Technical data, Attachment, Electric motor – Liebherr ER 944 C High Rise User Manual

Page 7: Electric system, Hydraulic system, Hydraulic controls, Swing drive, Operator’s cab, Undercarriage

ER 934 C ER 944 C ER 954 C High Rise

7

ER

9

5

4

C

ER

9

4

4

C

ER

9

3

4

C

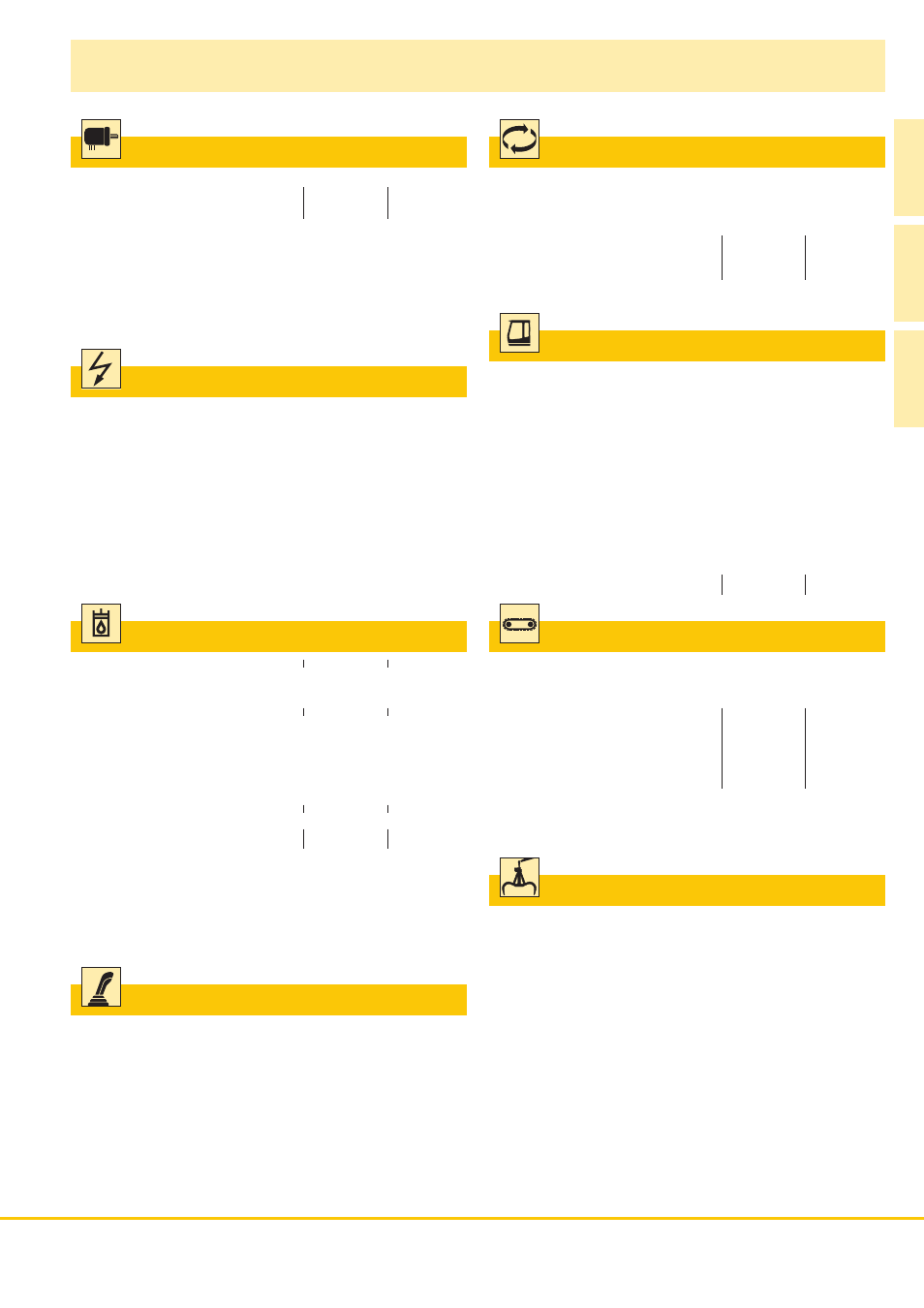

Technical Data

Attachment

Type

��������������������������������

high-strength steel for extreme stresses. Bearings

designed for optimum distribution of stresses

Hydraulic cylinders

���������������

Liebherr cylinders with end-of-travel shock

absorbing, fitted with guide and sealing joints

Pivots

�������������������������������

sealed, low maintenance

Lubrication

������������������������

centralised semi-automatic Liebherr lubrication

system

VarioLift

Plus

�������������������������

variable boom mounting positions for optimized

lift capacities

Electric Motor

Engine

������������������������������

induction motor dedicated definition Liebherr

934

944

954

Power rating

(as per CEI 34-1)

������������������

160 kW (218 HP) 200 kW (272 HP) 250 kW (340 HP)

Rated voltage

���������������������

400 V – 50 Hz *

Number of poles

������������������

4

Design type

�����������������������

horizontal axle B35

axle height 315 mm

Standard degree of protection

��

IP55

Insulation

��������������������������

class F

Cooling

�����������������������������

IC06

Heat protection for windings

Heat protection for bearings

Anti-condensation heating system resistors

Electric System

The 400 V electrical cabinet provides a degree of protection to IP55.

