WIKA 233.50 User Manual

Page 3

Permissible vibration load at the installation site

The instruments should always be installed in locations free from vibration.

If necessary, it is possible to isolate the instrument from the mounting point by instal-

ling a flexible connection line between the measuring point and the pressure gauge and

mounting the instrument on a suitable bracket.

If this is not possible, the following limit values must not be exceeded:

Dry gauges:

Frequency range < 150 Hz

(Model 232)

Acceleration < 0.7 g (7 m/s

2

)

Liquid-filled gauges: Frequency range < 150 Hz

(Model 233)

Acceleration < 4 g (40 m/s

2

)

The liquid filling must be checked on a regular basis.

The liquid level must not drop below 75 % of the gauge diameter.

4. Commissioning

During the commissioning process pressure surges must be avoided at all costs. Open the

shut-off valves slowly.

5. Maintenance and cleaning

The instruments are maintenance-free.

The indicator and switching function should be checked once or twice every year. The

gauge must be disconnected from the process to check with a pressure testing device.

Clean the pressure gauge with a moist cloth.

Repairs must only be carried out by the manufacturer or appropriately qualified skilled

personnel.

When dismounting, close the compensating valve (if available).

WARNING!

Residual media in dismounted pressure gauges can result in a risk to persons,

the environment and equipment.

Take sufficient precautionary measures.

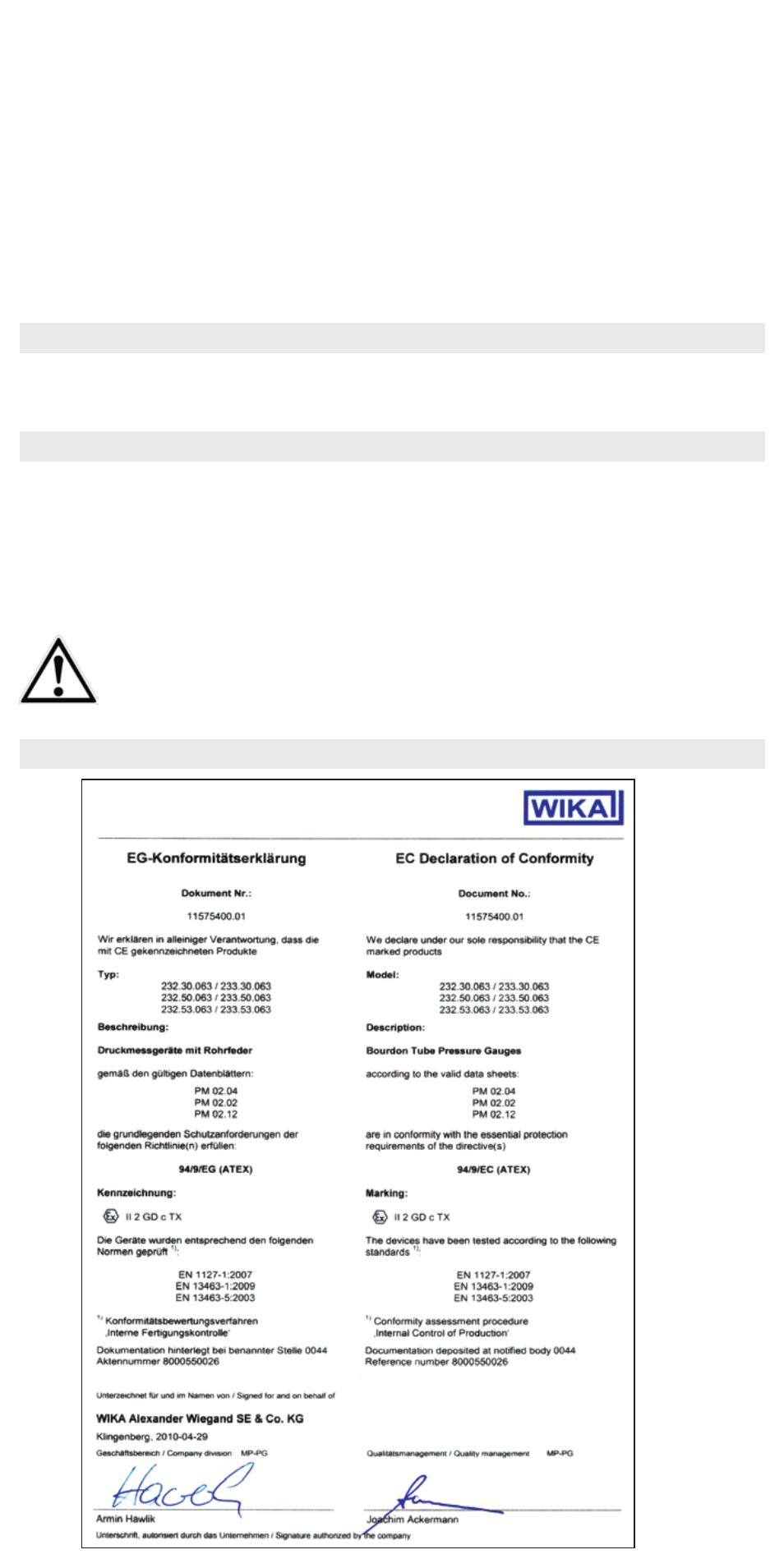

Appendix 1: Declaration of conformity