Chemglass CG-4600-01 User Manual

Page 9

9

3.6 Using the Regulator for Vacuum Distillations. This version of the vacuum regulator is intended for

medium accuracy vacuum applications, such as rotary evaporators. We say medium accuracy applications

because the regulator usually regulates pressure from ± 0.5 to ± 2 torr (as opposed to a high accuracy

regulator that controls pressure to better than ±0.1 torr). Some vacuum distillations are not affected by

changes in pressure of ± 0.5 torr, but many are. This regulator is not recommended for small, laboratory

scale vacuum distillations. Having said that, we at J-KEM know you’re going to try it anyway, so let us

help you set the distillation up to deliver the best performance possible.

Points to follow:

1. Use a precision needle valve (available from J-KEM) between the vacuum pump and the vacuum

regulator. Adjust the opening of the valve after reaching the set point pressure of the distillation to

minimize fluctuations.

2. Use a cold trap between the distillation set up and the vacuum regulator.

3. The pressure reading begins to lose linearity below 12 torr. The pressure reading will be consistent, but

its absolute value may be off by as much as 2 torr.

4. Good luck and give us a call if you need additional assistance.

[NOTE: J-KEM does manufacture a precision computer controlled high accuracy vacuum controller, our

DVR-1000]

3.7 Correcting Offset in the Displayed Pressure. A small amount of error can develop in the displayed

pressure (≈ 2 torr) of the vacuum regulator. This is due to the wide pressure range of the transducer used and

accuracy better than this is usually not possible. For display errors larger than 2mm, the controller can be

calibrated using the procedure below (For users experienced with J-KEM’s meter, do not correct pressure

using the “

ZEro” function. This introduces an error, not a correction). Before beginning this procedure you

will need to know the correct barometric pressure inside your lab.

This procedure should only be performed by a qualified electrician.

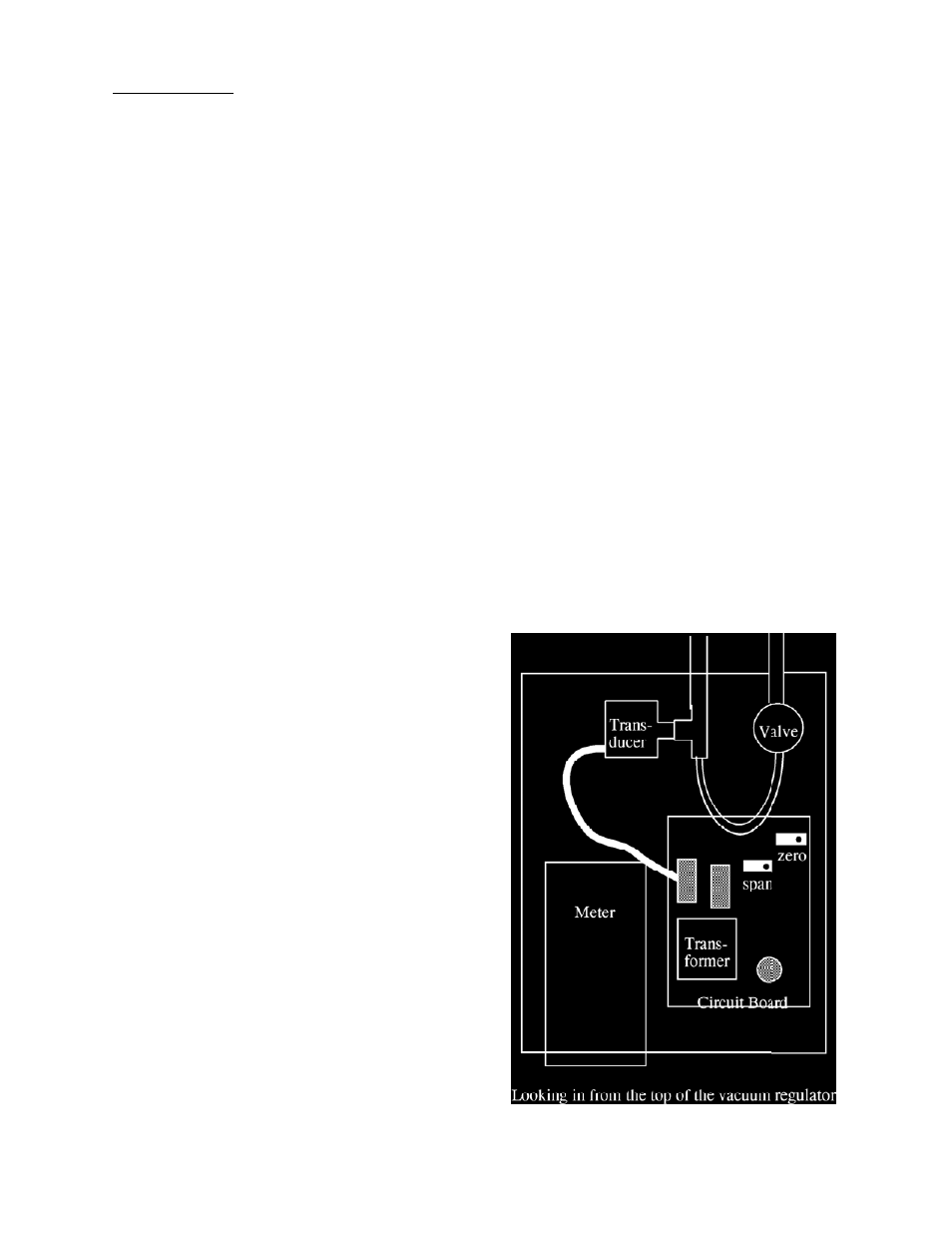

1. Remove the controller’s cover.

2. Plug the OUTLET port of the regulator and set

the regulator selection switch to the FULL

VACUUM position.

3. Let the controller warm up for 10 minutes.

4. Connect a vacuum pump to the INLET port, turn

it on and let it evacuate the controller to as close

to 0 torr as possible. Measure the pressure in the

system using a manometer. The regulator must

be evacuated to as close to 0 torr as possible

before the adjustment in step 5 is performed.

5. Adjust the “Zero” pot until the reading on the

meter matches the actual pressure.

6. Turn the vacuum pump off and unplug the

OUTLET port. Adjust the “Span” pot until the

meter reads the actual barometric pressure in the

lab.

7. Turn the controller off and replace the cover.