Figure 1.5a: gas burner connection – Bryan Boilers Forced Draft Steam Boilers User Manual

Page 5

1.5 GAS SUPPLY CONNECTION - FORCED DRAFT UNITS

The installation must conform completely to the

requirements of the authority having jurisdiction,

or in the absence of such, requirements shall

conform in the U.S. to the current National Fuel

Gas Code, ANSI Z223.1-1984, or in Canada to

the current Installation Code for Gas Burning

Appliances and Equipment (CAN/CGA B149.1-

M91), or Oil Burning Equipment (CSA B139-

M91), and applicable regional regulations for the

class; which should be followed carefully in all

cases.

Drip leg must be installed on gas supply piping.

Consult the local gas utility company for

inspection and authorization of all gas supply

piping and flue connections.

The regulator vent line must be vented to outside

of building on any boiler equipment with electric

gas pilot ignition.

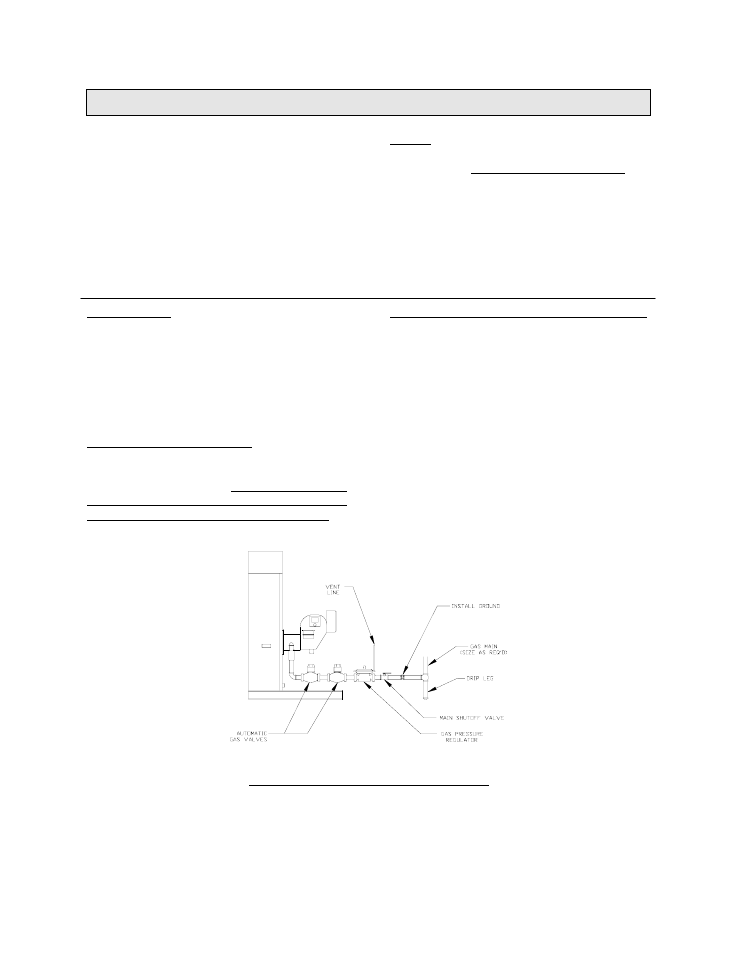

1.5.1 DRIP LEG

A drip leg or sediment trap must be installed in

the gas supply line. See Fig. 1.5A. The gas line

must be connected to a supply main at least as

large as the gas train connection at the boiler.

This connection should be made with a union so

that the boiler gas train components and burner

may be easily removed, if necessary, for service.

1.5.2 GAS PIPING LEAK TEST

After completion of the gas piping hookup, the

installation must be checked for leaks, using a

soap and water solution. Disconnect the boiler

and gas train from the gas supply piping during

any pressure testing of the gas supply system.

1.5.3 VENTING OF GAS TRAIN COMPONENTS

Gas pressure regulator - The regulator must be

vented to the outside air, using minimum 1/4"

tubing or pipe. The vent line should terminate in a

downward direction to be free of restriction.

Diaphragm gas valves (V48A or V88A) - The vent

line off of these gas valves must be vented to

outdoors, the same as the regulator.

Normally open vent valves - These valves must

be piped to outdoors using pipe no smaller than

that of the valve.

Gas pressure switches - Vent these switches to

outdoors using a minimum of 1/4" tubing or

piping.

FIGURE 1.5A: GAS BURNER CONNECTION

NOTE: USE PIPE COMPOUND, WHICH IS RESISTANT TO THE ACTION OF LIQUID PETROLEUM

GAS. DO NOT USE TEFLON TAPE.