Select a site for the console, Option #1 surface mounting without mounting box, Option # 2 surface mounting with mounting box – Winland Electronics WB800 User Manual

Page 3: Step 1 - power connections, Option 2 - unsupervised probe mode, Step 3 - alarm relay connections, Step 5 - optional remote buzzer connection, Step 6 - setting the audible silence timer, Audible delay, Jumper jp1

S

YSTEM

O

VERVIEW

The WB-800 is a completely electronic water detector which is designed to detect only

nonflammable conductive liquids (distilled and deionized water cannot be detected).

The WB-800 is designed with the control console mounted on the wall and the remote

probes placed in locations where water seepage is most probable.

The unit includes four (4) supervised surface probes (W-S-S). In addition to detecting

water with this probe, the unit will alarm when the supervised probe line becomes

disconnected.

A film of moisture forming a bridge between the two metallic contacts on any remote

probe is all that is needed for the unit to signal an alarm condition (Figure 1). The relay

output is non-latching, but will remain closed until the moisture bridge between the

two contacts is broken. As sensitive as the WB-800 is, it will not alarm due to high

humidity or condensation. The WB-800 is ideal for use around homes, office buildings,

computer rooms, boats, etc. Additional features include:

• Accepts 12V, 24V AC/DC power input

• Eight alarm LED indicators to identify the probe zone in alarm.

• Supervised probe line option. Unit will alarm on open probe condition and an

indicator will light. Up to 8 supervised probes per console (W-S-S or W-UC-S).

Probe lines up to 500ft.

• One “Form C” SPDT Relay for alarm output.

• Built in audible alarm and remote buzzer output with silence feature (adjustable

3 seconds to 150 minutes)

C

ONSOLE

M

OUNTING

C

ONSIDERATIONS

Select A Site For The Console

Probe cable lengths and power source locations should be considered. Maximum cable

length for the water probes is 500 ft.

Option #1 Surface Mounting Without Mounting Box

It is possible to install the console on a soft wall (sheet rock, panel, etc.) without the

use of a mounting box. This is the fastest mounting method and it gives the control

console a nice looking low profile. In selecting a site to mount the console, keep in

mind that it must be placed in a secure, dry location with an ambient temperature

of 32˚ to 130˚F (0˚ to 54˚C). For this option, drill a ½” diameter hole(s) in the wall

which will be opposite the wiring terminal strip on the console. This hole will provide

access for all wiring. Next, carefully mark the location of the four corner screw holes

on the console. Then drive four wall anchors into the proper locations and complete by

attaching the console to the wall.

Option # 2 Surface Mounting with Mounting Box

In areas where no hollow interior walls are available, the included standard 3-gang

surface mounting box can be secured to any wall. The installed profile of the WB-800

with this option is about 2½“ out from the wall.

