Engine components, Technical information, General information – Briggs & Stratton VANGUARD 610000 User Manual

Page 3: Tune-up specifications, Safety specifications

GB

GB

1

Note: (This note applies only to engines used in the U.S.A.) Maintenance, replacement or repair of the emission control devices and systems may be performed

by any nonroad engine repair establishment or individual. However, to obtain no charge repairs under the terms and provisions of the Briggs & Stratton

warranty statement, any service or emission control part repair or replacement must be performed by a factory authorized dealer.

ENGINE COMPONENTS

Fig. 1

1

Choke Control (if equipped)

2

Breather/Breather tube

3

Spark Plug (2 locations)

4

Engine Model Label

Model xxxxxx Type xxxxxx Code xxxxxxxx

5

Oil Pressure Sensor

6

Oil Filter

7

Oil Drain Plug (2 locations)

8

Rotating Screen

9

Cover − Carburetor

10

Carburetor or LPG/NG Mixer

11

Mechanical Fuel Pump

12

Air

Cleaner

13

Oil Fill

14

Dipstick

15

Regulator/Rectifier

16

Starter Solenoid

17

Starter

18

Exhaust

System/Muffler

19

Throttle control (2 locations)

Record your engine Model, Type and Code numbers here

for future use.

Record your date of purchase here for future use.

TECHNICAL INFORMATION

Engine Power Rating Information

The gross power rating for individual gas engine models is

labeled in accordance with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & Torque

Rating Procedure), and rating performance has been

obtained and corrected in accordance with SAE J1995

(Revision 2002-05). Torque values are derived at 3060

RPM; horsepower values are derived at 3600 RPM. Actual

gross engine power will be lower and is affected by, among

other things, ambient operating conditions and engine-to-en-

gine variability. Given both the wide array of products on

which engines are placed and the variety of environmental

issues applicable to operating the equipment, the gas

engine will not develop the rated gross power when used in

a given piece of power equipment (actual on-site" or net

power). This difference is due to a variety of factors

including, but not limited to, accessories (air cleaner,

exhaust, charging, cooling, carburetor, fuel pump, etc.),

application limitations, ambient operating conditions

(temperature, humidity, altitude), and engine-to-engine

variability. Due to manufacturing and capacity limitations,

Briggs & Stratton may substitute an engine of higher rated

power for this Series engine.

GENERAL INFORMATION

This is a twin cylinder, overhead valve (OHV), air-cooled

engine. It is a low emissions engine.

In the state of California, Model 540000 and 610000

engines are certified by the California Air Resources Board

to meet emissions standards for 1000 hours. Such

certification does not grant the purchaser, owner or

operator of this engine any additional warranties with

respect to the performance or operational life of this

engine. This engine is warranted solely according to the

product and emissions warranties stated elsewhere in this

manual.

Model 540000

Bore

85.5 mm (3.36 in.)

. . . . . . . . . . . . . . . . . . . . . . .

Stroke

78 mm (3.07 in.)

. . . . . . . . . . . . . . . . . . . . . . .

Displacement

895 cc (54.6 cu. in.)

. . . . . . . . . . . . . . .

Model 610000

Bore

85.5 mm (3.36 in.)

. . . . . . . . . . . . . . . . . . . . . . .

Stroke

86.5 mm (3.04 in.)

. . . . . . . . . . . . . . . . . . . . .

Displacement

993 cc (60.6 cu. in.)

. . . . . . . . . . . . . . .

Note:

For practical operation, the horsepower loading

should not exceed 85% of rated horsepower. Engine power will

decrease 3-1/2% for each 1,000 feet (300 meters) above sea

level and 1% for each 10

° F (5.6° C) above 77° F (25° C).

Engine will operate satisfactorily at an angle up to 25

°.

TUNE-UP SPECIFICATIONS

Armature air gap

0.13 − 0.20 mm (0.005 − 0.008 in.)

. . .

Spark plug gap

0.76 mm (0.030 in.)

. . . . . . . . . . . . . . .

Valve clearance with valve springs installed and piston 6 mm

(1/4 in.) past top dead center (check when engine is cold).

Intake

0.10 − 0.15 mm (0.004 − 0.006 in.)

. . . . . . . . . . .

Exhaust

0.10 − 0.15 mm (0.004 − 0.006 in.)

. . . . . . . . .

SAFETY SPECIFICATIONS

• Read entire Operating & Maintenance Instructions

AND the instructions for the equipment this engine

powers.*

• Failure to follow instructions could result in serious

injury or death.

BEFORE OPERATING

ENGINE

* Briggs & Stratton does not necessarily know what equip-

ment this engine will power. For that reason, you should

carefully read and understand the operating instructions

for the equipment on which your engine is placed.

• Make you aware of hazards associated with engines

• Inform you of the risk of injury associated with those

hazards, and

• Tell you how to avoid or reduce the risk of injury.

