AMF High Speed Bun Divider User Manual

High speed bun divider

HIGH SPEED BUN DIVIDER

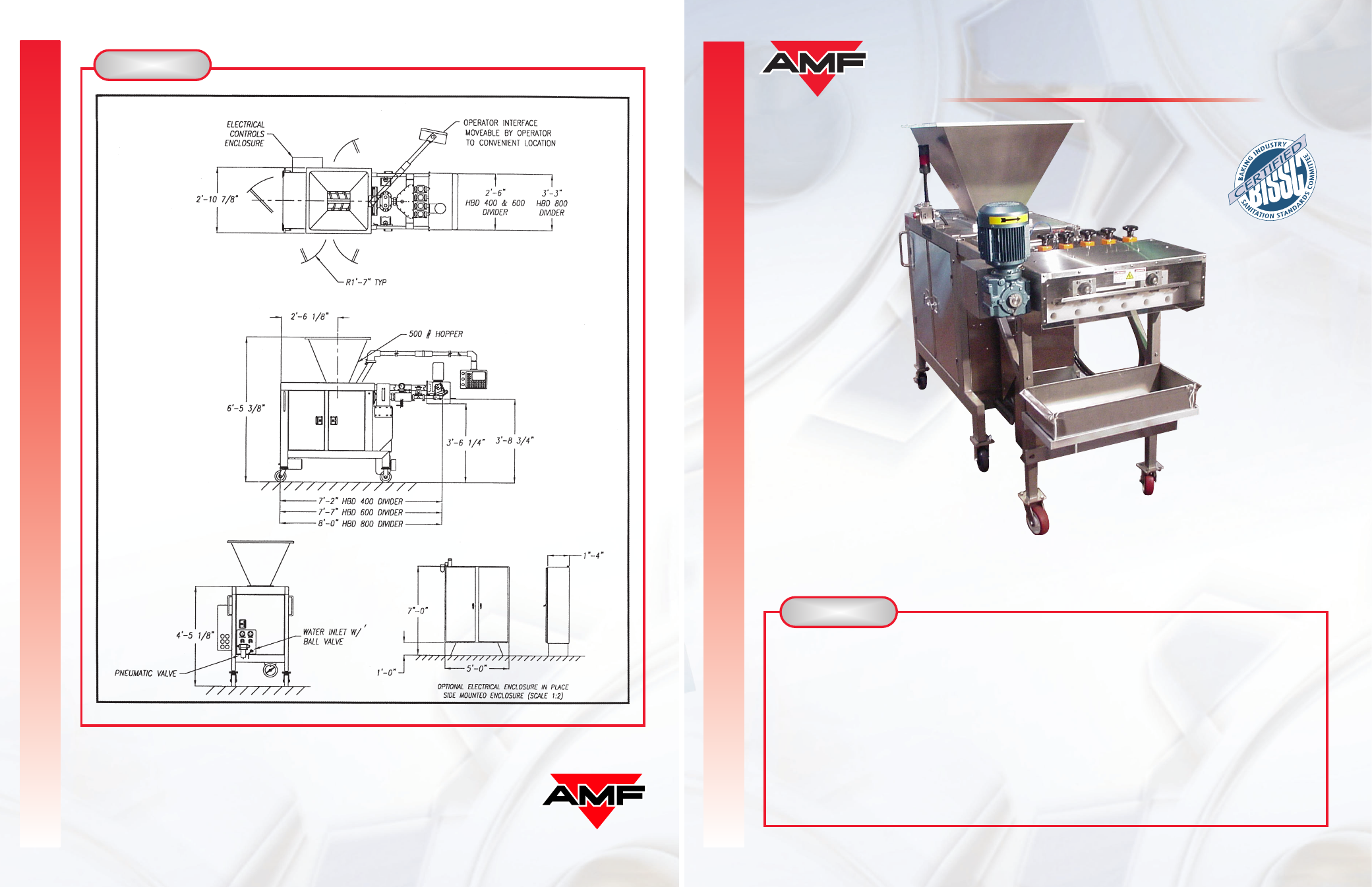

Dimensional

Drawing

For more information please call

your Account Manager or

1-800-BAKERS-1.

Headquarters

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771 or 804-355-7961

FAX: 1-804-342-9724

www.amfbakery.com

European operation

West Park Ring Road

Leeds LS16 6QQ England

Tel.: 1132-787110

Fax: 1132-741415

06/2001

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

HIGH SPEED BUN

DIVIDER

Most Accurate Scaling available through advanced

extrusion technology

•

Increased product yield

•

Reduced waste

•

Improved product uniformity

•

Consistent scaling accuracy over the life of the

divider - 15 years or more*

Reduced Operating Cost

•

No divider oil required with the HBD, which reduces

operating and sanitation cost

•

Efficient design with few moving parts for reduced

maintenance cost

•

Rotary drive design provides a service life 3-4 times

that of conventional dividers

• Extrusion Divider Designed for High Speed Bun Production

• Most Accurate Scaling Available

Increased Productivity and Flexibility

•

Increased operating speeds up to 135 cuts per

minute can increase your hourly production yield

•

Long, continuous runs for days at a time without

downtime for cleaning or maintenance adjustments

can increase profits per unit

Improved Automation

•

Operator interface-based recipe management system

is provided for automated divider setup

•

Electronic synchronization system is tied into the

Pan-O-Mat, allowing the HBD recipe management

system to automate the setup of the Pan-O-Mat as

well

Features &

Benefits

Printed in

Canada