Bryant 597C User Manual

Page 2

B.

Inspect Equipment

File claim with shipping company prior to installation if shipment

is damaged or incomplete. Locate unit-rating plate on unit-corner

panel. It contains information needed to properly install unit.

Check rating plate to be sure unit matches job specifications.

II.

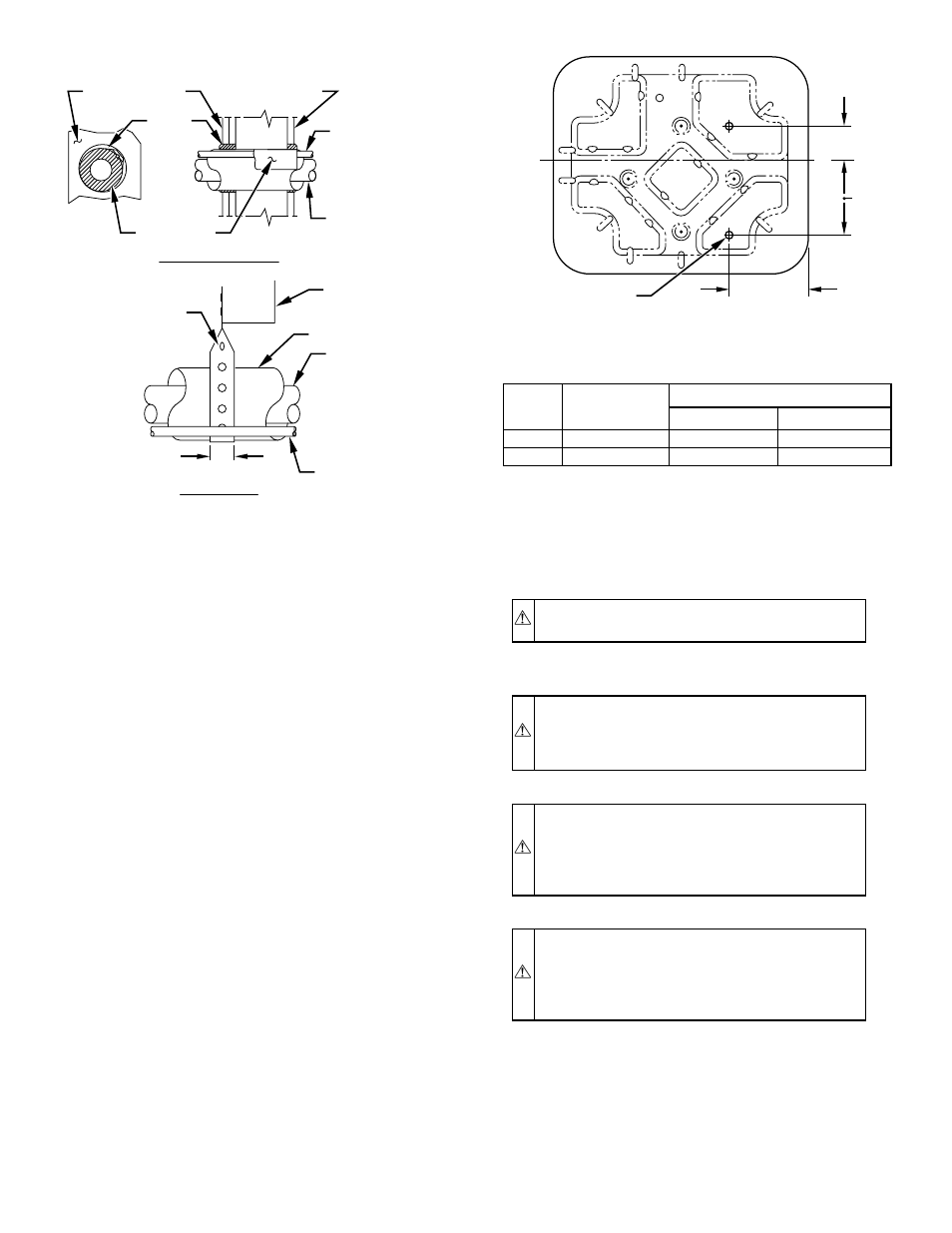

INSTALL ON A SOLID, LEVEL MOUNTING PAD

If conditions or local codes require the unit be attached to pad,

tie-down bolts should be used and fastened through knockouts

provided in unit base pan. Refer to unit-mounting pattern in Fig. 3

to determine base-pan size and knockout-hole location.

