General information, Nozzle assembly maintenance – Beckett SDC 24 VDC User Manual

Page 4

4

Table 1. Combustion Head Firing Rates

Firing Rate GPH

(min - max)

Head

1.75 - 3.25

F22/F220

2.50 - 5.50

F310

Section: General Information & Nozzle Assembly Maintenance

Adequate Voltage Required

A low or erratic power supply could result in impaired

burner operation, severe delayed ignition or an

explosion inside the heat exchanger resulting in a

burn and/or asphyxiation hazard.

The Model SDC requires a continuous supply of 21.8 to

28 volts DC measured at the burner during operation with

a minimum supply & circuit capacity of 15A. See page 3

for maximum capacity and voltage specifi cations.

An automotive or small engine charging system that is

capable of supplying the required continuous voltage/

amperage is recommended with certain road equipment,

such as asphalt hot patchers and similar applications.

This is especially true while maintaining nominal load

temperatures during idle periods.

Once the burner is set-up at a specifi c voltage, a voltage

regulator shall be used to maintain that voltage within

+/- 1 Vdc during burner operation.

y

y

y

y

Adequate Combustion

and Ventilation Air Supply

Required

Failure to provide adequate air supply could seriously

affect the burner performance and result in damage to

the equipment, asphyxiation, explosion or fi re hazards.

The burner cannot properly burn the fuel if it is not

supplied with a reliable combustion air source.

Follow the guidelines in the latest editions of the NFPA

31 and CSA-B139 regarding providing adequate air

for combustion and ventilation.

y

y

General Information

Refer to the Troubleshooting section of this manual when

experiencing a possible fault condition.

A. Equipment Located in Confi ned Space

The confi ned space should have two permanent openings:

one near the top of the enclosure and one near the

bottom of the enclosure. Each opening shall have a free

area of not less then one square inch per 1,000 BTU’s

per hour of the total input rating of all equipment within

the enclosure. The openings shall have free access to the

building interior, which should have adequate infi ltration

from the outside.

B. Exhaust Fans and Other Air-Using Devices.

Size air openings large enough to allow for all air using

devices in addition to the minimum area required for

combustion air. If there is any possibility of the equipment

room developing negative pressure (because of exhaust

fans, for example), either pipe combustion directly to the

burner or provide a sealed enclosure for the burner and

provide it with its own combustion air supply.

C. Clearances to Burner and Equipment

Provide space around burner and equipment for easy

service and maintenance. Check minimum clearances

against those shown by the equipment manufacturer and

by applicable codes.

D. Exhausting Hazardous Fumes

See warning on this page. Also be conscious of any fumes

produced by the materials that are being heated. Always

ensure adequate ventilation to exhaust all fumes.

Nozzle Assembly

Maintenance

A. Replace the Burner Nozzle.

If applicable, remove the plastic plug protecting the

nozzle adapter threads.

Place a 3/4” open-end wrench on the nozzle adapter.

Insert the nozzle into the adapter and fi nger tighten.

Finish tightening with a 5/8” open-end wrench.

1.

2.

