Duff-Norton Ball Screw Rotating User Manual

Page 8

8

long enough to extend 1 1/2˝ to 2˝ beyond

each end of the lifting nut.

Note

Apply tape to arbor O.D. at end away from ball

screw pilot to prevent lifting nut from accidentally

running off of arbor during disassembly (an O-ring

with a large cross section, stretched over the arbor,

is ideal for this purpose.)

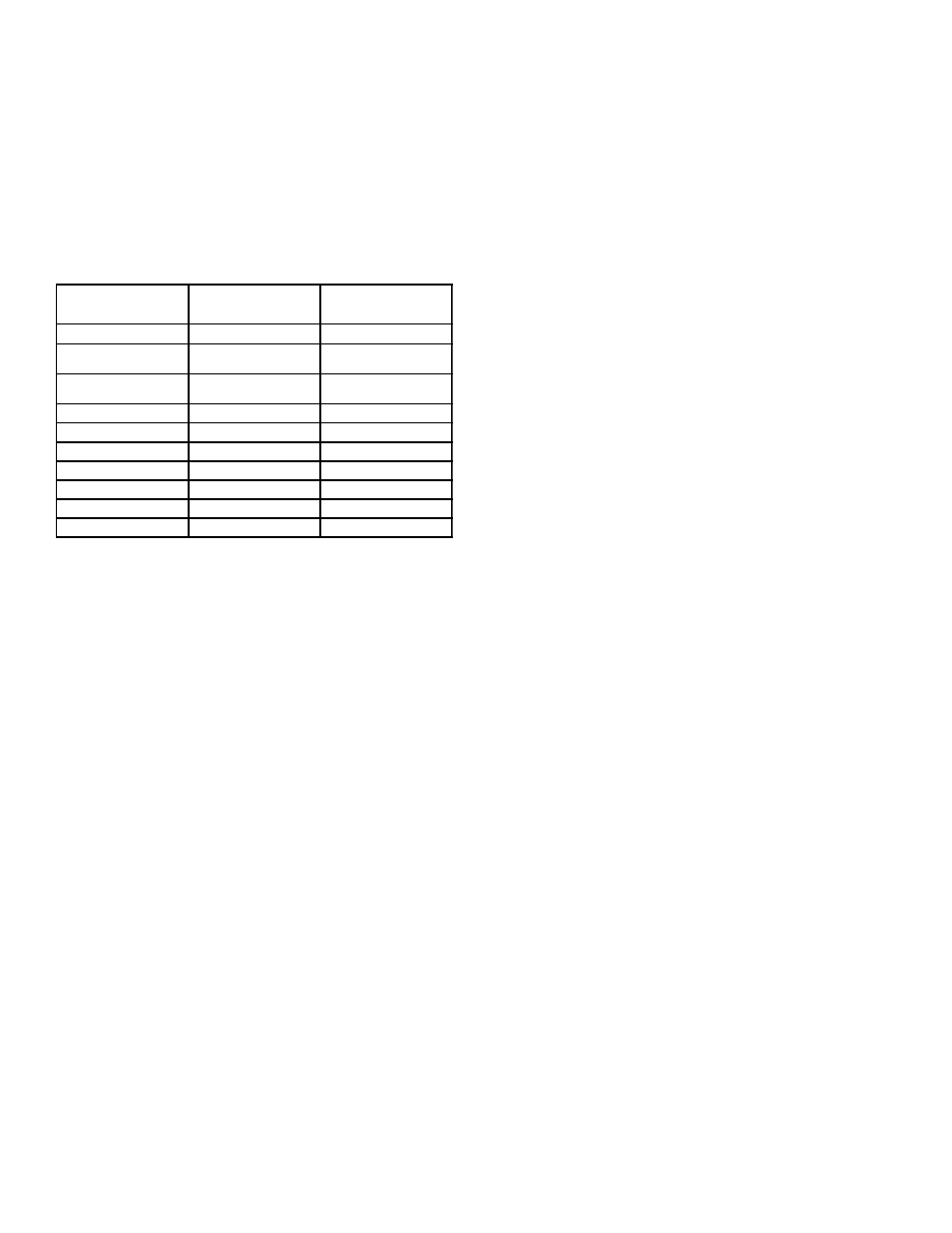

Table 2-1. Dimensions Ball Nut Storage Arbor

Actuator

Model No.

Ball Screw

Root Dia. (in)

Arbor O.D. (in)

28632

.480

.500

9803 2803

.820

.889

98031 28031

.820

.889

28004/98004

.870

.889

9806

1.140

1.156

9811

1.140

1.156

98111

1.140

1.156

9821

1.850

1.884

9826

2.480

2.500

2861

3.338

3.366

b. Holding arbor firmly against shoulder of ball

screw pilot (5), unthread lifting nut (24) from

ball screw (5). As lifting nut bearing balls

disengage from ball screw grooves (5),

center lifting nut on arbor and remove arbor

from ball screw pilot.

Note

Lift arbor and lifting nut together, holding in

place to prevent lifting nut from sliding off of arbor.

c. Pass binding wire through arbor and bind

lifting nut and arbor together.

Note

Keeping assembly together in this manner will

eliminate the need for complete assembly of the

lifting nut during reassembly go the actuator. Com-

plete actuator disassembly as follows:

4. Remove pipe (4) from shell (3) [upright units] or

from shell cap (2) [inverted units].

Note

Some models have an expansion plug (4a) in

place of pipe (4). If the expansion plug must be

replaced, it will be removed later per Step 18.

5. Remove set screw (10 from shell cap (2) and

remove shell cap from shell (3).

Note

It may be necessary to tap shell (2) with a

hammer to loosen shell cap.

6. Remove ball screw (5) and gear assembly (6)

from shell. For ease in removing ball screw and

gear assembly, loosen cap screws (9) holding

flanges (11) and shift worm (14) slightly.

Note

On some models it may be necessary to remove

worm before moving ball screw and gear assem-

bly (see Step 7 and 8).

7. Remove top bearing (7) which may be attached

to either shell cap (2) or worm gear assembly

(6).

8. Remove cap screws (9), lockwashers (10) and

flanges (11).

Note

Be careful not to lose flange shims (12).

For 1/2-ton Models - Remove four set screws

(9a) from shell (3) and unthread bushings (11a)

from shell.

9. Remove worm (14) and worm bearings (15)

from shell (3) by striking end of worm shaft with

a soft-head mallet or hammer.

For 1/2-Ton Model - Remove worm (14) with needle

bearings (15a) and races (15b) from shell (3)

and remove needle bearings and races from

worm.

10. Remove bottom load bearings (8) which may be

attached to either shell (3) or gear (6).

11. Press oil seals (13) out of flanges (11).

12. Remove bearings (15) from worm (14) with

puller or press.

Note

This step is not necessary if worm (14) or

bearings (15) are not damaged.

13. Remove set screw (21) from locknut (20).

Note

Some models may not utilize a set screw.

14. Restraining ball screw (5) from turning (use soft

jaws), remove locknut (20) from ball screw (5).

Note

If all parts are to be reused, match-mark end of

screw and locknut so that they can be reas-

sembled in the same order.

15. Remove worm gear (6) from ball screw (5).

Note

It may be necessary to tap on worm gear as-

sembly to remove it. Use a soft face hammer.

Do not tap on gear teeth.