DuraVent FasNSeal W2 Double-Wall User Manual

Page 8

8

opening, gas utility meter, service regulator or

the like. It also shall terminate at least 3’ (.9m)

above any forced air inlet within 10’ (3.1m)

and shall terminate at least 4’ (1.2m) below, 4’

horizontally from or 1’ (.3m) above any door,

window, or gravity air inlet into any building as

provided in the National Fuel Gas Code aNSI

Z223.1 and NFPa 54. Proper judgement may

require greater distances depending on the

size of the equipment installed or to allow for

snow drifting or falling from overhead roofs or

trees. the termination should be far enough

away from trees, shrubs or decorative items to

prevent damage.

• the total vent length from the appliance

flue collar to the outside termination shall not

be greater than specified in the appliance

manufacturer’s instructions.

• a horizontal installation shall have a slope

(upwards or downwards for Category II, III, or

IV appliances) of no less than 1/4” (6.4mm)

every 12” (305mm) to prevent collection of

condensates, formation of ice build up, or

blockage at any location within the assembly.

Refer to appliance manufacturer’s installation

instructions for further details regarding the

installation of condensate drain fittings and the

pitch of the system.

• Use non-combustible hanger straps a

minimum of every 6’ (1.8m) to support the

vent system from ceiling joints or other solid

structures. Do not puncture the vent system!

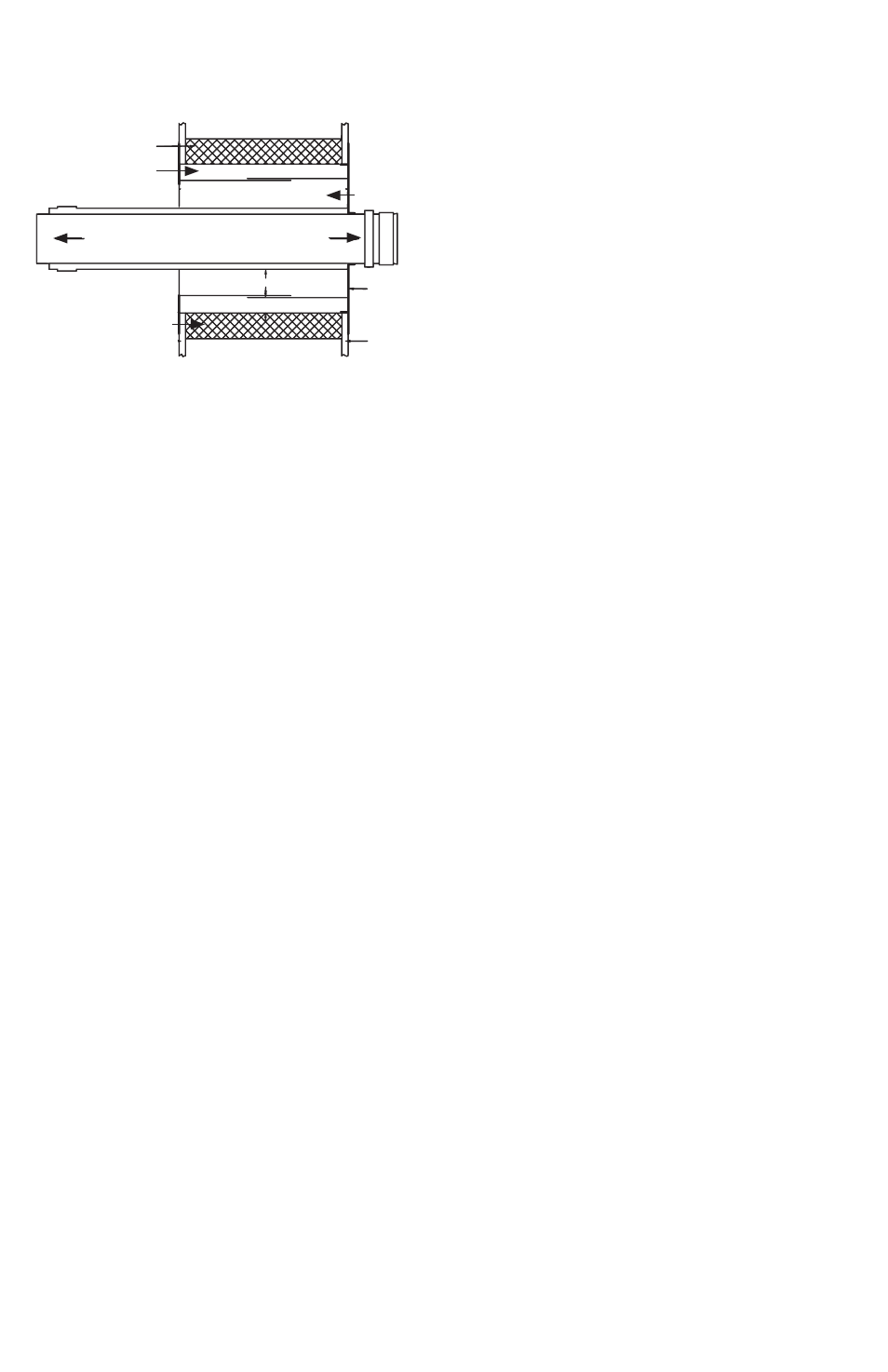

1. Determine the location and install the Wall

thimble so that a continuous minimum slope

of 1/4” per foot is maintained in any horizontal

portion of the vent system.

Condensate must flow freely and may not

be retained in any part of the vent system.

2. Cut the opening for the Wall thimble to

allow the spacer tabs protruding from the outer

plate to sit comfortably within the opening.

(See Wall thimble Installation diagram)

• NOTE: the opening for the W2 Wall thimble

will be 6-inches larger than the vent diameter,

e.g. 3” vent system will need an wall opening

of 9” to allow spacer tabs to rest within the

opening.

3. Position Part a into the opening so that the

gasketed end of the Wall thimble is located on

the outside of the structure.

4. apply a bead of silicone between the two

surfaces and around the edges before nailing

or screwing the plate on Part a to the outside

of the structure.

5. From the inside, slide the sleeve of Part B

onto the sleeve of Part a until Part B’s plate

is flush against the inside structure surface.

Fasten with screws or nails.

• NOTE: When terminating through a non-

combustible wall, the wall thimble is optional.

6. Use a termination tee or a Birdscreen to

finish the system’s exterior.

7. When the vent system must pass through

an interior wall, use a Wall Pass through

(FSWPt). Cut the same size hole for the

FSWPt as was cut for the Wall thimble and

install using the same method.

8. assemble FasNSeal W2 from the appliance

towards the Wall thimble. Refer to “Joint

Connections” in these installation instructions

Wall Thimble Installation

OuTSide

BuiLding

SurFAce

inSide BuiLding

SurFAce

PArT B

1.0”

PArT A

1.5”

TO TerminATiOn

4.3” - 8.6”

2” x 6” STud

(cOmBuSTiBLeS)

TO APPLiAnce