Duff-Norton NZ-100 User Manual

Page 7

4-5. Ball Nut Removal

backlash. Push back and forth on the nut,

without rotation. Movement should be no

more than shown in Table 1. Use a dial

indicator if available.

It is not uncommon for nuts to exhibit wear

before any damage to the screw. If this is

the case, a new nut can be fitted without

screw replacement.

Other than the lubrication described in the previous

section, regular maintenance should not be

required. If disassembly is required to repair

damage or a failure, the following procedure may

be followed.

4-1. Disassembly

(Refer to Figure 5-1)

4-2. Screw & Tube Disassembly

4-3. Screw Removal

4-4. Screw and Nut Inspection

SECTION IV

MAINTENANCE

7

Do not disassemble ball nut from

tube unless ball nut inspection or

repair is necessary.

Note

Remove SuperCylinder from installation

and move to a work area.

Remove limit switch (if fitted).

Loosen two setscrews on outer tube.

Unscrew tube and pull off. Clean excess

grease from screw and tube.

Remove the metric socket head screws

holding the trunnion housing to the

gearbox, and separate the housings.

1.

2.

3.

4.

Spread and remove nylon nut guide from

inner end of translating tube.

Loosen two setscrews holding lifting nut.

These are installed with thread locking

adhesive and may require heating.

Clamp lifting nut in vise. Insert bar in clevis

hole and unscrew translating tube.

1.

2.

3.

1.

2.

3.

1.

2.

Remove the two pipe plugs from the

trunnion housing.

Use a long pin punch to drive grooved pin

out of the screw (note direction of groove

taper). Support screw to avoid bearing

damage.

Remove slotted nut and withdraw screw.

Clean excess grease from the screw and

nut. Inspect the screw thread areas for any

wear, pitting, gouges, spalling, brinelling,

or corrosion. Any deterioration of the

thread contact surfaces is cause for

replacement.

If screw is undamaged, clamp it in a vise

with soft jaws and check the nut for

3.

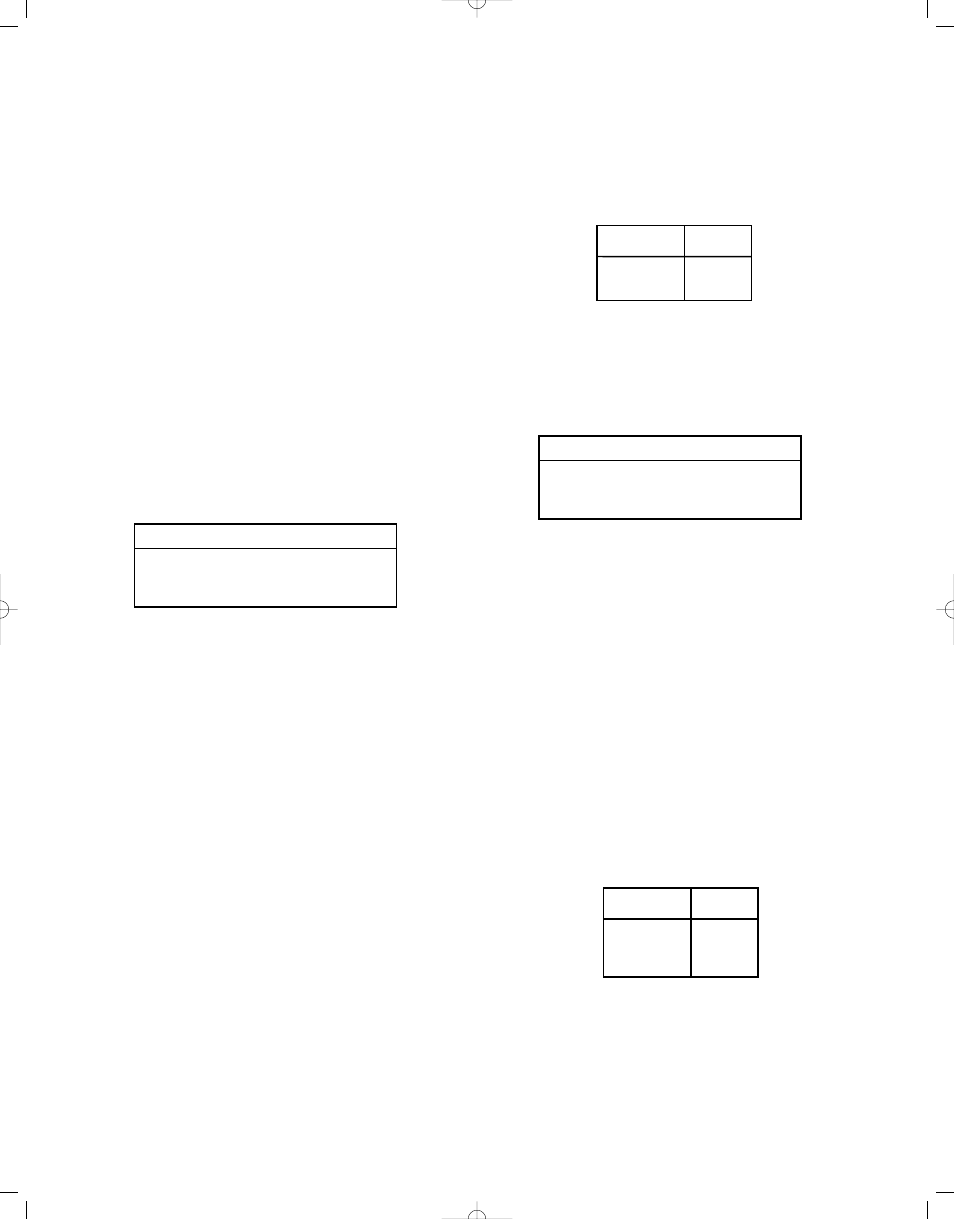

1.0”

.008”

1.17-2.50” .025”

3.0” .050”

Max

Screw O.D Backlash

Table 1

Removal of a ball nut from the screw

is not recommended unless there is a

reason to do so.

Note

Clamp screw in vise with soft jaws and use

an impact wrench to loosen the stop

washer bolt in the end of the screw. This

bolt is installed with high strength locking

adhesive. The use of heat is

recommended.

Ball screw nuts, if already determined to

need replacement, can be screwed off,

with balls being lost as it comes off the

screw.

If ball nuts are to be reused, it is

recommended that an arbor be made for

capturing balls. This will eliminate the need

to reload balls. The arbor can be made

from any stiff material and should be about

2" longer than the ball nut. A piece of

tubular material is easier to secure inside

the nut, but a solid bar can be used. Arbor

diameters are given in Table 2.

Hold arbor tight against and centered with

the end of the screw (a pilot to engage in

the screw hole is helpful). Turn the nut

down the screw and continue running it

over the arbor until it is completely off the

screw.

Use wire, tape, cable ties, or similar to

prevent the arbor from falling through the

nut.

1.

2.

3.

4.

5.

1.17”

.88”

1.5” 1.156”

2.25” 1.88”

3.0” 2.50”

Arbor

Screw O.D Dia.

Table 2