AMF Ultra S User Manual

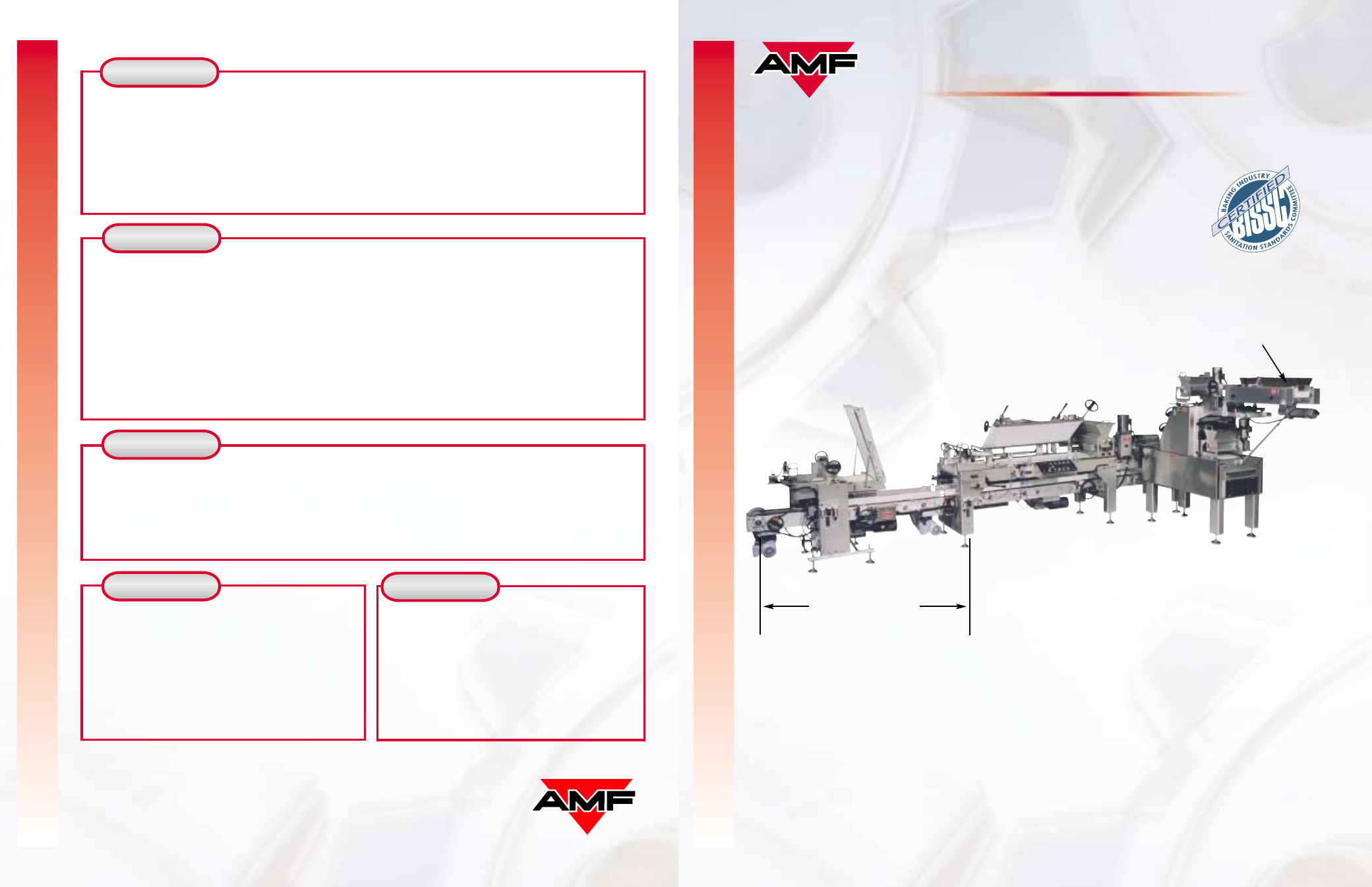

Sheeter/moulder/panner, Ultra ‘’s’’ cross grain

For more information please call

your Account Manager or

1-800-BAKERS-1.

Headquarters

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771 or 804-355-7961

FAX: 1-804-342-9724

www.amfbakery.com

European operation

West Park Ring Road

Leeds LS16 6QQ England

Tel.: 1132-787110

Fax: 1132-741415

08/2002

22-N-AB

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

Moulder / Panner

section

•

Easily removable endless transfer belt 18'' wide.