I

NSTALLATION

- P

OWER

AND

P

ROBE

C

ONNECTIONS

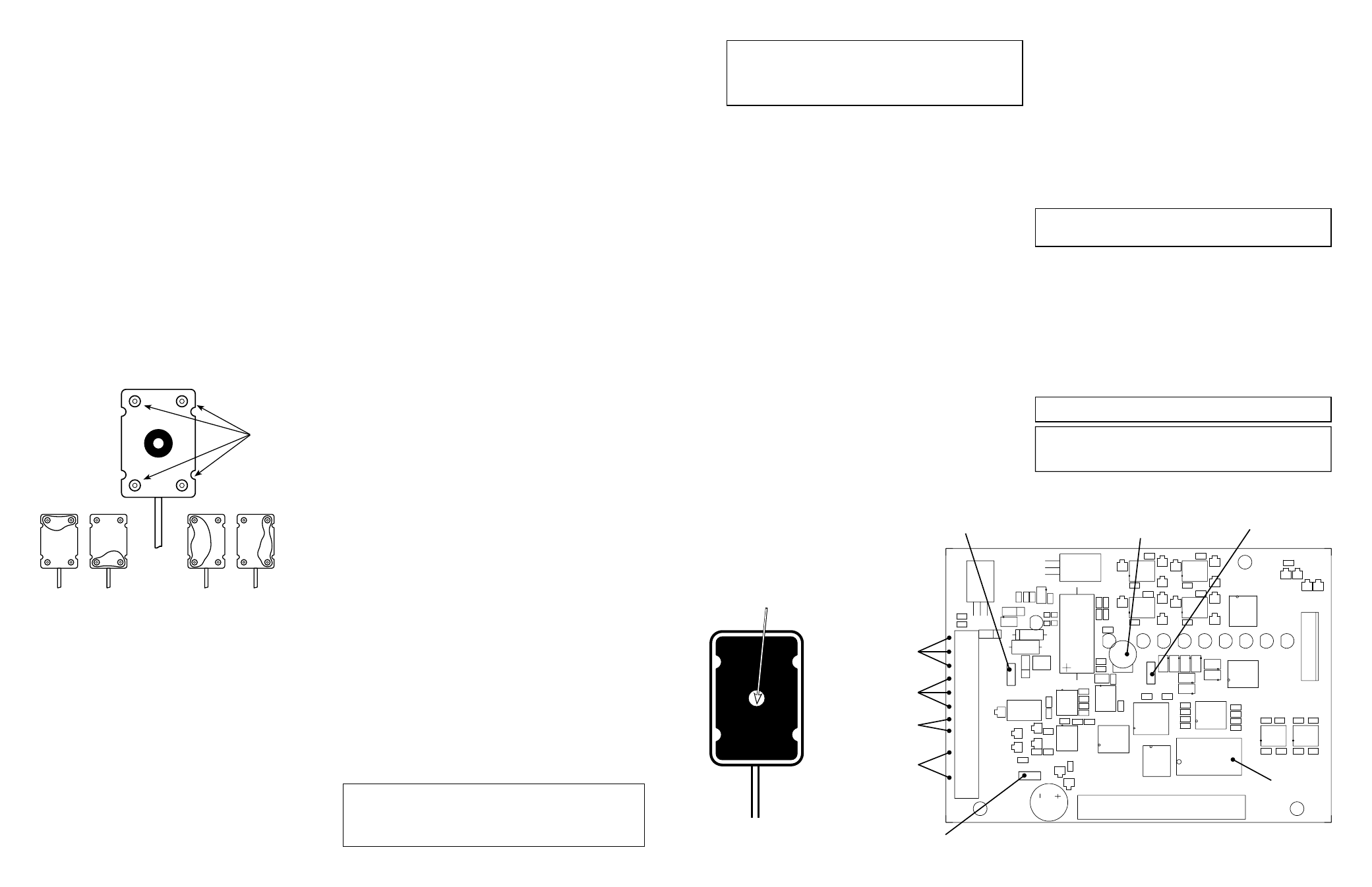

Step 1 - Power Connections

The WB-800 will operate on 12V, 24V AC/DC. Refer to Figure 3 for proper connections.

Note: Before making wire connections, set jumper “JP3” to either 12V or 24V

depending on your power supply output.

Connect your power input to two of the three positions on the terminal block.

Regardless of your voltage input, connect the negative side to “V-“. If your supply is

12V AC/DC or 24VAC, connect the positive side to the position marked “12VAC/DC,

24VDC”. If using 24VAC input, connect to the 24VAC input.

When the power is applied, the green ON power indicator should be on.

Note: If the built-in buzzer sounds, it can be disabled by moving jumper “JP2” to the

OFF position. If desired, toward the end of installation, it can be reactivated.

Important: If you are not using Winland’s 12VDCT power supply accessory with this

product, ensure that your power supply does not have a connection to earth ground.

If the WB-800’s power is connected to earth ground, it’s possible that the sensor will

fail to alarm when wet due to the possibility of a ground loop that may exist from the

sensor terminals through the earth back to the power supply. This will change the

system’s voltage reference, which will, in turn, change its trip point. In all cases, test

the system to ensure it will trip as expected when water is encountered.

Step 2 - Probe Connections

Option 1 - Supervised Probe Mode

The unit includes four supervised surface probes (W-S-S). Additional probes (surface

[W-S-S] or under carpet [W-UC-S]) may be purchased separately.

With no probes attached to unit and with the 8 position DIP switch settings (SW1)

in the down position, zone alarm indicators 1-8 and the probe line alarm indicator

should be on. When the probe line alarm indicator is on, it shows there is an open

probe line. When the zone alarm indicator is on, it shows that a specific zone is in

alarm (either water detected or open probe line).

For zones that are not planned to be used, the supervised mode can be disabled

(i.e. open probe line alarm turned off) by pushing the DIP switches up for the

corresponding zones.

The WB-800 has two terminal blocks (TB1 and TB2) that are the locations for

connecting the probe inputs. There is no polarity to the probes. The probes are

included with 15’ (4.5 m) of cable. The probe cables can be increased to 500’ (152.4

m) with additional cable (22-18 AWG twisted pair, is recommended). Be sure that all

splices are moisture proof.

Note: For probe placement and mounting, see Figures 1 and 2.

