State-of-the-art chassis and drive technology, High mobility and cost effectiveness, Compact, agile and weight-optimised – Liebherr LTM 1040-2.1 User Manual

Page 5

LTM 1040-2.

1

5

36

0

0

19°

8528

10915

500

6305

25

50

430

0

6000

S2381.04

10608

12°

3300

6305

R = 6

560

R = 3

330

R = 7695

R = 8

050

445/95 R 25 (16.00 R 25) 12 t

12 t

State-of-the-art chassis and drive technology

Hydro-pneumatic suspension

“Niveaumatik”

• Maintenance-free suspension cylinders

• Large dimensions to cope with high

axle loads

• Suspension travel +100/-100 mm

• High lateral stability when cornering

• Choice of driving states using fixed

programmes

High mobility and cost effectiveness

A powerful six-cylinder turbo diesel engine with 205 kW/278 HP ensures swift

driving performance. The ZF-power shift gearbox with automatic gear changing

provides best maneuverability and high comfort.

• Minimum crawling speed by torque converter

• ABV automatic locking preventer with ASR drive slip control

• Crab steering

• Telma eddy current brake optional, wear free and comfortable

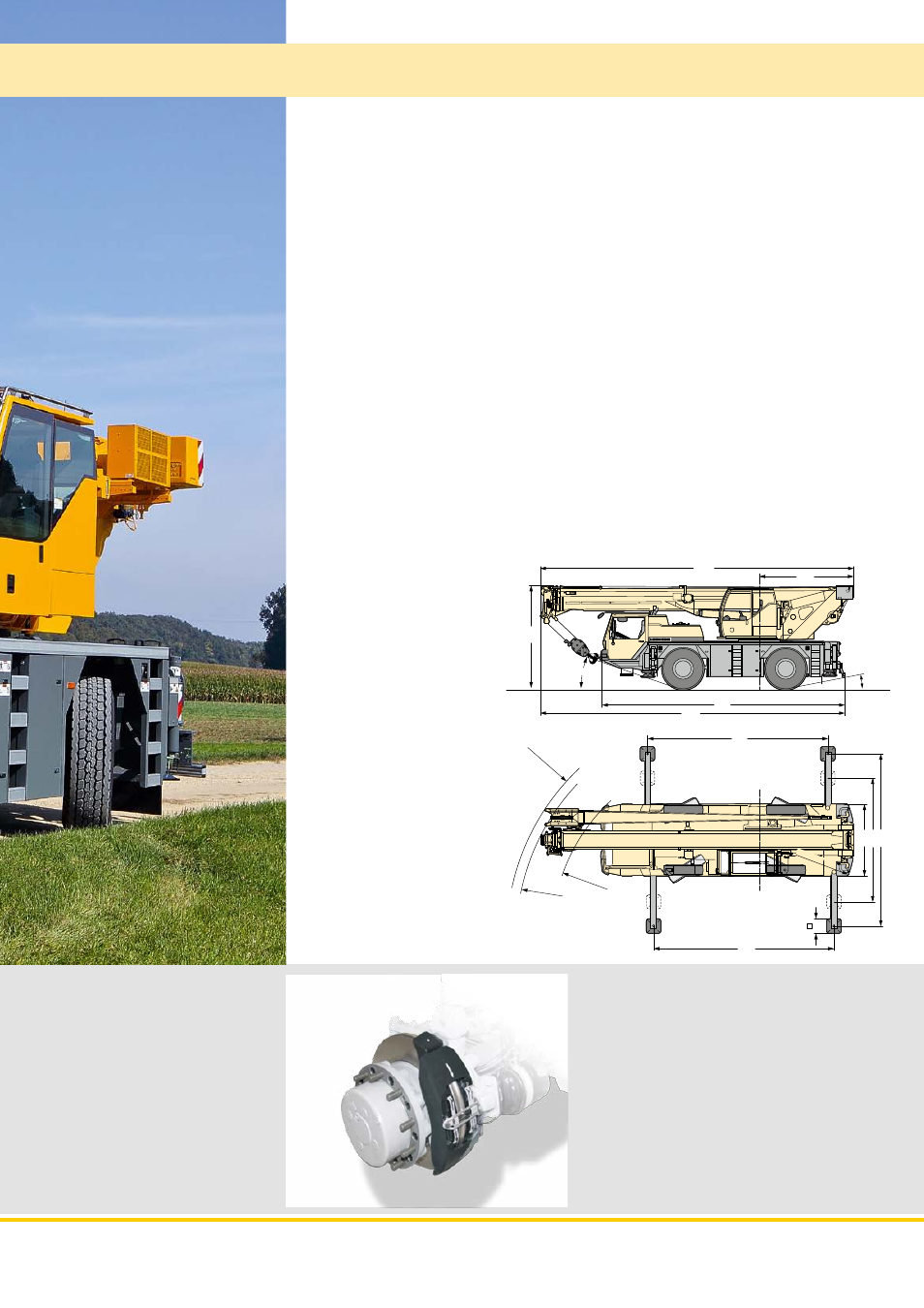

Compact, agile and weight-optimised

Thanks to its extremely compact design, the LTM 1040-2.1 can operate on the

smallest of construction sites. At an axle load of 12 t it can drive with up to 1.5 t

ballast making it flexible and economical to use.

• Chassis length only 8.53 m

• Smallest turning radius only 6.56 m

• Chassis width only 2.55 m, even with 445/95 R 25 tyres (16.00 R 25)

• Tail swing radius only 3.33 m

Pneumatic disc brakes

• High braking power, improved control

• Improved directional stability

• No reduction of braking force at high braking

temperatures (fading)

• Longer service life

• Shorter labour times for changing the braking

pads

• Brake pads with wear indicators