Double rotary drilling description – Liebherr LRB 125 XL User Manual

Page 2

2

Double rotary drilling

Description

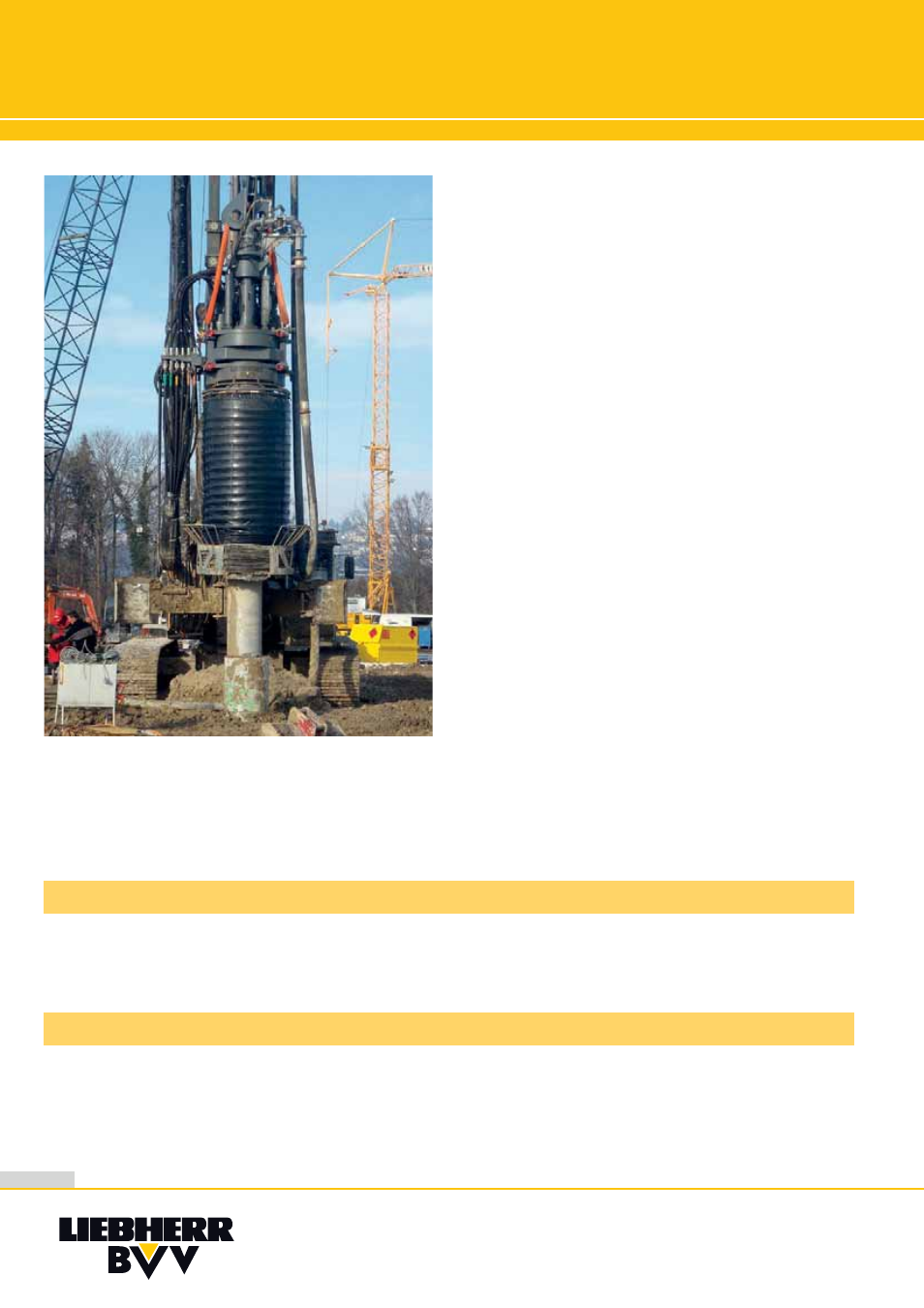

With pile production using double rotary drilling, an

outer casing and an inner auger (hollow auger) are

driven in counter-rotation by two independant rotary

drives which are mounted on a common carriage. The

outer casing provides support for the ground, while the

auger removes drilling cuttings up through the casing.

Once the final depth is reached, a concrete pump is

used to pump pumpable concrete via the hollow stem

of the auger inside the outer casing to the bottom

of the borehole. More concrete is pumped in under

simultaneous extraction of the casing and the auger

filled with drilling cuttings. The extraction speed is

selected as a function of the quantity of concrete and

the concrete pressure. In a further step a reinforcement

cage can then be inserted into the liquid concrete.

Soil types

Double rotary drilling is suitable for noncohesive soils

up to maximum density as well as cohesive soils up to

stiff consistency.

Advantages

• Suitable for nearly all soil types

• High productivity

• Very precise drilling

• Low noise level

• Low vibration

• Adjustment of casing and auger possible

• Drilling does not have to be carried out with water

injection