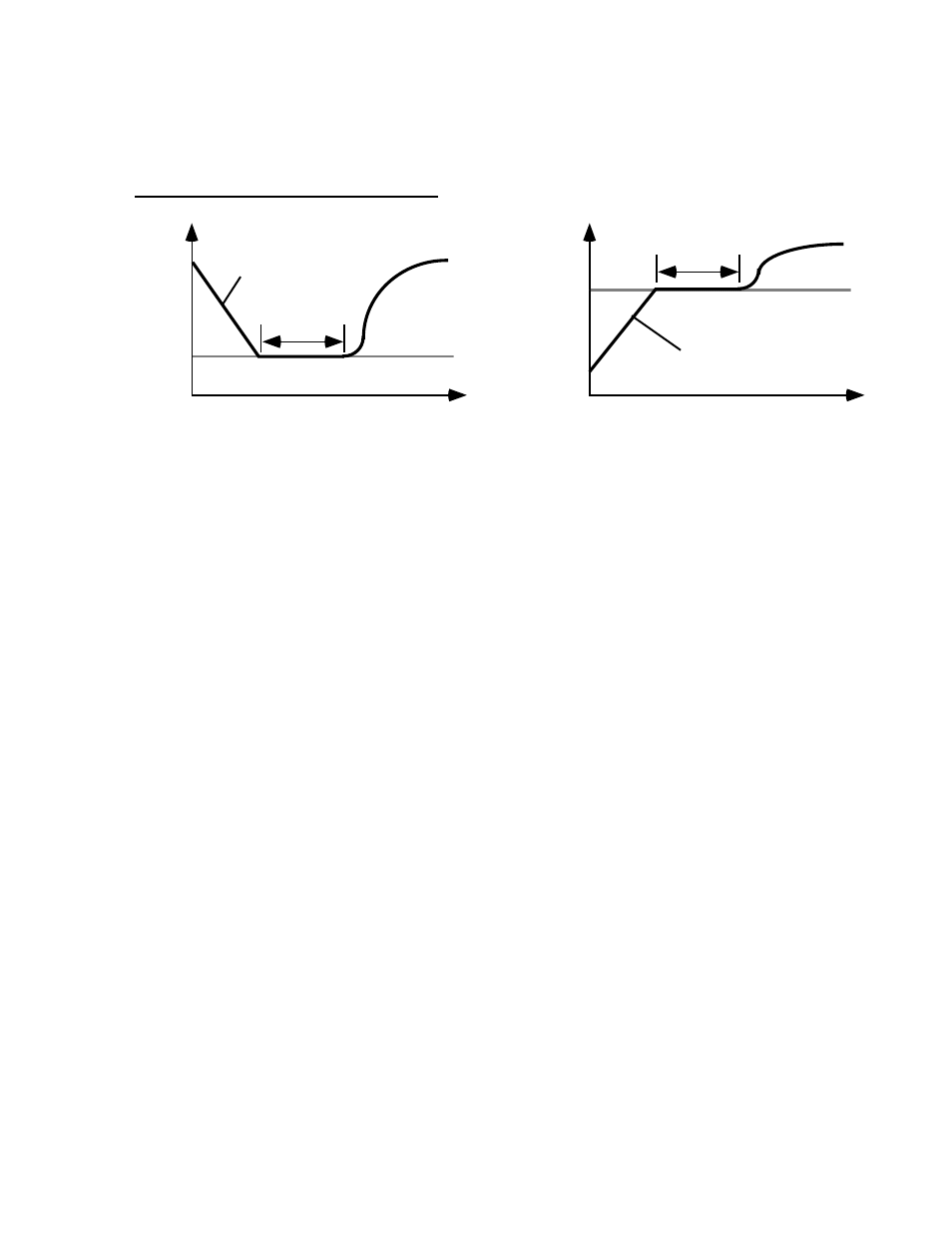

Example of program ramps, Sprr, Sprn – Chemglass CG-4600-01 User Manual

Page 6: Soak

6

3.3

Ramp-to-Setpoint & Soak Feature. A new feature of J-KEM’s controllers called ‘Ramp-To-Setpoint’

allows a specific rate for evacuation to be entered (e.g., reduce the pressure to 20 torr at a rate of 10

torr/Hour). A second feature called ‘Soak’ then lets you specify how long to stay at that pressure before

turning off.

Example of Program Ramps

Setpoint

Time

Ramp

Soak

Power Off

Pressure

Setpoint

Time

Ramp

Soak

Power Off

Pressure

The controller is shipped with the Ramp-to-Setpoint feature OFF, the user must specifically turn Ramp-to-

Setpoint ON. When Ramp-to-Setpoint is OFF, the controller evacuates to the entered setpoint at the

fastest rate possible (i.e., the rate that results from fully opening the vacuum valve). When Ramp-to-

Setpoint is ON, the controller evacuates at the user entered ramp rate.

The Ramp-to-Setpoint feature and its associated parameters are turned on and set in the controller’s

programming mode. The parameters of importance are:

SPrr

SetPoint Ramp Rate. Allowable Values: 0 to 9990 torr/Hr.

This specifies the desired evacuation rate. Note, this parameter specifies the desired rate of evacuation.

Extremely high evacuation rates will not be maintained if the rate exceeds the capacity of the vacuum

pump. To minimize fluctuations around the setpoint a needle valve may be needed between the Digital

Vacuum Regulator and the vacuum pump.

SPrn

SetPoint Ramp Run. Allowable Values: ON, OFF, Hold

This parameter turns the ramping feature ON or OFF. During an active run, if this parameter is set to

‘Hold’, the setpoint ramp stops and holds at its current value. This continues until the parameter is set to

ON or OFF. When set to OFF, the values in SetPoint Ramp Rate and Soak Time are ignored.

SoAK

Soak Time. Allowable Values: “- -”, 0 to 1440 min.

This specifies the amount of time to soak at the setpoint after the setpoint vacuum ramp is complete. A

setting of “- -” causes the controller to remain at the final setpoint indefinitely. A numeric value causes

the controller to stay at the setpoint for the entered time and then turn power off to the vacuum valve. The

pressure in the vessel will increase depending on the number of leaks in the system.