•

Delrin transfer plate and stainless steel adjustable plow.

•

Stainless steel adjustable curling mat.

•

D.C. variable speed, removable stainless steel rotary flour

sifter with automatic cut-off.

•

Fixed speed easily removable endless moulder belt 20'' wide

(cantilever frame design).

•

Easily removable endless “motorized” pressure board belt

19'' wide. (Adjustable at both ends, with floating action).

•

New design “insert style” U.H.M.W. dough guides, supplied

with 4 different thicknesses (1/2'', 3/4'', 1'', 1-1/4'').

•

Stainless steel Sanigrid drop chain assembly (15'' wide X 22''

long) with manual adjustable dough guides.

•

Double loaf detection device.

•

Two-position discharge (straight or angle drop) to adapt

“optional” hand twist table section.

•

Stainless steel sliding catch pan.

•

Manual adjustable pan guides (min. 7'' - max. 19'').

•

A.C. variable speed dual strand plastic table-top pan

conveyor.

•

Magnetic pan indexer (belt type) with soft start drive system

and SLC 5/03 processor (Elev. 21-3/4'' ± 1'').

•

Complete Moulder/Panner section is all timing belt driven

(without chains and sprockets).

ULTRA ‘’S’’ CROSS GRAIN

•

Stainless steel type 304 frame (sanitary design).

•

Special slanted infeed conveyor with Teflon® coated dough

guides and adjustable flattener roller (Elev. 61'' ± 1'').

•

Easily removable endless infeed belt 12'' wide.

•

D.C. variable speed, removable stainless steel rotary flour

sifters with automatic cut-off.

•

Fixed speed 17'' wide, adjustable sheeting rolls driven

by a 1-1/2 H.P. motor (top front sheeting roll is grooved).

•

Baked Teflon® coated sheeting roll scrapers.

•

A.C. variable speed, easily removable endless sheeter belt

14'' wide, driven by a 3/4 H.P. motor (Elev. 39-1/4'' ± 1'').

•

Lexan® guard over sheeting rolls with safety switches.

•

Stainless steel sliding catch pan.

•

Adjustable legs.

•

Stainless steel side covers with safety sensors.

•

U.H.M.W. sheeter belt scraper with stainless steel catch pan.

•

Complete Sheeter sector is all timing belt driven

(without chains and sprockets).

•

AMF dough spacer with D.C. controls.

•

Third set of sheeting rollers with independent drive.

•

Extra stainless steel Sanigrid drop chains:

• 12-1/2'' x 22'' LG • 11'' x 22'' LG • 9-1/2'' x 22'' LG

•

Pressure board equipped with new air operated lifting device.

•

A.C. inverters on the following:

- Dough spacer

- Flour sifters

- Sheeter rolls

- Transfer belt

- Moulder make-up belt

•

AMF hand twisting table with magnetic pan indexer.

Sheeter Section

Electrical

Specifications

Options

•

Nema 4 remote control panel with the following:

- Allen Bradley starters

- D.C. controls for flour dusters

- A.C. inverters (2) for sheeter belt and pan conveyor

- Allen Bradley SLC 5/03 processor

- Main disconnect switch

- Relays, terminal block, wiring

•

Nema 4 operator panel mounted to moulder frame with the

following:

- Allen Bradley push-buttons and alarm message display

- Potentiometers for flour sifters, sheeter belt and pan

conveyor

- Safeties

- Emergency stop

- Red Lion display to indicate fault messages.

•

CAD electrical wiring.

•

Solid stainless steel construction.

•

Magnetic pan indexer (belt type) with soft start drive system.

•

Table/flattener roll and multiple roller drop gate assemblies.

•

Belt type loading section from AMF Moulder/Panner:

belt conveyor is raised vertically while hand twister is not in

use, in order to permit operator to see the actual panning

operation, and correct a possible “double”.

•

Added safeties and guards.

•

Electrical control panel.

Options Hand

Twisting section

ULTRA ‘’S’’

CROSS GRAIN

SHEETER/MOULDER/PANNER

• 110 loaves/minute 18 to 24 oz.

• Pan size up to 19’’ wide

• Reliable performance

Shown with optional

Dough Spacer

Shown with optional

Handtwist Table