Using the miter gauge, Miter gauge auxiliary facing – Bosch 4100DG User Manual

Page 64

64.

Using The Miter Gauge

CROSSCUTTING, MITER CUTTING, BEVEL CUTTING, COM-

POUND MITER CUTTING and when RABBETING across the end

of a narrow workpiece, the MITER GAUGE is used.

For your own safety, always observe the following

safety precautions in addition to the safety

instructions on Pages 2, 3, 4 & 5.

Never make these cuts freehand (without using the miter gauge or

other auxiliary devices) because the blade could bind in the cut and

cause a KICKBACK or cause your fingers or hand to slip into the

blade.

Always lock the miter gauge securely when in use.

Remove rip fence from table during any operations which utilize the

miter gauge.

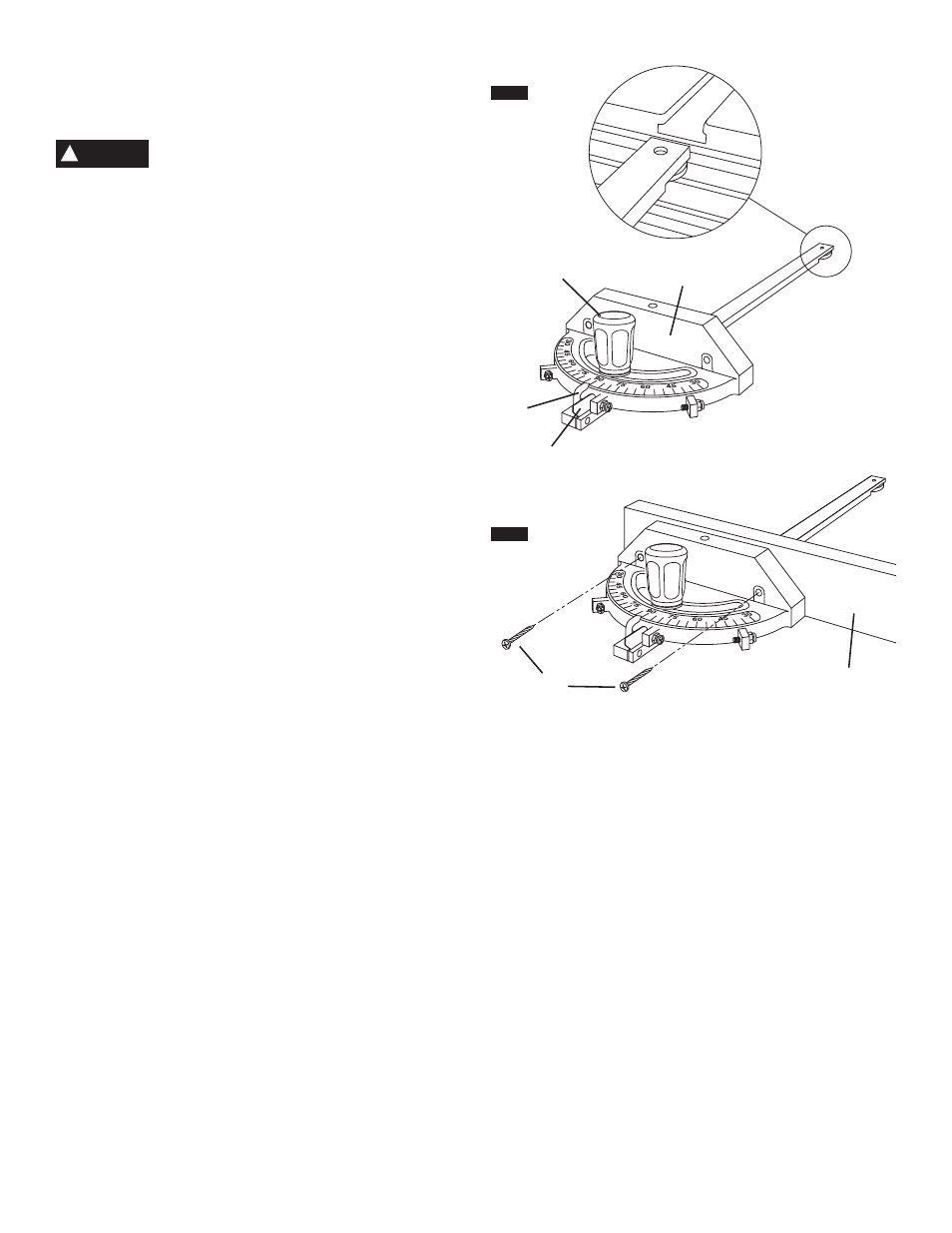

The miter includes a “T” groove disk

1 for easy insertion into table

groove and quicker removal from the table (Fig 54).

When cross cutting and the blade set at 90º or 45º to the table, the

miter gauge can be used in either slot on the table. When cross

cutting and the blade is tilted, use slot on right side of table where

the blade is tilted away from your hands and miter gauge.

To adjust the miter angle:

Loosen lock knob

1 and set the miter gauge body 2 so the pointer

3 is at desired angle, then tighten lock knob 1 (Fig. 54).

The miter gauge body

2 will stop at 90º and both right and left 45º.

To rotate the miter gauge body

2 beyond these points, the stop

plate

4 must be flipped out of the way.

Miter Gauge Auxiliary Facing

A template for drilling holes in the miter gauge is provided on page

84, which allows you to attach an AUXILIARY FACING

5 to provide

additional support to cut longer pieces. Select a suitable piece of

smooth straight wood, drill two holes through it and attach it with

screws

6 (Fig. 55).

Example:

A. Drill 1/4" dia. holes thru miter gauge.

B. Drill 5/32" dia. holes thru (board 3/4" thick, 3" high, and desired

length).

C. Attach with two No. 12 round head wood screws 1-1/2" long,

6,

not included (Fig. 55).

Be sure screws never protrude above outside surface of facing.

Be sure facing does not interfere with the proper operation of the

saw blade guard.

NOTE: When bevel crosscutting, attach facing so that it extends to

the right of the miter gauge and use the miter gauge in the groove

to the right of the blade.

WARNING

!

FIG. 55

FIG. 54

5

1

3

2

4

6