Service and adjustments, Tiller – Ariens 90102800 User Manual

Page 14

14

TILLER

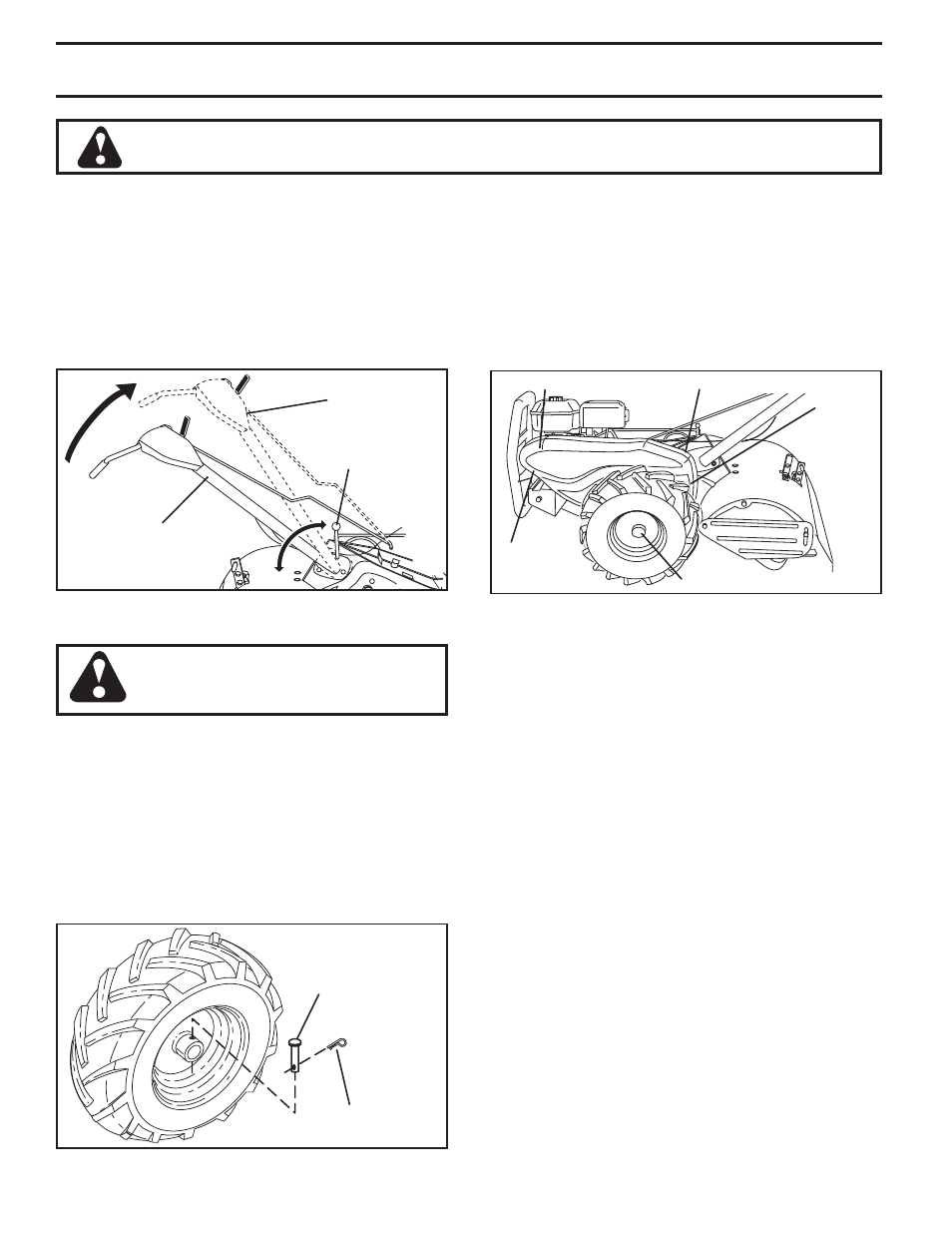

TO ADJUST HANDLE HEIGHT (See Fig. 23)

Select handle height best suited for your tilling conditions.

Handle height will be different when tiller digs into soil.

• First loosen handle lock lever.

•

Handle can be positioned at different settings between

“HIGH” and “LOW” positions.

• Retighten handle lock lever securely after adjusting.

Fig. 23

Fig. 24

Fig. 25

TO REMOVE BELT GUARD (See Fig. 25)

NOTE: For ease of removal, remove hairpin clip and

clevis pin from left wheel. Pull wheel out from tiller about

1 inch.

• Remove two (2) screws from side of belt guard.

•

Remove hex nut and washer from bottom of belt guard

(located behind wheel).

• Pull belt guard out and away from unit.

• Replace belt guard by reversing above procedure.

TIRE CARE

CAUTION: When mounting tires, un-

less beads are seated, over in fla tion

can cause an explosion.

• Maintain 20 pounds of tire pressure. If tire pressures

are not equal, tiller will pull to one side.

• Keep tires free of gasoline or oil which can damage

rubber.

TO REMOVE WHEEL (See Fig. 24)

• Place blocks under trans mis sion to keep tiller from

tipping.

• Remove hairpin clip and clevis pin from wheel.

• Remove wheel and tire.

• Repair tire and reassemble.

CLEVIS PIN

HAIRPIN CLIP

CAUTION: Disconnect spark plug wire from spark plug and place wire where it cannot come into

contact with plug.

SCREW

AND

WASHER

HEX NUT

AND

WASHER

(LOCATED

BEHIND

TIRE)

SCREW AND WASHER

BELT GUARD

HAIRPIN CLIP AND CLEVIS PIN

TO REPLACE GROUND DRIVE BELT

(See Figs. 25 and 26)

• Remove belt guard as described in “TO REMOVE

BELT GUARD”.

•

Remove old belt by slipping off engine pulley first then

remove from transmission pulley.

• Place new belt in groove of transmission pulley and

into engine pulley. BELT MUST BE IN GROOVE ON

TOP OF IDLER PULLEY. NOTE POSITION OF BELT

TO GUIDES.

• Check belt adjustment as described below.

• Replace belt guard.

• Reposition wheel and replace clevis pin and hairpin

clip.

GROUND DRIVE BELT ADJUSTMENT

(See Fig. 26)

For proper belt tension, the extension spring should have

about 5/8 inch (16 mm) stretch when Tine control are in

“EN GAGED” position. This tension can be attained as

fol lows:

• Loosen cable clip screw securing the drive control

cable.

• Slide cable forward for less tension and rearward for

more tension until about 5/8 inch (16 mm) stretch is

obtained while the Tine control are engaged.

• Tighten cable clip screw securely.

SERVICE AND ADJUSTMENTS

HANDLE

(LOW POSITION)

HANDLE LOCK

LEVER

HANDLE

(HIGH POSITION)