This houses the following components:

– Electrical cabinet – remote control inside the cab

– Star/delta starter for motor

– Outlets for supplying auxiliary elements: heating, climate control

– Overheat protection devices

– Integrated heating and ventilation

– Filtered booster

– Transformers – rectifier for 24 V control circuit

– Motor protection

– Auxiliary batteries: 2 x 135 Ah/12 V: secured functions: lighting for excavator/

attachment position (option)

– Connecting inside closed panel

– Equipment: slip ring collector

power connector

embedded cable reel

Hydraulic System

934

944

954

Hydraulic pump

for the attachment

����������

two Liebherr swash plate pumps with variable

output

Max. flow

���������������������

2 x 253 l/min.

2 x 305 l/min.

2 x 341 l/min.

Max. pressure

���������������

350 bar

Pumpenansteuerung

������������

electro-hydraulic, with electronic regulation by

power limit, minimum pump flow at max. pres-

sure, distribution of oil to different receptor

components proportional to demand

Hydraulic pump

for the swing drive

����������

reversible swash plate pump, in closed circuit

Max. flow

���������������������

170 l/min.

205 l/min.

205 l/min.

Max. pressure

���������������

370 bar

Hydraulic tank

��������������������

340 l

460 l

440 l

Hydraulic system

�����������������

550 l

710 l

790 l

Filtration

���������������������������

934: filter in the return circuit, with integrated fine

filter elements (5 μm)

944/954: 2 filters in the return circuit, with inte-

grated fine filter elements (5 μm)

Cooling

�����������������������������

radiator equipped with hydrostatic drive fan for

cooling the hydraulic oil and climate control

condenser

Tool Control

�����������������������

10 flow rates and pressures adjustable as option

for optional accessories

Hydraulic Controls

Power distribution

����������������

with the aid of hydraulic distributors with

integrated safety valves

Flow summation

������������

to boom stick and stick

Closed-loop circuit

���������

for uppercarriage swing drive mechanism

Control

Attachment and swing

�����

proportional by handling element in cross

operation

Travel

�������������������������

proportional by pedals or by lever

Additional functions

��������������

proportional by pedals or by toggle switch

* Other voltages and frequencies possible on request.

Swing Drive

Drive by

����������������������������

hydraulic swash plate motor with integrated

brake valves

Transmission

����������������������

Liebherr compact planetary reduction gear

Swing ring

�������������������������

Liebherr, sealed single race ball bearing swing

ring, internal teeth

934

944

954

Swing speed

����������������������

0 – 9.4 RPM

0 – 7.9 RPM

0 – 5.6 RPM

stepless

stepless

stepless

Swing torque

����������������������

81.07 kNm

119 kNm

167.23 kNm

Holding brake

���������������������

oil-bath disk brake (negative action)

Option

������������������������������

pedal controlled positioning brake

Operator’s Cab

Cab

���������������������������������

single shell concept with shaped profiles, resil-

iently mounted, sound insulated, tinted windows.

Front window can be folded away under roof,

door with sliding window

Operator’s seat

�������������������

shock absorbing suspension, adjustable to

operator’s weight, 6-way adjustable seat

Controls

����������������������������

integrated into adjustable seat consoles

Monitoring

�������������������������

menu driven digital display of current operating

conditions. Automatic monitoring, display, warn-

ing (audible and visual signal) and saving of

machine malfunction data, such as overheating

of windings, motor bearings, or low hydraulic

oil level

Climate control

�������������������

standard climate control system, combined

cooler/heater, additional dust filter in the outside/

fresh air circuit

Noise emission

2000/14/EC

934

944

954

L

WA

(surround noise)

�������

101 dB(A)

103 dB(A)

105 dB(A)

Undercarriage

Version HR

Drive

��������������������������������

Liebherr swash plate motors with integrated

brake valves on both sides

Transmission

����������������������

Liebherr planetary reduction gears

934

944

954

Travel speed

����������������������

2.6 km/h

2.6 km/h

2.5 km/h

Drawbar pull max.

����������������

318 kN

363 kN

397 kN

Track components

���������������

maintenance-

maintenance-

maintenance-

free

free

free

B 60

D 7 G

D 8 K

Track rollers/Carrier rollers

�����

9/2

13/3

13/3

Tracks

������������������������������

sealed and greased

Track pads

������������������������

triple grouser

Digging locks

���������������������

wet multi-discs (spring applied, pressure

released)

Brake valves

����������������������

integrated into travel motor