On rooftop applications, mount on level platform or frame. Place

unit above a load-bearing wall and isolate unit and tubing set from

structure. Arrange supporting members to adequately support unit

and minimize transmission of vibration to building. Consult local

codes governing rooftop applications.

Roof-mounted units exposed to winds above 5 mph may require

wind baffles to achieve adequate defrost. Consult Low-Ambient

Guideline for wind-baffle construction.

NOTE:

Unit must be level to within ± 2° (± 3/8 in./ft) per

compressor manufacturer specifications.

III.

CLEARANCE REQUIREMENTS

When installing, allow sufficient space for airflow clearance,

wiring, refrigerant piping, and service. Allow 30-in. clearance to

service end of unit and 48 in. above unit. For proper airflow, a 6-in.

clearance on 1 side of unit and 12 in. on all remaining sides must

be maintained. Maintain a distance of 24 in. between units.

Position so water, snow, or ice from roof or eaves cannot fall

directly on unit.

On rooftop applications, locate unit at least 6 in. above roof

surface.

IV.

OPERATING AMBIENTS

The minimum outdoor-operating ambient in cooling mode is 55°F,

and the maximum outdoor-operating ambient in cooling mode is

125°F.

V.

CHECK INDOOR CHECK-FLO-RATER™ PISTON

Check indoor-coil piston to see if it matches the required piston

shown on outdoor unit-rating plate. If it does not match, replace

indoor-coil piston with piston shipped with outdoor unit. The

piston shipped with outdoor unit is correct for any approved

indoor-coil combination.

CAUTION:

Remove indoor-coil piston if unit is to be

installed on system with a TXV-metering device.

VI.

MAKE PIPING CONNECTIONS

WARNING:

Relieve pressure and recover all refrigerant

before system repair or final unit disposal to avoid

personal injury or death. Use all service ports and open all

flow-control devices, including solenoid valves.

CAUTION:

If ANY refrigerant tubing is buried, pro-

vide a 6-in. vertical rise at service valve. Refrigerant-

tubing lengths up to 36 in. may be buried without further

consideration. For lengths above 36 in., consult your local

distributor.

CAUTION:

To prevent damage to unit or service valves

observe the following:

•Use a brazing shield.

•Wrap service valves with wet cloth or use a heat sink

material.

Outdoor units may be connected to indoor unit using accessory-

tubing package or field-supplied refrigerant-grade tubing of cor-

rect size and condition. For tubing requirements beyond 50 ft,

substantial capacity and performance losses can occur. Following

the recommendations in the Residential Split-System Long-Line

Application Guideline will reduce these losses. Refer to Table 1

for field-tubing equivalent-line length. Refer to Table 2 for

accessory requirements.

Fig. 2—Connecting Tubing Installation

A94028

INSULATION

VAPOR TUBE

LIQUID TUBE

OUTDOOR WALL

INDOOR WALL

LIQUID TUBE

VAPOR TUBE

INSULATION

CAULK

Avoid contact between tubing and structure

NOTE:

THROUGH THE WALL

HANGER STRAP

(AROUND VAPOR

TUBE ONLY)

JOIST

1

″

MIN.

SUSPENSION

Fig. 3—Mounting Unit to Pad

DIMENSIONS (IN.)

UNIT

SIZE

MINIMUM

MOUNTING-PAD

DIMENSIONS

TIEDOWN KNOCKOUT LOCATIONS

A

B

018

20 x 27

4–1/8

7–1/8

024–060

26 x 32

5–1/16

9-11/16

A97375

B

A

L

C

8

3

⁄

16

″

3

⁄

8

IN. DIA TIEDOWN

KNOCKOUTS

(2) PLACES

IN BASEPAN

—2—