Installing bearing cartridge- qc and qce versions, Qc and qce versions – Graymills QC User Manual

Page 2

795-91382

02-10

Graymills Corporation – 3705 N. Lincoln Ave. – Chicago, IL USA – www.graymills.com

4. Holding lower section stationary, rotate upper shaft clockwise to unlock sections and then

continue to loosen by hand. Once loose, you can also rotate bearing cartridge to separate the

upper and lower sections of the shaft.

5. Remove bearing cartridge and upper shaft by pushing up from shaft end. The upper shaft is

retained in bearing cartridge.

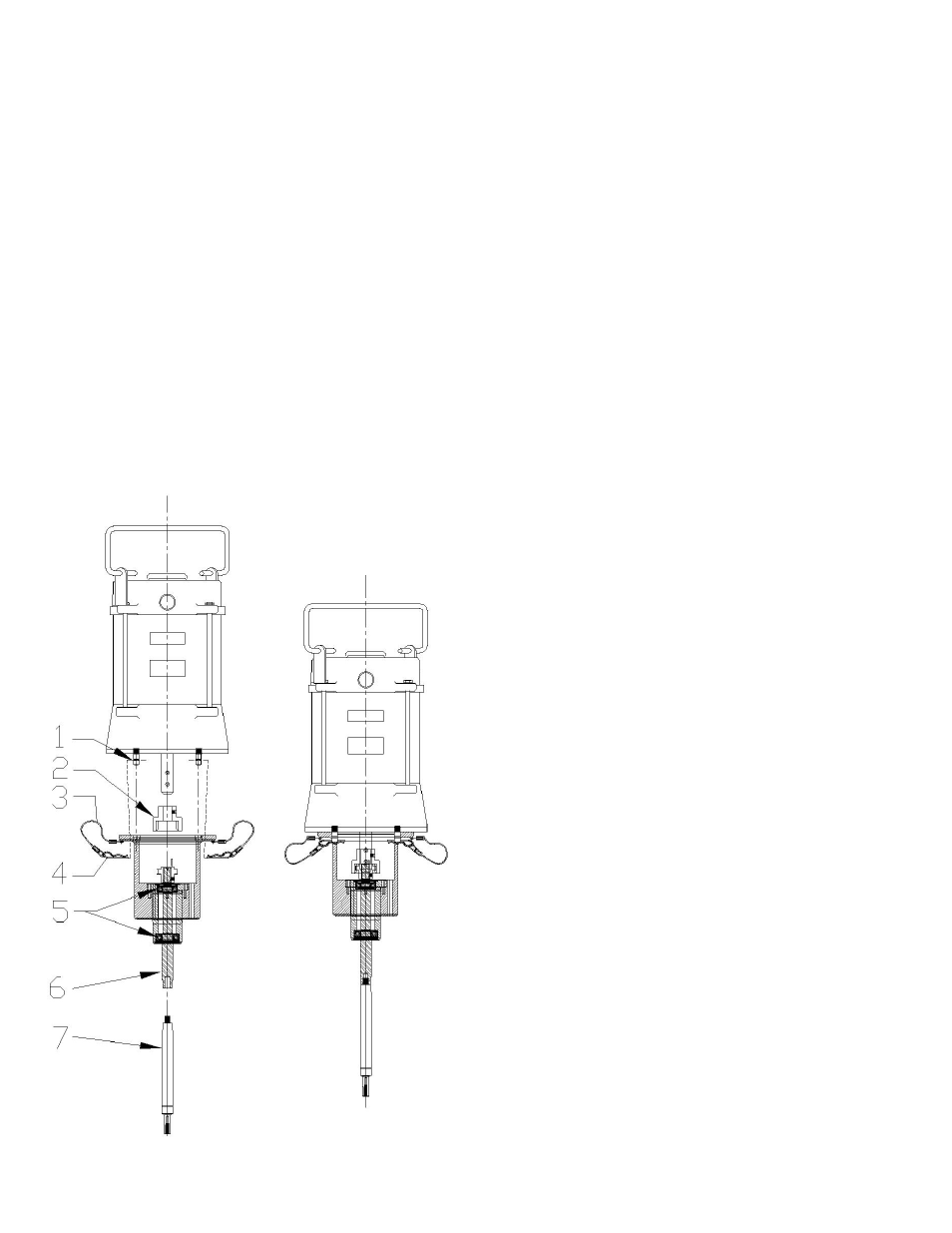

Installing Bearing Cartridge- QC and QCE versions

1. Place bearing cartridge containing upper section of shaft into bearing housing

2. Holding upper shaft stationary using one 5/8” open end wrench on the straddle-milled slot,

tighten the lower section using second open end wrench on its straddle-milled slot. NOTE:

Shafts are threaded with a left-hand thread, thus tightening requires turning counter-

clockwise.

3. Install (2) 4mm screws inside bearing housing and tighten with hex key.

NOTE: A 3-phase motor can be wired to run in reverse; however, this will cause the shaft to

loosen during operation, due to the left-hand thread of the shaft. Flow will also be reduced by

90%

QC and QCE Versions

Part Numbers

1.

Retaining Pin

568-38859-88

2.

Coupling Set

QC

Models

C-37717

QCE

Models

C-37718

3.

Lanyard 765-91349-13

4.

Hair Pin Clip

756-91348

5.

Bearing Service Kit

QC

Models

C-38983

QCE

Models

C-38984

6.

Upper Pump Shaft

QC

Models

560-38821-86

QCE

Models

560-38814-86

7.

Lower Pump Shaft

QCM3 (before 5/1/06)

560-38820-86

QCM3 (after 5/1/06)

560-39534-86

QC4000

560-38954-86

QC3

560-39174-86

QCME3 (before 5/1/06)

560-38820-86

QCME3 (after 5/1/06)

560-39534-86

QCE4000

560-39534-86

QCE3

560-39174-86

QCWE2

560-41020-86

QCGE2 560-41020-86