Bosch 1752 User Manual

Page 9

-9-

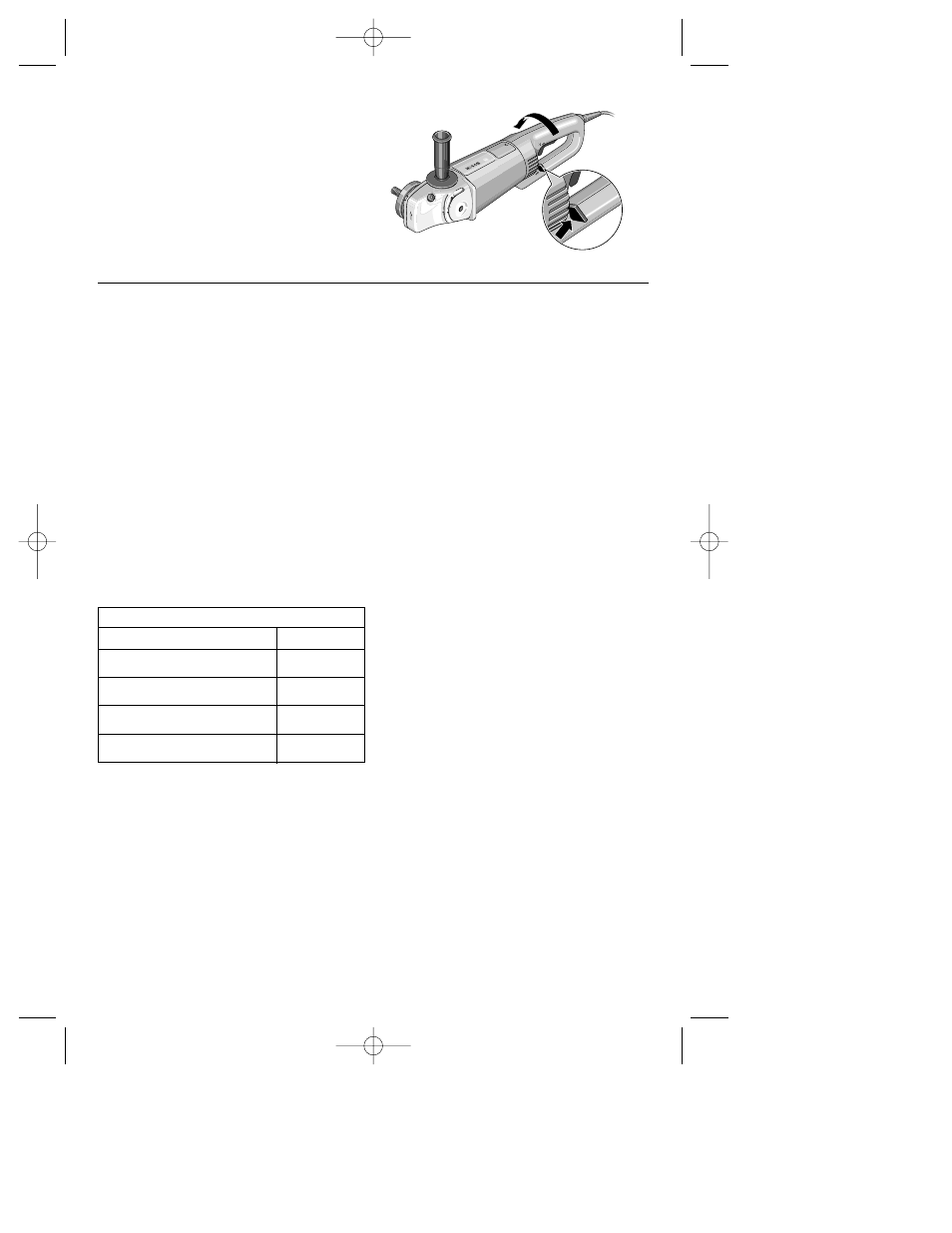

MOTOR HOUSING RELEASE LEVER

(1754 ONLY)

Your tool is equipped with a motor housing

release lever that will allow you to rotate the

spindle in either direction 90˚. To use this

feature, pull release lever in direction of

arrow to release housing, and rotate housing

until it clicks into place.

Sanding Operations

SELECTING SANDING DISC

Sanding discs are made of extremely hard

and sharp aluminum oxide grits, phenol-

resin bonded to a sturdy fiber backing for

fast heavy-duty service and long life. The

discs vary as to size and spacing of the

abrasive grits. OPEN COAT (type H) — used

for soft materials and on paint or varnish.

CLOSED COAT (type K) —used for metal,

hardwood, stone, marble and other

materials.

Sanding discs range in grit from 16 (very

coarse) to 180 (very fine). To obtain best

results, select sanding discs carefully. Many

jobs require the use of several grit sizes and

at times both “open coat and closed coat”

discs are required to get the job done faster.

See chart for application examples.

Operation: Refinishing painted wood or metal surfaces.

REMARKS

GRIT

To remove paint and to smooth

Coarse

surface irregularities.

16-24-30

To smooth

Medium

the rough sanding.

36-50-80

To remove scratches left by

Fine

previous discs.

100-120

To smooth surfaces for painting,

Very Fine

polishing or waxing.

150-180

SANDING TIPS

For best results, tilt the Disc Sander at a 10°

to 15° angle while sanding so that only about

1" of the surface around the edge of the disc

contacts the work.

If the disc (accessory) is held flat or the back

edge of the disc comes in contact with the

work, a violent thrust to the side may result.

If sander is tilted too much, sanding action

will be too great and a rough cut surface or

gouging and snagging will result.

Guide the Disc Sander with crosswise

strokes. Be careful not to hold the sander in

one spot too long. Do not use a circular

motion, as this makes swirl marks. Test

before use on scrap stock.

Do not force or apply pressure when

sanding. Use only the weight of the tool for

pressure. Excess pressure actually slows the

tool down. If faster stock removal is desired,

change to a coarser grit disc.

Remove gummy paint from metal with an

“open coat” disc. Sand until sparks start to

appear, then stop and change to a “closed

coat” disc to remove any remaining paint.

SANDING WOOD

When sanding wood the direction of the disc

motion at the contact point should parallel

the grain as much as possible. The rapid cut

of discs and the swirl type scratch pattern

they occasionally create generally prohibit

their use for producing the final finish.

Scratches and circular marks are usually the

result of using too coarse a grit. When

changing to a finer grit, move across the

sanding lines that were made by a previous

coarser disc.

SANDING METAL

When sanding automobiles or appliances,

wipe the metal clean with a non-flammable

solvent or commercial cleaner to remove all

wax and grease. By doing this first, the

sanding discs will sand better and last

longer.

For heavy duty work, use a coarse grit disc

first. Follow-up with a medium grit to remove

scratches. To produce smooth finish, use

fine grit disc.

BM 1609929A20 3/03 3/12/03 10:35 AM Page 9