WIKA SF6 User Manual

Page 2

Technical alteration rights reserved.

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg

•

Germany

Phone (+49) 93 72/132-0

Fax

(+49) 93 72/132-406

E-Mail [email protected]

www.wika.de

9078061 01/2003 GB/D/F

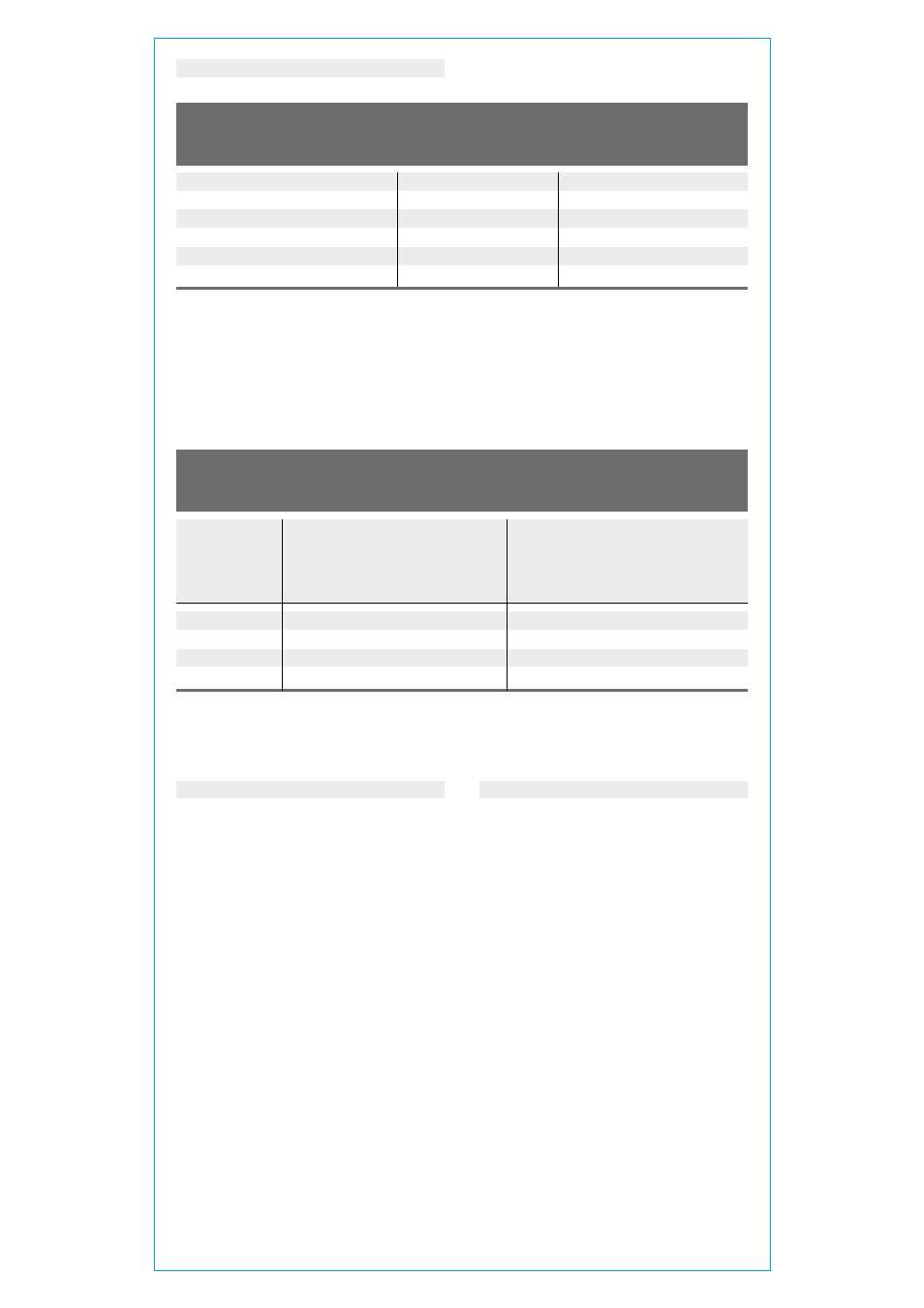

10. Power ratings

Table 1: Maximum contact rating

Maximum contact rating

Magnetic snap-action contact model 821

with non-inductive

Gas filled gauges

Liquid filled gauges

(ohmic) load

Maximum voltage (MSR) U

eff

250 V

250 V

Current ratings:

Make rating

1.0 A

1.0 A

Break rating

1.0 A

1.0 A

Continous load

0.6 A

0.6 A

Maximum load

30 W 50 VA

20 W 20 VA

Note: None of the limit values for voltage,

current and capacity are to be exceeded!

We recommend the following load values to

ensure safe, continuous operation:

Table 2: Recommended contact ratings with

different nominal voltages and instrument

versions

Voltage

Magnetic snap-action contact model 821

(DIN IEC 38)

Gas filled gauges

Liquid filled gauges

DC / AC

ohmic load

inductive

ohmic load

inductive

load

load

DC

AC

cos

ϕ

>0.7

DC

AC

cos

ϕ

>0.7

V

mA

mA

mA

mA

mA

mA

230

100

120

65

65

90

40

110

200

240

130

130

180

85

48

300

450

200

190

330

130

24

400

600

250

250

450

150

The switching current must not be less than 20 mA

with low voltages for switching reliability reasons.

11. Overcurrent protection devices

No overcurrent protection devices are installed

in the instruments.

Should overcurrent protection devices be

required we recommend the following values in

accordance with EN 60 947-5-1.

Voltage 24 V:

2 A

Voltage 250 V:

1 A

Data refers to miniature fuses M and

a maximum short circuit current 100 A.

12. Repairs / Complaints

Repairs are to be carried out by the

manufacturer only. The instruments must not be

opened, as this would result in indication and

switching point errors.

In the case of complaints the manufacturing and

product identification numbers have to be

stated. The manufacturing number is indicated

on the dial, the product identification number on

the type plate. When measuring, the

atmospheric pressure, the temperature during

measurement and the data of the reference

standard (model, class) always have to be

indicated.

The density monitors have to be exposed to a

specific temperature long enough (at least 2

hours) to ensure temperature equalisation.

For higher loads, and instruments with liquid-filled

cases, we recommend the use of a separate relay,

WIKA Models 905.1X.