Straight line, Sheeter/moulder/panner, Straight line sheeter/moulder/panner – AMF Straight Line Sheeter Moulder Panner User Manual

Page 3

SPECIAL DESIGN FEATURES

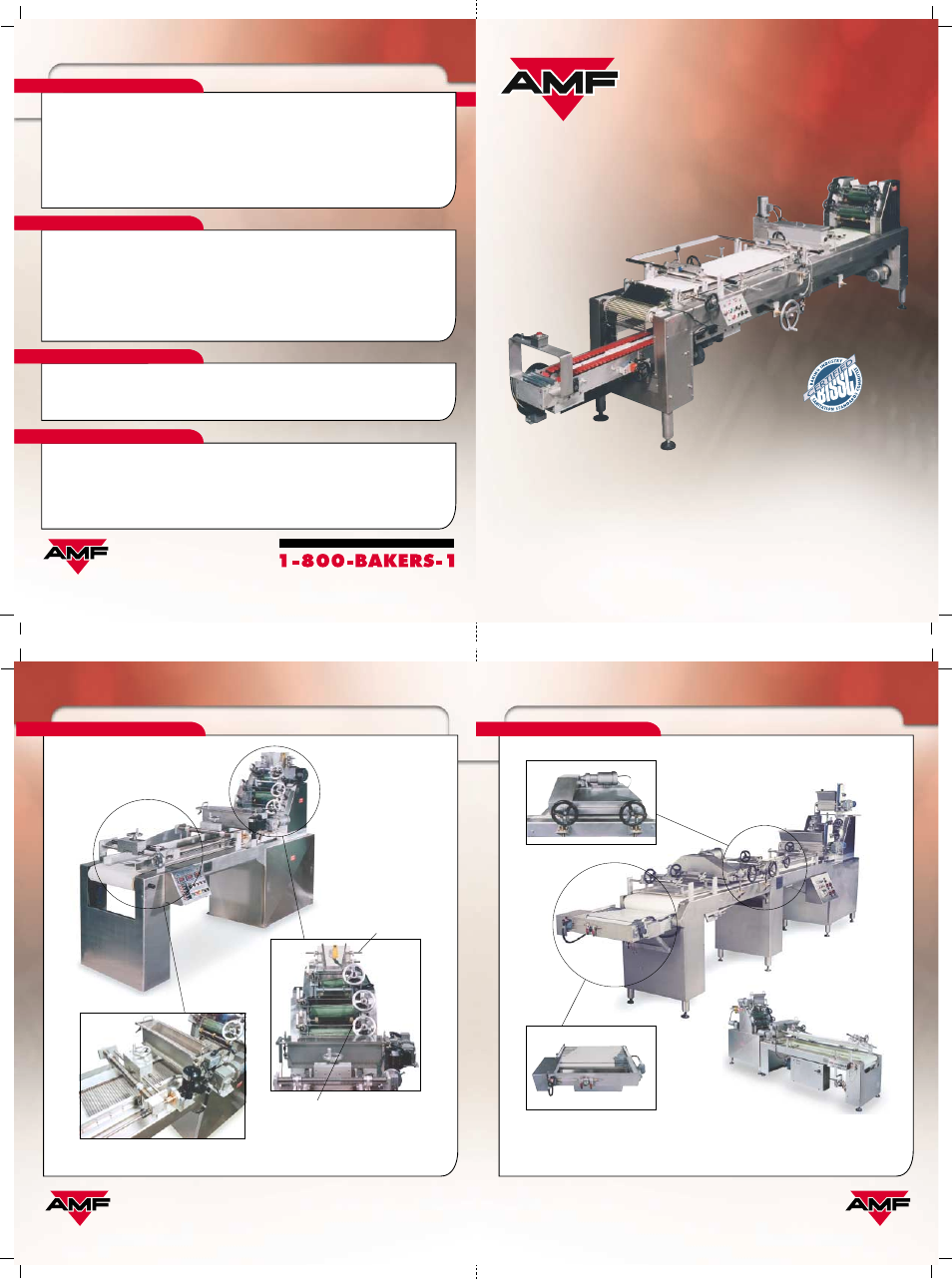

STRAIGHT LINE

SHEETER/MOULDER/PANNER

• For frozen dough and specialty breads

• 6 oz. to 36 oz. and 6’’ to 18’’ dough piece length

• All stainless steel construction

• Equipment meets OSHA requirements

• Working range: 6 oz. to 36 oz., 6 in. to 18 in. length

STRAIGHT LINE

SHEETER/MOULDER/PANNER

STRAIGHT LINE SHEETER/MOULDER/PANNER

SPECIAL DESIGN FEATURES

STRAIGHT LINE SHEETER/MOULDER/PANNER

STRAIGHT LINE SHEETER/MOULDER/PANNER

HEADQUARTERS

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771

or 804-355-7961

FAX : 1-804-342-9724

EUROPEAN OPERATION

West Park Ring Road

Leeds LS16 6QQ England

Tel. : 1132-787110

Fax : 1132-741415

[email protected]

www.amfbakery.com

FOR MORE INFORMATION PLEASE CALL YOUR ACCOUNT MANAGER OR

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

06/2001

22-N-AD

Printed in Canada

MECHANICAL SPECIFICATIONS

ELECTRICAL SPECIFICATIONS

MOULDER SECTION

OPTIONS

‘’MOULDER OPTION’’

Above shown

with removable

style pressure

board adjustable

on both ends.

“HOPPER”

Construction Lexan®

adjustable dough guide

Above shown with motorized dough guide

adjustment with digital readout.

Shown with:

•

3 sets of sheeting rolls (10" wide)

•

Driven by motor/reducer 3/4 H.P.

Stretcher section. Full stainless

steel construction. Easy access to

all components, fully adjustable

height permitting maximum

desired product length.

(Motor 1/2 H.P.)

Special diverter with aligner and pneu-

matically operated drop gate. Aluminum

and stainless steel construction. This unit

transports and facilitates smooth transfer

of dough pieces onto desired position of

freezer belt.

Above shown with:

•

pressure board belt with a pneumatically

operated lifting device for sanitation purposes

(motorized or not motorized) or fix pressure board

•

special extended length pressure board (80")

•

Special slanted infeed conveyor with Teflon® coated

