1. general, 2. applications, 3. table of specifications – Duff-Norton Ball Screw Translating User Manual

Page 3: 4. important precautions

3

Section I

General Information

1-1. General

This manual contains maintenance instructions

for Duff-Norton translating ball screw actuators. It

describes and details procedures for installation,

disassembly, cleaning, inspection, and assembly of

these actuators.

1-2. Applications

The actuators described and illustrated in this

manual are intended for industrial use only and

should not be used to lift, support or otherwise

transport people unless you have a written state-

ment from Duff-Norton which authorizes the specific

actuator unit, as used in your application, as suit-

able for moving people.

These actuators are intended for a clean, non-

corrosive environment with ambient temperatures

ranging from -20 to 200 ° F. If your environment is

dirty and/or contains abrasive particles it is impor-

tant to protect the screw with a boot. If your atmo-

sphere is corrosive it is important to specify a non-

corrosive material or finish. Duff-Norton can provide

stainless steel, nickel plated or epoxy coated actua-

tors. If your duty is high or your use severe, more

frequent lubrication should be employed. Duff-

Norton publishes a Mechanical Actuator Design

Guide, Catalog No. 2003, which you may find

helpful in the selection and application of mechani-

cal actuators. If you need additional help, please

contact Duff-Norton at (800) 477-5002.

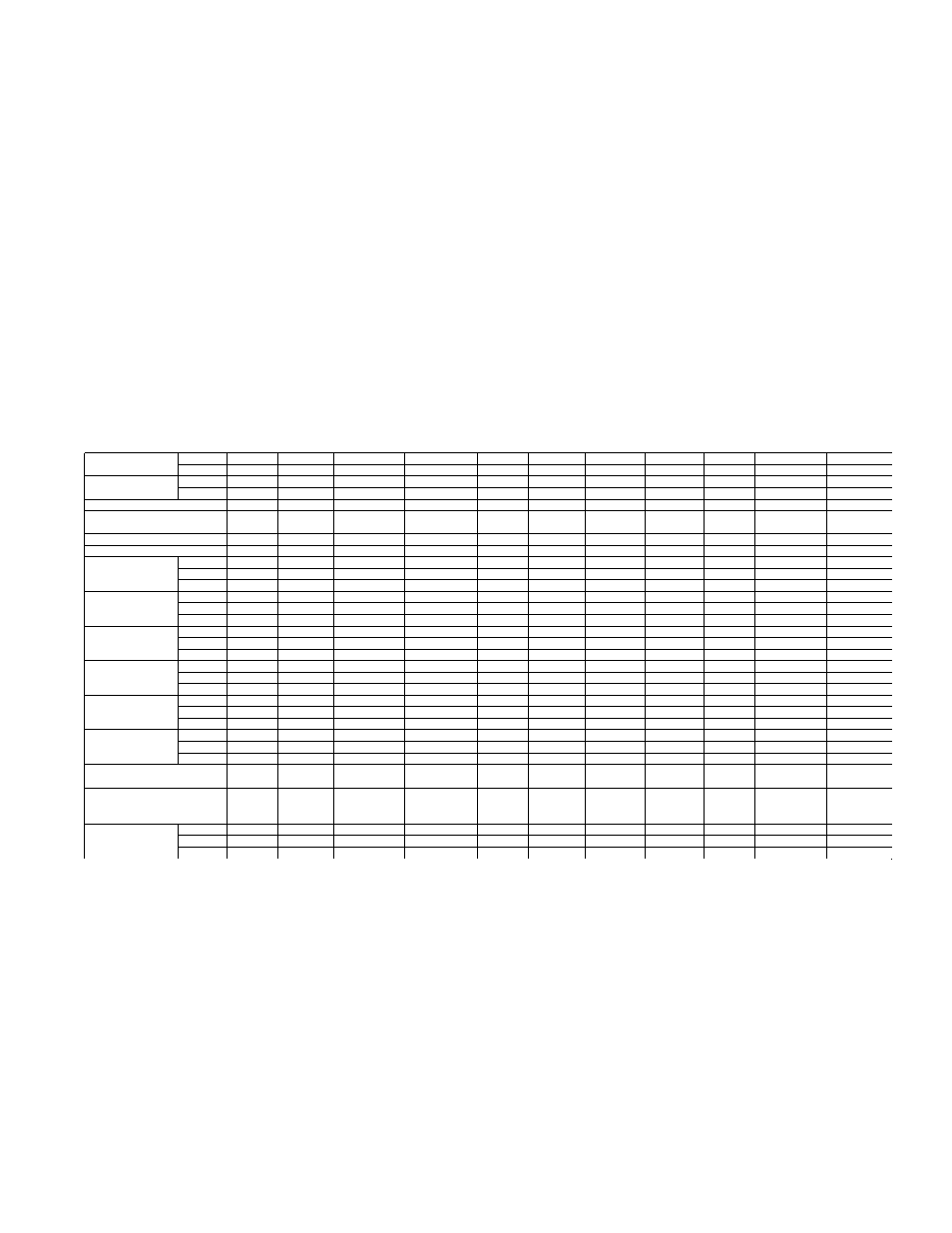

1-3. Table of Specifications

Note: Hold back torque is restraining torque at the worm shaft, to keep load from running down.

