have

approximately 1/4” of wear left on tip of blade.

(Figure 4-2) To replace blades, remove bolts secur-

ing blade. Install new blade. Blade must be a right or

left corresponding to blade removed. Tighten blade

bolts to 73 ft./lbs. Use only genuine Bush Hog

replacement parts.

4-4 BOLT REPLACEMENT

A. Slide yoke shield back. (Figure 4-1)

B. Drive out sheared bolt with hammer and punch.

C. Align holes and install new shear bolt. Use only

genuine Bush Hog replacement shear bolt. (Figure 4-3)

D. Slide yoke shield securely in place.

4-5 SLIP CLUTCH OPERATIONAL CHECK

After tiller has been stored for an extended period of

time, perform the following operational check:

A. Loosen eight nuts retaining clutch springs exactly

one full turn.

B. With tiller blades firmly on ground and tractor at

idle speed, engage tractor PTO drive 2-3 seconds.

Clutch should slip without turning blades. If clutch does

not slip, contact your authorized Bush Hog dealer.

C. Retighten nuts to within 1/64” of original position.

Initial spring length is shown in Figure 4-4.

WARNING

THE TILLER CAN FALL FROM HYDRAULIC

SYSTEM FAILURE. TO AVOID SERIOUS

INJURY OR DEATH, SECURELY SUPPORT

TILLER BEFORE WORKING UNDERNEATH.