Reliability, Liebherr drive train, Robust steel structure – Liebherr PR 744 Litronic User Manual

Page 9: Solutions for a long lifetime

9

PR 734 Litronic PR 744 Litronic

Reliability

Due to their high quality and excellent engineering, these machines offer maximum

availability. Components developed by Liebherr specifically for use in construc-

tion machinery guarantee operational reliability in even the toughest conditions.

Liebherr drive train

Durable engine

Liebherr diesel engines were developed for the most

demanding conditions of use. Their low rated speed

ensures high operational reliability and a long life-

time.

Fewer components

The proven hydrostatic travel drive means that

mechanical components such as a torque converter,

manual gearbox and differential steering or clutches

are not required. Standardized hydraulic pumps and

motors are non-wearing and dependable in operation.

Robust final drive

The large Series 4 final drive is extremely robust and

is engineered to endure the highest loads. A double

gearbox seal with automatic seal monitoring offers

dependable protection.

Robust steel structure

Modular-design

main frame

The main frame is of the proven modular design,

resulting in high torsional rigidity and optimal

absorption of the forces to which it is exposed.

Components subjected to particularly heavy loads

are made of cast steel.

Solutions for a long lifetime

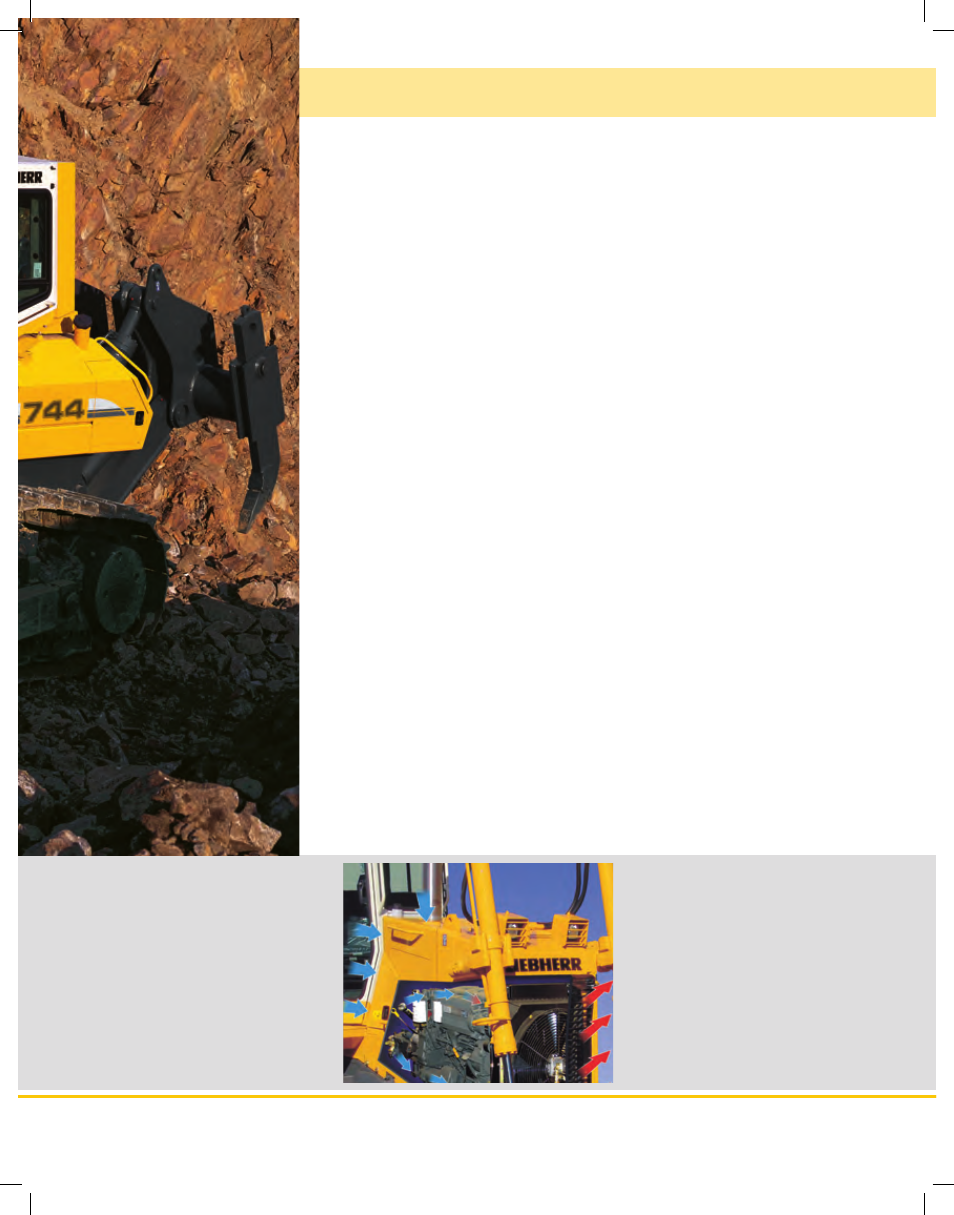

Innovative cooling

system

The electronically controlled suction-type fan con-

trols the operating temperature reliably and regard-

less of the engine speed. Extra-large radiator fins

ensure good self-cleaning.

Optimally protected

wiring harness

High-quality material for the protection of the wiring

harness and a well-designed layout ensure the func-

tional reliability of the machine.

Components in life-cycle tests

• FE analysis is used during the devel-

opment phase to design the com-

ponents, thereby ensuring that they

are optimally configured to withstand

heavy-duty use.

• The components are then subjected to

intensive long-term tests. Only parts

that meet the high quality standard are

used in the machines.

State-of-the-art cooling system

• The hydrostatically driven fan matches the

cooling performance to the cooling require-

ment, meaning that the engine reaches an

optimal operating temperature more quickly.

• Air is taken in from dirt-protected zones,

thereby minimizing contamination caused by

dust particles.

• Optional: Reversible fan for the quick cleaning

of the radiator in particularly dusty conditions.