*Dimensionally same as Model 2802/9802

† Dimensionally same as Model 9805

‡ Dimensionally same as Model 9810

1-4. Important Precautions

To ensure that actuators provide good service

over a period of years, the following precautions

should be taken:

1. Select an actuator that has a rated capacity

greater than the maximum load that may be

imposed on it.

2. The structure on which the actuators are

mounted should have ample strength to carry

the maximum load, and should be rigid enough

to prevent undue deflection or distortion of the

actuator supporting members.

3. It is essential that the actuators be carefully

aligned during installation so that the lifting

screws are perfectly plumb and the connecting

shafts are exactly in line with the worm shafts.

After the actuators, shafting, gear boxes, etc.,

are coupled together, it should be possible to

turn the main drive shaft by hand. If there are no

signs of binding or misalignment, the actuator

system is then ready for normal operation.

Standard Actuator

Upright

28631

2802/9802

28021/98021*

28003/98003

9805

98051†

9810

98101‡

9820

9825

2860

Model Numbers

Inverted

28630

2801/9801

28011/98011

28002/98002

9804

98041

9809

98091

9819

9824

2859

Special Actuator

Upright

38631

3802/9802

3802/9802

38003/108003

10805

0805

10810

10810

10820

10825

3860

Model Numbers

Inverted

38630

3801/9801

3801/9801

38002/108002

10804

10804

10809

10809

10819

10824

3859

Rated Load (tons)

1/2

2

2

3

5

5

10

10

20

25

50

Diameter of

5/8

1

1

1 11/64

1 1/2

1 1/2

1 1/2

1 1/2

2 1/4

3

4

Lifting Scfew (inches)

.200 Lead

.250 Lead

1.000 Lead

.413 Lead

.474 Lead 1.000 Lead

.474 Lead

1.000 Lead

.500 Lead

.660 Lead

1.000 Lead

Closed Height (inches)

5

7 1/2

7 1/2

9 1/4

10 3/4

10 3/4

10 3/8

10 3/8

16 1/2

19 3/4

25 3/8

Base Size (inches)

2 1/4 x 4

3 1/2 x 7

3 1/2 x 7

3 1/2 x 7

6 x 8

6 x 8

7 1/2 x 8 3/47 1/2 x 8 3/48 1/4 x 11 10 1/4 x 13 3/4 9 3/4 x 19 3/4

Std Ratio

5:1

6:1

6:1

6:1

6:1

6:1

8:1

8:1

8:1

10 2/3:1

10 2/3:1

Worm Gear Ratios

Optional

20:1

12:1

24:1

12:1

24:1

24:1

24:1

24:1

24:1

32:1

32:1

Optional

—

24:1

—

24:1

—

—

—

—

—

—

—

Std Ratio

25

24

6

14.526

12.667

6

16.888

8

16

16.16

10.66

Turns of Worm

Optional

100

48

24

29.052

50.667

24

50.667

24

48

48.48

32

For 1˝ Raise

Optional

—

96

—

58.104

—

—

—

—

—

—

—

Std Ratio

1/3

2

2

2

4

4

5

5

5

8

15

Maximum H.P.

Optional

1/6

3/4

1/2

3/4

3/4

3/4

1 1/2

1 1/2

1 1/2

2 1/2

6

Per Actuator

Optional

—

1/2

—

1/2

—

—

—

—

—

—

—

Starting Torque

Std Ratio

10.5

50

180

110

220

500

350

800

700

925

2,700

at Full Load

Optional

5.0

30

80

68

90

206

175

400

325

475

1,500

(lb-ins)

Optional

—

25

—

50

—

—

—

—

—

—

—

Running Torque

Std Ratio

9.5

45

160

100

180

410

300

700

650

825

2,200

at Full Load

Optional

4.5

25

70

60

80

183

150

290

300

425

1,200

(lb-ins)

Optional

—

20

—

45

—

—

—

—

—

—

—

Std Ratio

65

59

59

59

70

70

65

65

61

60

55

Actuator Efficiency Optional

38

44

33

44

39

39

42

42

44

39

33

Rating (%)

Optional

—

33

—

33

—

—

—

—

—

—

—

Weight with Base

Raise of 6˝ (lbs)

2.75

20

20

21

40

40

50

50

115

235

520

Weight for Each

Additional 1˝ of

Raise (lbs)

0.1

0.3

0.3

0.4

0.9

0.9

0.9

0.9

1.5

2.9

5.0

Hold-Back Torque

Std Ratio

1

2

2

7

8

8

11

11

24

24

92

at Rated Load

Optional

0.5

1

0.5

2

0.5

0.5

0.5

0.5

2

2

33

(lb-ft)

Optional

—

0.5

—

0.5

—

—

—

—

—

—

—