Troubleshooting, adjustment, & service, Traction drive belt adjustment – Briggs & Stratton FB13250BS User Manual

Page 20

19

Troubleshooting, Adjustment, & Service

A

D

B

1/8” Max.

C

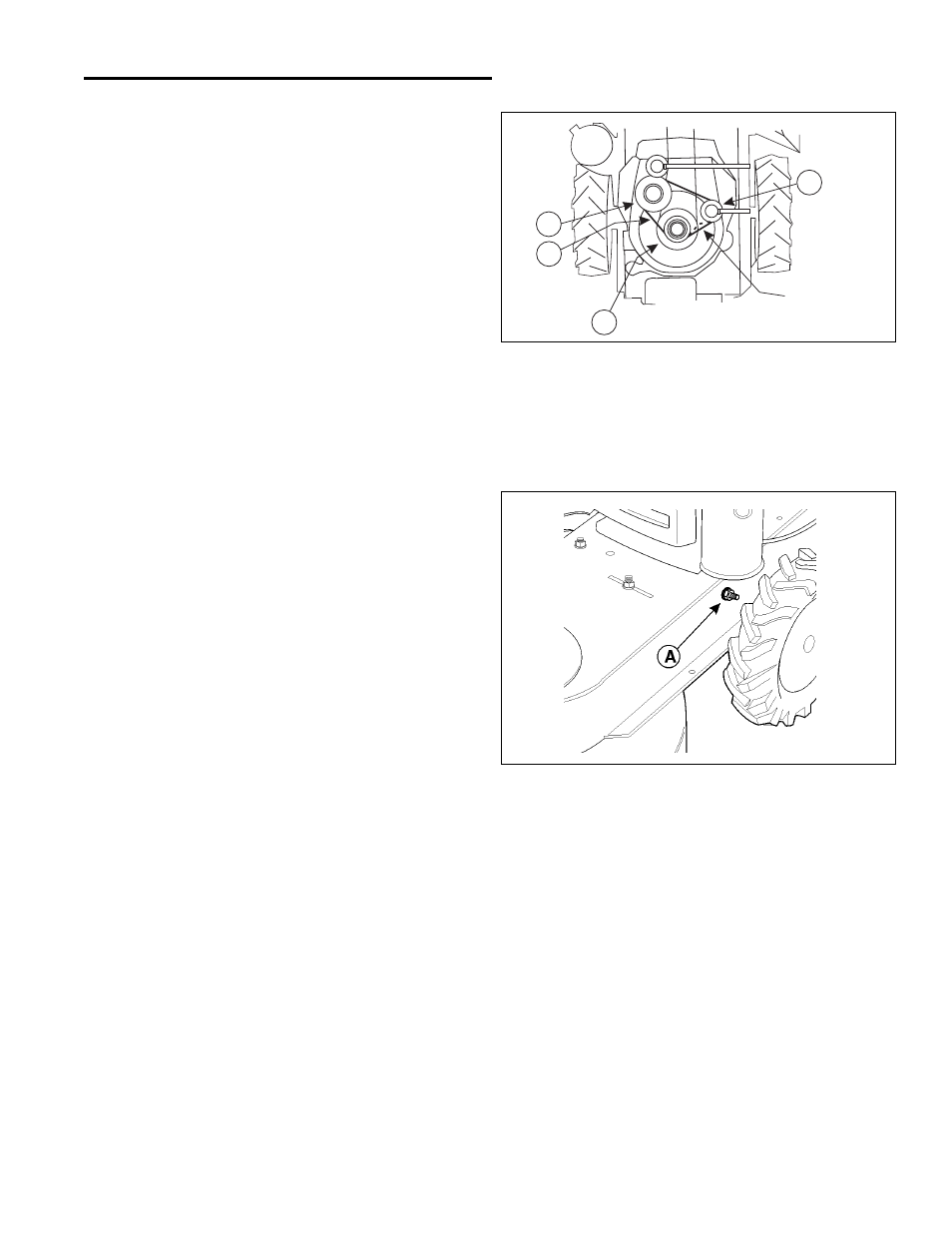

Figure 21 - Traction Drive Belt Adjustment

A. Transmission Pulley

B. Drive Belt

C. Engine Pulley

D. Idler Pulley

Figure 22 - Traction Drive Belt Adjustment

A. Adjustment Nut

TRACTION DRIVE BELT

ADJUSTMENT

If the mower drive is not functioning properly, the drive

belt may need to be adjusted;

For S/N 0 - 071601075

The traction drive belt tension is adjusted by a bolt and

screw system. To adjust belt tension:

1. Loosen traction drive idler pulley lock nut (D, Figure

19).

2. Loosen or tighten traction drive idler pulley adjust-

ment nut (E, Figure 19) as required. Belt deflection

should be approximately 1/8" halfway between the

engine pulley (C, Figure 21) and idler pulley (D) with

10 lbs. of pressure on the belt.

3. Tighten idler pulley lock nut.

4. Test mower and repeat adjustment as required.

For S/N 071601076 - up

The traction drive belt tension is adjusted through spring

tension. To adjust spring tension:

1. Tighten or loosen nut (A, Figure 22) to achieve prop-

er belt tension. Belt deflection should be approxi-

mately 1/8" halfway between the engine pulley (C,

Figure 21) and idler pulley (D).

2. Tighten adjustment nut of the tension spring until

expanded spring length is 6-3/8" maximum. For mea-

surement purposes, the spring can be reached

through the access pan beneath the engine.