Installation, Warning – Graymills DDP .375' Pump OMI User Manual

Page 10

10

Installation

Air Exhaust Ventilation

FIRE AND EXPLOSION HAZARD

Be sure to read FIRE OR EXPLOSION

HAZARD and TOXIC FLUID HAZARD

on page 2, before operating this pump.

Be sure the system is properly ventilated for

your type of installation. You must vent the

exhaust to a safe place, away from people,

animals, food handling areas, and all

sources of ignition when pumping flam-

mable or hazardous fluids.

Diaphragm failure will cause the fluid being pumped to

exhaust with the air. Place an appropriate container at

the end of the air exhaust line to catch the fluid. See

Fig. 8.

WARNING

The air exhaust port is 3/8 npt(f). Do not restrict the air

exhaust port. Excessive exhaust restriction can cause erratic

pump operation.

To exhaust to a remote location:

1.

Remove the muffler (11) from the pump air exhaust

port.

PRESSURIZED EQUIPMENT HAZARD

To reduce the risk of serious eye injury from

ice particles, never operate the pump with

the air exhaust port open. Ice may form

during pump operation, and ice particles will be ejected

from the port along with the exhaust air. If the muffler

(11) is removed, always connect an air exhaust hose to

the exhaust port.

WARNING

2.

Install an electrically conductive air exhaust hose (X)

and connect the muffler to the other end of the hose.

The minimum size for the air exhaust hose is 3/8 in.

(10 mm) ID. If a hose longer than 15 ft (4.57 m) is

required, use a larger diameter hose. Avoid sharp bends

or kinks in the hose.

3.

Place a container (Z) at the end of the air exhaust line

to catch fluid in case a diaphragm ruptures. If the fluid

is flammable, ground the container. See Fig. 8.

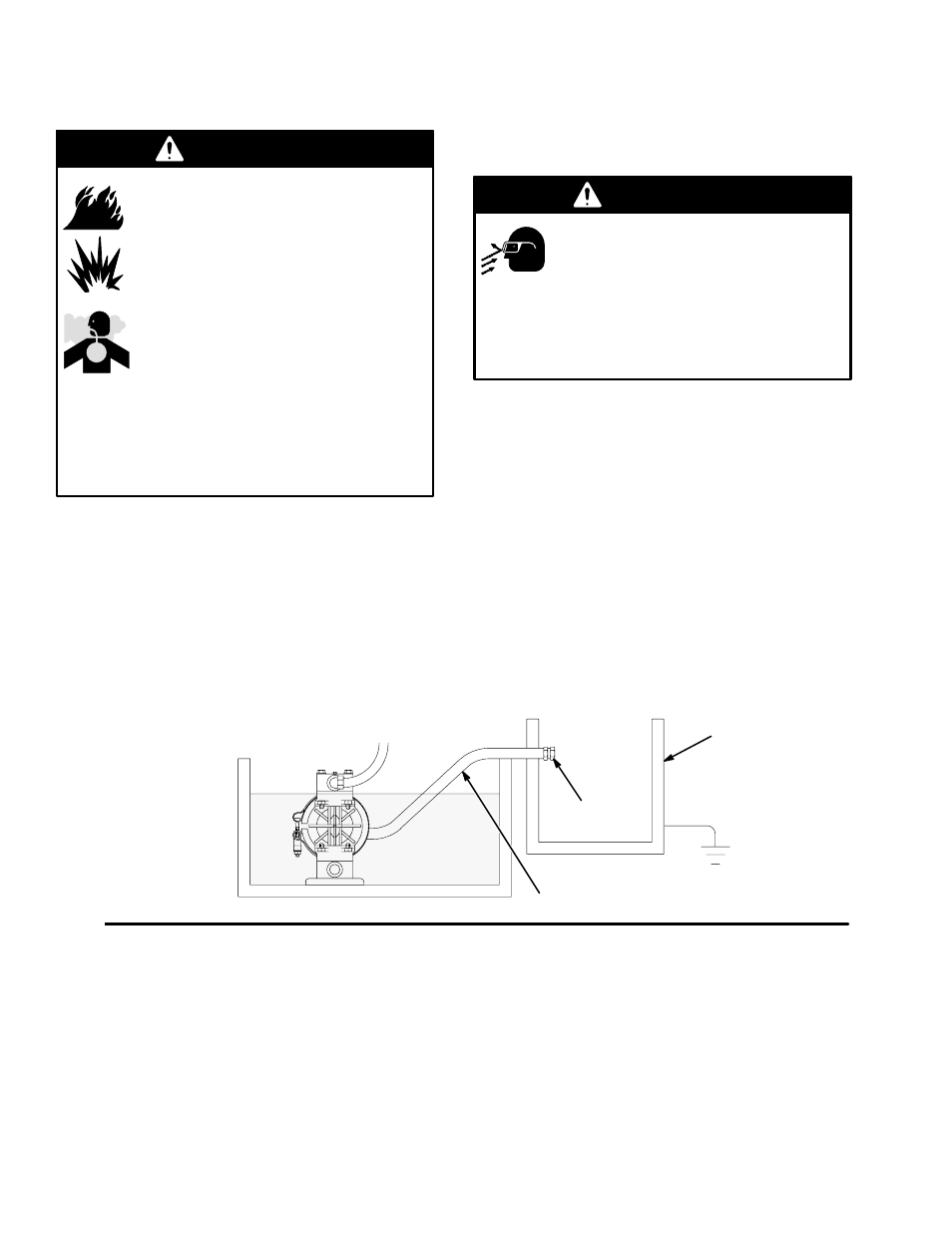

Fig. 8

VENTING EXHAUST AIR (Submerged Installation Shown)

See Fig. 4 for accessories

In a submerged installation (as shown), all wetted and non-wetted pump

parts must be compatible with the fluid being pumped.

01445A

Z

X

11