Lrh_bildprospekt_en_26032010 12, Electronic evaluation – Liebherr LRH 600 User Manual

Page 12

12

job site:

machine ID:

start date:

stop time:

start time:

duration:

05.11.2008

12:16:48

12:48:48

00:32:00

16383sz.mt

115507

CFA drilling

pile number:

maximum depth:

total concrete vol.:

concrete volume pile:

overconsumption:

maximum incline:

E02

2227 cm

15,123 m³

14,531 m³

29,8 %

0,4 °

tim e

12:45

12:40

12:35

12:30

12:25

12:20

de

p

th

[

c

m

]

2.200

2.000

1.800

1.600

1.400

1.200

1.000

800

600

400

200

0

co

nc

. pr

es

s.

[b

ar

]

5

4,5

4

3,5

3

2,5

2

1,5

1

0,5

0

de

pt

h

[

m

]

20

15

10

5

0

drill pre ss . [bar] v

300

200

100

0

crow d force [kN] v

1

0

drill progr. [r/m ] v

10

8

6

4

2

0

crow d s pe ed [m /m in] v

4

3

2

1

0

re v. spe ed [r/m in] v

25

20

15

10

5

0

de

pt

h

[

m

]

20

15

10

5

0

pile radius [cm ]

60

40

20

0

20

40

60

conc. pre ss . [bar] ^

5

4

3

2

1

0

crow d s pe ed [m /m in] ^

2

1

0

re v. spe ed [r/m in] ^

1

0

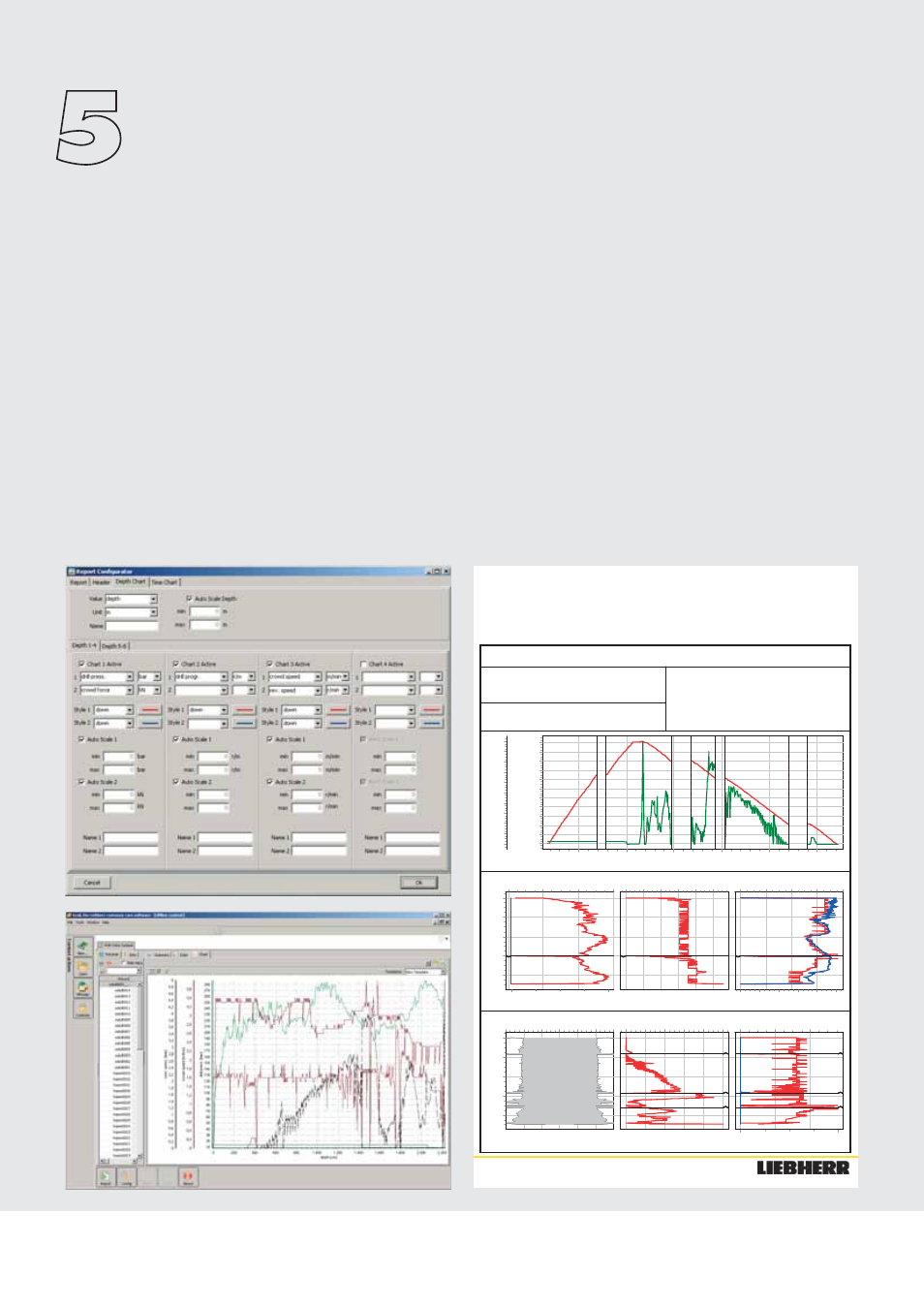

Electronic

Evaluation

Quality assurance through process data recording (PDE)

The process data is constantly measured during the working process. External sensors can also be connected

to the system. Measurement data relevant to the working process is displayed on the monitor in the cabin. The

operator can then control all processes and, if necessary, correct them. The data is stored by the system and can

be transferred to a computer using a CompactFlash-Card.

Evaluation and visualisation through process data reporting (PDR)

The Liebherr software for process data reporting allows to further process the data on a PC, where they are directly

stored, sorted and visualised. Thus, customer-specific evaluations can easily and quickly be created.

5