THE OPERATING & MAINTENANCE

INSTRUCTIONS CONTAIN SAFETY

INFORMATION TO:

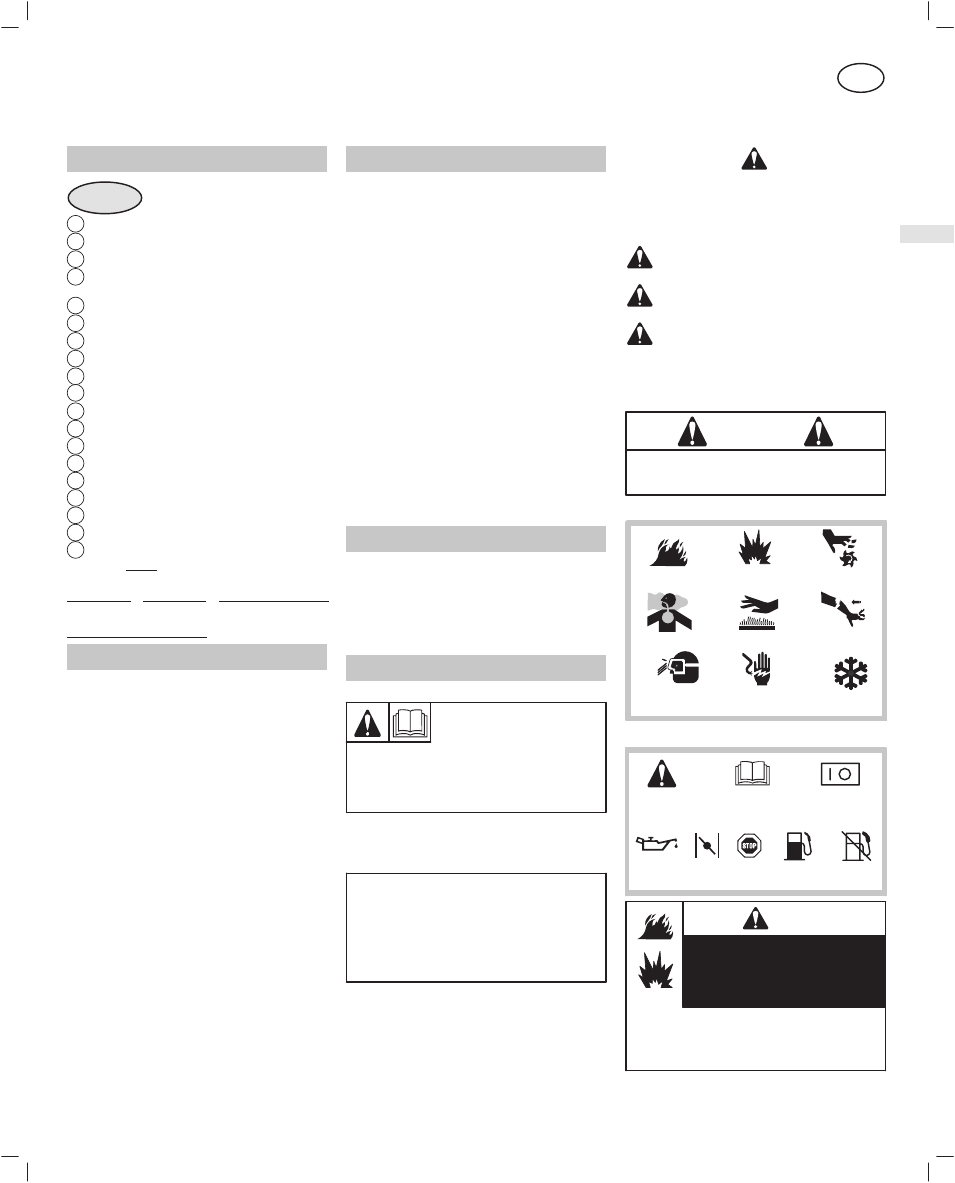

The safety alert symbol

(

)

is used to identify safety

information about hazards that can result in personal injury.

A signal word (DANGER, WARNING, or CAUTION) is

used with the alert symbol to indicate the likelihood and the

potential severity of injury. In addition, a hazard symbol

may be used to represent the type of hazard.

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION

,

when used without the alert symbol,

indicates a situation that could result in damage to

the engine.

The engine exhaust from this product contains chemi-

cals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

WARNING

Hazard Symbols and Meanings

Explosion

Toxic Fumes

Shock

Hot Surface

Kickback

Fire

Moving Parts

Frostbite

Wear Eye Protection

International Hazard Symbols and Meanings

Stop

Fuel Shutoff

Read Operator’s

Manual

Fuel

Choke

Safety Alert

Oil

On Off

Starting engine creates sparking.

Sparking can ignite nearby flammable

gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area, do not

start engine.

• Do not use pressurized starting fluids because

vapors are flammable.

WARNING