Duff-Norton SK6415-200 (SPA Series AC) User Manual

Page 10

NOTE

If unit has potentiometer assembly (26) and gear (26b) does

not have to be replaced or if unit has no potentiometer

feature, proceed to Step 35.

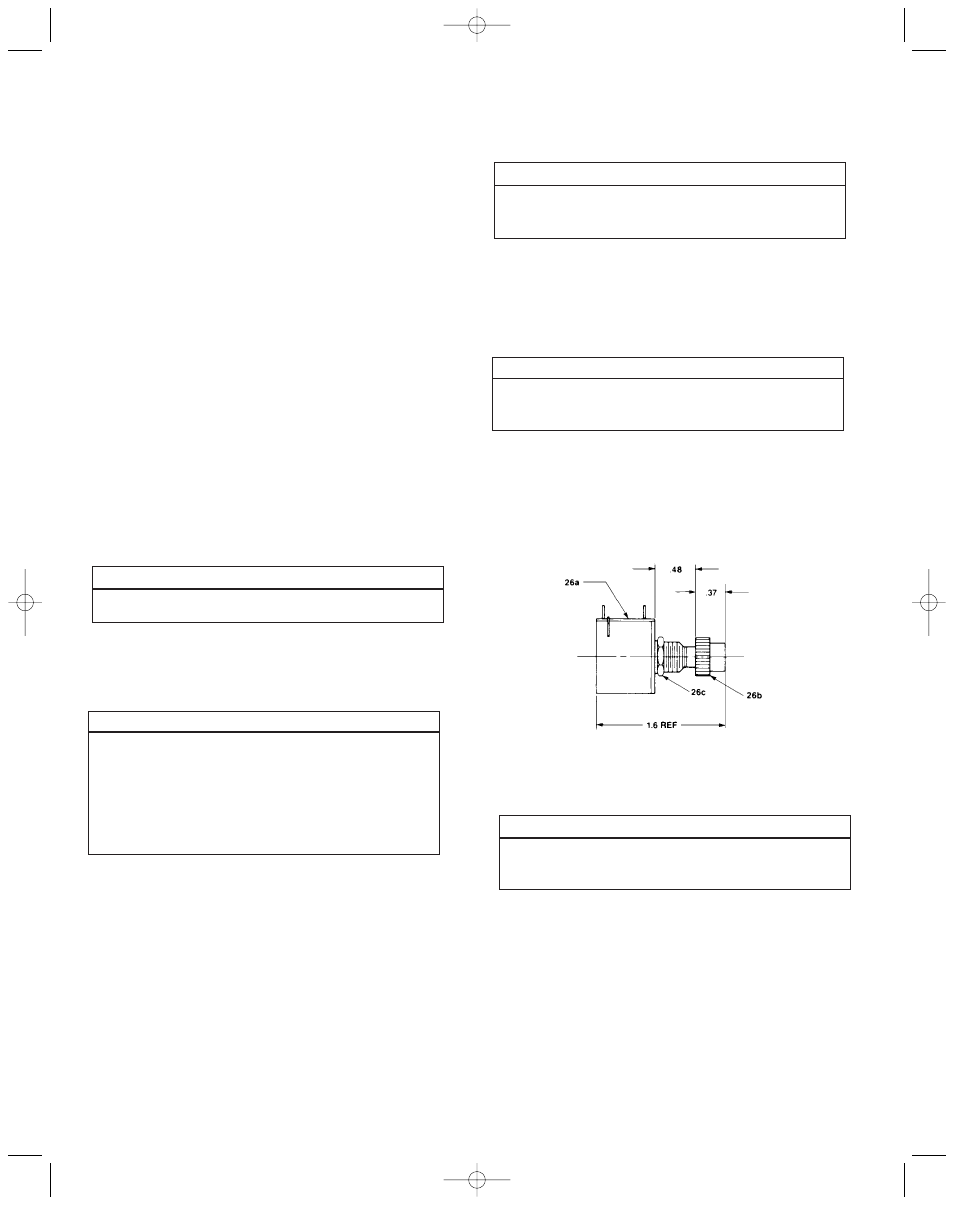

34. Potentiometer Assembly (26)

a. If nut and washer were removed from

potentiometer, assemble washer (26d) and nut

(26c) on potentiometer (26a). Nut (26c) should

not be tightened on potentiometer (26a) face.

b. Assemble gear (26b) on potentiometer (26a)

shaft.

NOTE

Gear should be assembled with a very light press. See

sketch for required dimension of gear on potentiometer. Take

care not to damage potentiometer.

35. Assembly of Cover (9)

a. Feed motor (53) lead wires into capacitor box

cover (9). Care should be taken not to damage

lead wires. Assemble cover on housing (42),

aligning dowel pins (27) with bore in

cover and flats of limit switch shaft (22) with bore

and slot in end of screw (62).

NOTE

Limit switch shaft should be able to spring up when a light

pressure with finger is applied downward on limit switch nut

and removed.

b. Install lock washers (8) and button head cap

screws (7).

c. Feed motor lead wires (red and blue small

terminal ends only) into cover switch box through

5/8” diameter hole. Install terminal of red lead wire

on normally closed terminal of left side of switch.

Install terminal of blue lead wire on normally closed

terminal of right side of switch. (Wires going to

switches should be same color.) It may be necessary

threads).

27. Insert intermediate pinion shaft (32) in housing (42)

and place thrust washer (31) over shaft (32).

Assemble intermediate cluster gear (33) on shaft

and place thrust washer (31) on top.

28. Assemble bearing (28) on input pinion (29) (press on

inner bearing ring to prevent damage to

bearing).

29. Pack housing (42) gear box cavity with Aeroshell #6

grease (no substitutes).

30. Assembly of Motor (53) to Housing (42)

a. Note location of flat on input pinion by

marking spot on the housing. See Figure 6-1B.

b. Insert grommet (50) on input pinion (29)

between coupling (47) posts and install “O”-

Ring (52) in cavity of insert (51).

c. Pack cavity with Aeroshell #6 grease.

d. If hole plug (54) is in rear end of motor,

remove.

e. Feed motor (53) lead wires through hole in

housing (42) lining up couplings (47) on input

pinion (29) and motor (53) shaft. (Alignment is

critical at this point. See Figure 6-1B.)

NOTE

Input pinion (29) and motor (53) shaft flats are opposite

each other.

f. Assemble motor (53) into housing (42) . Before

assembling lock washers (46) and socket head

screws (45), hold motor firmly in place and, with

a screwdriver, turn motor shaft by using

screwdriver slot in end of motor shaft.

NOTE

Before turning motor shaft, make sure pinion shaft has

not been pushed out. It may be necessary to hold pinion

shaft down while turning motor shaft. If couplings are

properly installed, the motor can be turned freely in both

directions. If motor shaft will not turn, this is an

indication that couplings are not properly aligned and

assembly should be corrected.

g. Install lock washers (46) and socket head

screws (45).

31. Insert dowel pins (27) in housing (42) and place

gasket (41) in place over dowel pins (27).

32. Install air vent (58) in outer tube (55) ( it may be

necessary to back outer tube out in order to

install air vent or to have vent in a more

desireable position). Spot drill tube and install

set screw (33) to hold tube in place.

33. Install spring (61) into end of screw (62).

10

6415-200 manual 10/10/06 11:46 AM Page 10