Option 2 - Unsupervised Probe Mode

The WB-800 can also be used with the unsupervised surface probes (W-S-U) and the

unsupervised under carpet probes (W-UC-U). These probes are used with Winland

models WB-200 and WB-350. With unsupervised probes, up to two probes can be

connected per zone. However the probe lines are not supervised (i.e. break in probe

lines will not cause an alarm). To use this type of probe the DIP switch zones must be

pushed to the “up” position to disable the supervised probe mode.

Caution: Unsupervised probe mode is only advised if the WB-800 is used to replace

an existing model such as the WB-200 when existing probes are planned to be

used. Unsupervised probe mode may also be used when more than eight probes are

required for the application. To take maximum advantage of the WB-800, supervised

probes are recommended.

Step 3 - Alarm Relay Connections

The WB-800 includes one Form C (SPDT) Relay. This relay is activated when power is

applied and the unit is not in water detect or open probe mode. This feature provides

power-on supervision in case of power loss.

Note: When power is applied and unit is not in alarm, a short exists between “NC” and

“C”, and an open exists between “NO” and “C”.

Step 4 - Installation- Audible Alarm and Silence Features

The WB-800 has a built-in audible alarm which will sound on an alarm condition. An

audible silence feature is included that will disable the buzzer for a time period that

can be set from 3 seconds to 150 minutes. This feature is important in installations

where a constantly sounding alarm might disrupt business. It allows the audible alarm

to be suspended while you wait for the water to be cleared from the affected probe.

Note: During this time, the alarm indicators and the relay outputs will remain in

alarm condition as long as unit is still in an alarm condition.

Note: Jumper “JP2” can be set to enable or disable the built-in buzzer.

Step 5 - Optional Remote Buzzer Connection

The WB-800 is capable of driving an external 12VDC buzzer (BZ-1). The buzzer is

connected to the terminal block as per Figure 3. As with the built-in buzzer, the

remote buzzer can be temporarily disabled by the audible silence feature.

Step 6 - Setting the Audible Silence Timer

The built-in audible silence timer provides an external means of silencing the audible

alarm for a user selectable period (3 seconds to 150 minutes). Set jumper “JP1” to

seconds or minutes. Adjust “Audible Delay” to the number of seconds or minutes

desired.

Note: If a great amount of accuracy is required in setting the number of minutes, the

jumper should first be placed in the seconds mode and then force the unit to alarm.

The number of seconds the audible alarm was silenced corresponds to the number of

minutes. When satisfied with setting, place JP1 back to minutes position.

Figure 1

WATER

WATER

W

ATER

W

ATE

R

ALARM

NO ALARM

Four Probe Contacts

Mount the probe to

ensure these four

stainless steel contacts

are against the surface

to be monitored.

F

IGURE

3

Important: Before applying power,

make sure Jumper 3 “JP3” is in the

proper position.

12V or 24V

Audible delay:

Adjustable from 3-150

seconds or minutes -

depending on JP1 position.

24 VAC

V -

N/C

C

N/O

+

-

S1

S1

S2

S2

12V

24VDC

S3 S3 S4

S4

S5

S5

S6

S6

S7

S7 S8 S8

LED

9

LED

8

LED

7

LED

6

LED

5

LED

4

LED

3

LED

2

LED

10

LED

1

Push SW1

up to disable

supervised probe

input mode.

SW1

Zones

1 2 3 4 5 6 7 8

Probe Input Zones 3 - 8

BZ-1

JP2

On

Off

Buzzer

Select

Volts

12V

24V

JP3

Sec

Min

JP1

Buzz

er D

ela

y

Jumper JP1

Silence delay set for

minutes or seconds.

12, 24 V AC/DC Input

Note: Separate

positions for 24 VAC

Relay OUT

External Buzzer +

External Buzzer -

(25mA max)

Probe Input Zones 1-2

Jumper JP2

Left = Built in buzzer “Off”

Right = Built in buzzer “On”

Caution: If a supervised probe is used, and the zone DIP switch is inadvertently left

in the “up” position (supervised mode disabled) the probe will still be operational to

detect water, however, the open probe line alarm will not be operational. Verify the

DIP switch is in the “down” position for zones being used.

Important: Upon completion of a supervised probe installation, disconnect the

probe line from the terminal block to verify the probe line and zone indicators light

(alarm). The unit should go into alarm within approximately 3 seconds.

Caution: Use only the BZ-1 buzzer due to the units extremely low current draw.

Using another buzzer may affect the performance of the WB-800.

To insure proper operation, test weekly.

Drill only in the

innermost area.

F

IGURE

2

Concrete can be semi-conductive. If experiencing false alarms,

insulate all probes mounted on concrete.