American Dryer Corp. AD-840 User Manual

Page 42

39

Telephone: (508) 678-9000

Fax: (508) 678-9447

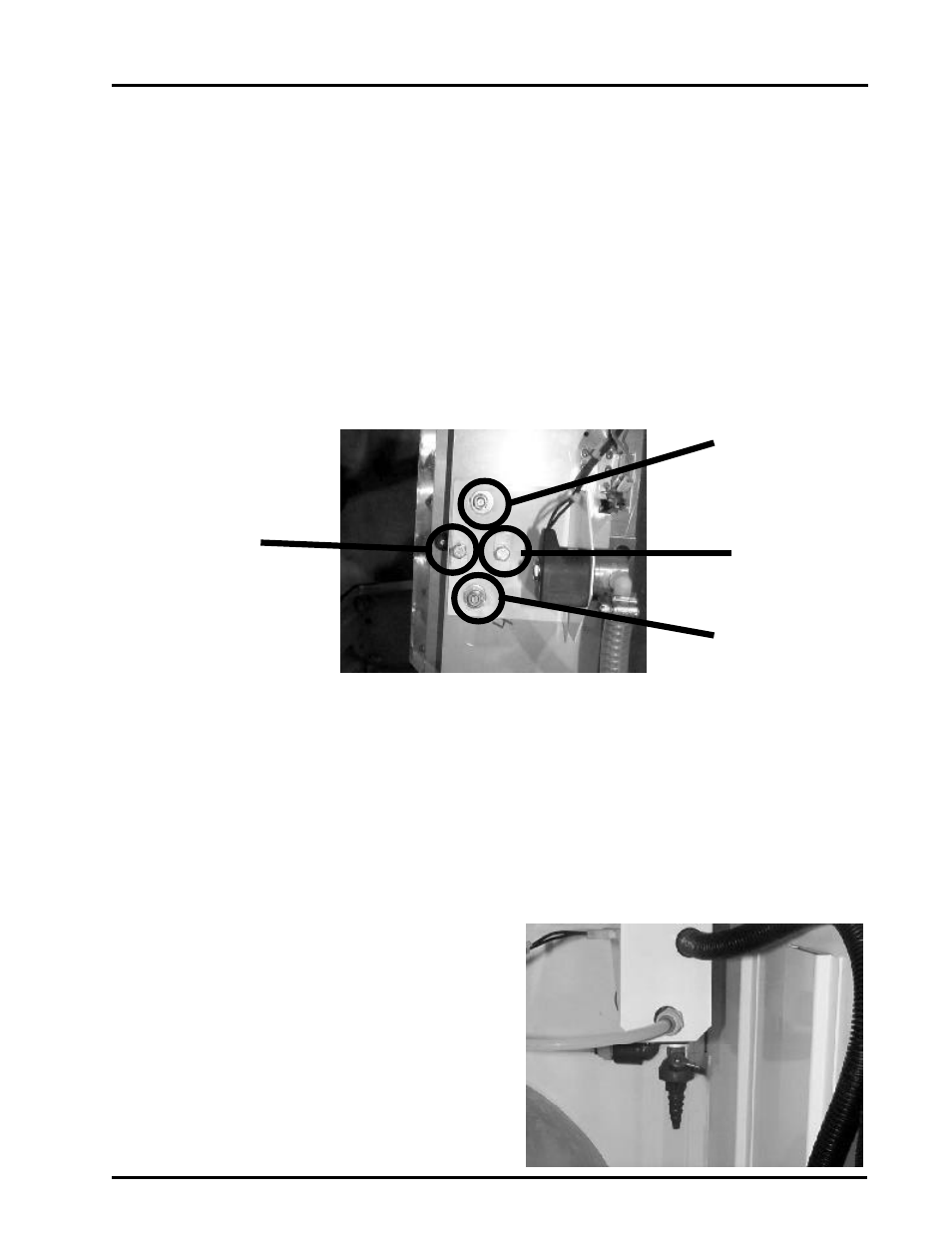

B. VENDING NOZZLE ADJUSTMENT

Dispensing nozzle can be adjusted to direct water into the center of the bay. Nozzles come from the

factory already adjusted. If flow is severely off center, it may indicate the machine is not level. Check

machine before adjusting nozzles.

1. Determine from the front of the machine which way the nozzle is aiming at. Let’s say it is too far

right and forward.

2. Open vending machine computer door and stand behind it. Facing the nozzle adjustment bolts,

loosen the left and right mounting bolts (diagram 23). Tap solenoid mounting bracket to YOUR

LEFT to correct a flow too far to the right and vice versa. (when looking at flow from front of door)

3. Front and read adjustments are corrected by loosening and tightening the front and rear bolts.

Loosen the lock nuts on the adjusting bolts. If flow is too far forward, loosen the bolt FARTHER

FROM YOU. If bolt is already at the end of its adjustment, then tighten the other bolt. Tighten left

sand right mounting bolts before checking flow. Tighten lock nuts when adjustment is completed.

C. TUBING AND FITTING REPLACEMENT TECHNIQUE

There are two types of tubing attachment methods used on this vending machine. One is the push-in

type and the other is the plastic clamp type.

PUSH-IN TYPE:

To remove a push-in tubing, push ring on fitting and

pull on tubing. (diagram 24 on next page)

To reattach, firmly push tubing back into fitting. If

tubing-fitting joint leaks because of frequent re-

moval, cut 1/2” off the tubing and reattach.

front adjust

left & right

adjust

left & right

adjust

rear adjust

diagram 23

diagram 24