Wiring diagram – FMI CL1 User Manual

Page 7

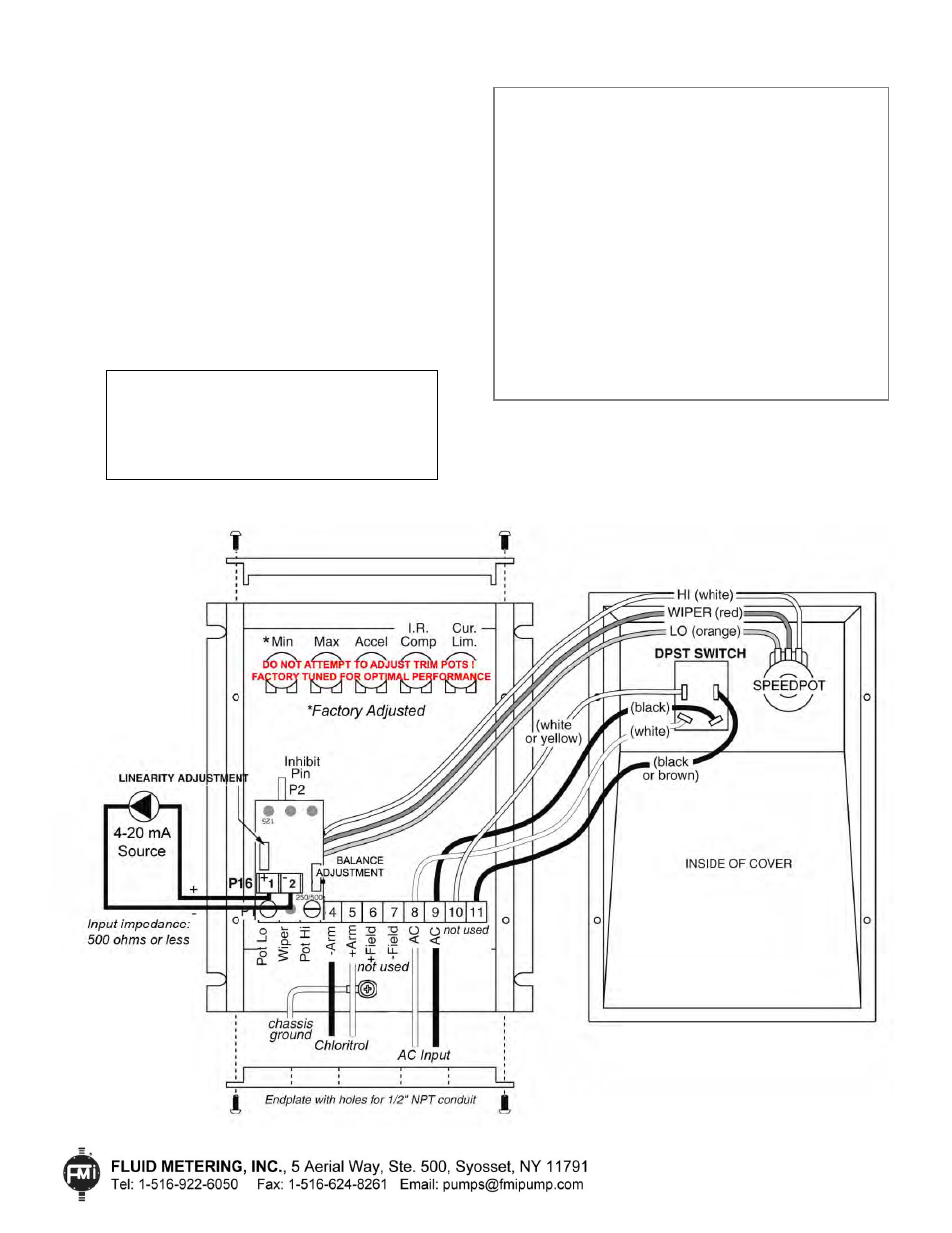

WIRING NOTES:

1. Size all wires that carry drive motor or line current to

handle currents as specified by national state, and/or

local codes. All other wires may be #18 AWG or

smaller as permitted by local code.

2. Separate control wires from all DC Drive and AC line

wires when routed in conduits or in wire trays. There

are two (2) threaded 1/2” NPT holes in one endplate,

located near the terminal strip, for this purpose.

3. The C100A is provided with a fuse in AC line 1 (P1-11).

This fuse is sized to open in the event of a shorted

drive armature, or if the 0-90 VDC line to the drive

motor is shorted to earth ground. As long as the 120

VAC input is connected properly, there is no additional

fusing required.

Wiring Diagram

Important Note:

Trimpots are factory tuned for

optimal performance. Adjustments in the field

should only be made with the guidance of FMI

support personnel or performed by an authorized

FMI factory representative. Before performing

any trimpot adjustments, contact FMI factory.

WIRING PROCEDURE

1) Remove the four (4) cover screws to remove the

cover and gain access to the terminal strip.

Note: When removing the cover, take care not to

damage the cover gasket or the wires connecting

the cover controls with the main circuit board.

2) If an external 4-20 mA control source is used,

(typically a sensor, analyzer, or PLC etc.),

connect the 4-20 mA output of this device to the

+1 and -2 terminals as shown below.

3) After all wiring is complete, replace the cover.

Take care to align the gasket and torque down

the four (4) cover screws such that the gasket is

evenly compressed and seals properly.

IN-CL-14

3/11/14 HW

Page 7 of 10