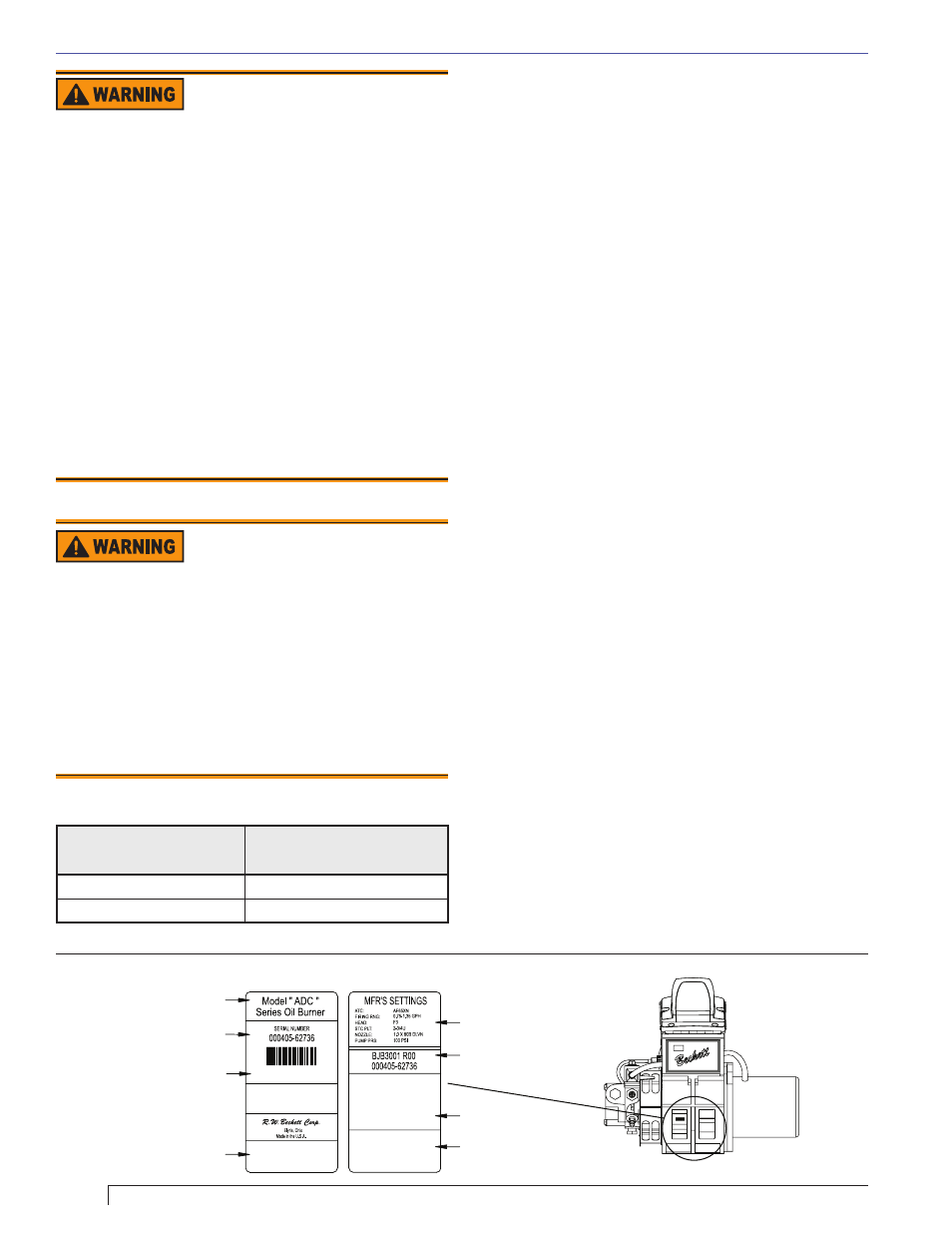

Figure 1. Typical Burner Nameplate

SK10090

PUMP PRS:

100 PSI

Made in the U.S.A.

Elyria, Ohio

R.W.Beckett Corp.

000405-62736

BJB3001 R00

Model " AFG "

SERIAL NUMBER

000405-62736

Series Oil Burner

MFR'S SETTINGS

F3

HEAD:

STC PLT:

NOZZLE:

FIRING RNG:

ATC:

0.75-1.35 GPH

1.0 X 80B DLVN

2-3/4U

AF65XN

RWB

ELYRIA

OHIO U.S.A.

General Model Information

Serial Number

Including Date Code

Rating Information

Primary Group

and Fuel Oil

R.W. Beckett

Manufacturer’s Settings

R.W. Beckett Specification

Number and Revision

Can Be Customized by

Individual Specification

State & Local Approvals