dough guides and adjustable flattener roller

(elev.61"

±

1")

.

•

D.C. variable speed, removable stainless steel

rotary flour sifters with automatic cut-off.

•

Sheeting rolls (17" wide) adjustable.

•

Top sheeting roll is grooved to prevent

dough hesitation.

•

Sheeting rolls driven by a 2 H.P. motor.

- Top: 320 RPM

- Bottom: 400 RPM

•

Sheeter belt (14" wide) SP93F Polytek endless.

- Mechanical variable speed

- Elevation 38"

±

1"

•

Sheeting roll guard (Lexan®) with safety switches.

•

Stainless steel removable panels with safety switches.

•

Adjustable legs.

•

Stainless steel sliding catch pan.

•

Sheeter head with timing belt (optional).

•

Nema remote control mounted under

Moulder frame with the following:

- Allen Bradley starters

- D.C. controls for flour sifters (2)

- Allen Bradley SLC 5/03 processor

- Main disconnect switch

- Relays, terminal block, wiring

•

Nema 4 operator panel mounted

to Moulder frame with the following:

- Allen Bradley push-buttons and alarm

message display

- Potentiometers for flour sifters, sheeter belt

- Safeties

- Emergency stop

- Red Lion display to indicate fault messages

•

CAD electrical drawings

•

A.C. inverter on the following:

- Sheeter rolls

- Sheeter belt

- Flour sifters (2)

•

24'' wide F.D.A. approved synthetic moulding belt.

•

Adjustable stainless steel curling mat.

•

D.C.variable speed, removable stainless steel

rotary flour sifter.

•

Removable style pressure board (8'' wide X 80'' long)

adjustable on both ends.

•

U.H.M.W. side guides with stainless steel backing.

•

Stainless steel catch pan.

MOULDER

•

Removable style pressure boards:

Note: “Special” widths and lengths available

upon request.

•

Motorized dough guides adjustment with

digital readout.

•

Pneumatically operated pressure board lifting device.

•

Stainless steel Dough Stretcher with 2nd pressure board.

•

Product Diverter switch and aligner.

SHEETER

•

New dough spacer (larger).

•

Third set of sheeting rollers for high speed performance

or specialty doughs.

4

1

1

2

2

4

3

3