Accessories, Maintenance, Cleaning – Silverline Air Impact Wrench User Manual

Page 9: Storage, Disposal, Problem possible cause solution, Troubleshooting

8

GB

Accessories

• Accessories for this tool, including sockets and socket sets, are

available from your Silverline stockist. Spare parts can be obtained

from your Silverline dealer or www.toolsparesonline.com

Maintenance

WARNING: Always disconnect from the air supply and depressurise before

cleaning or carrying out any maintenance.

Cleaning

• Keep your tool clean at all times. Dirt and dust will cause internal parts

to wear quickly, and shorten the machine’s service life. Clean the body of

your machine with a soft brush, or dry cloth

IMPORTANT: There is very little that can go wrong with your air tool and it

should be noted that when an air tool fails to work it is generally because

the internal workings have corroded due to dirty, wet air and failure to

follow the instructions given below.

Daily maintenance procedure: Disconnect from the air supply, pour the

equivalent of a tablespoon of oil into the air intake. Connect tool to the air

supply and run motor briefly (e.g. 2-4 seconds) at low speed to distribute

the oil.

Once a week: Disconnect tool from the air supply. Remove the hex screw

to open the Oil Point (6) marked ‘OIL’ and pour in a few drops of air tool

oil. Replace the hex screw and tighten to seal the oil point. Connect tool

to the air supply and run motor briefly (e.g. 2-4 seconds) at low speed to

distribute the oil.

• If the machine is in constant use or used for long periods at a time, a

combined filter/lubricator must be fitted. There must be an air filter fitted

at all times

• Use air tool oil. DO NOT UNDER ANY CIRCUMSTANCES USE NORMAL

ENGINE OIL

• Failure to comply with the operating and maintenance instructions may

invalidate the guarantee

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

• As with other power tools, air tools should not be disposed of with

household waste

• Air tools may contain traces of tool oil and other lubricants and so must

be recycled accordingly

• Contact your local waste disposal authority for information on the correct

way to dispose of power tools

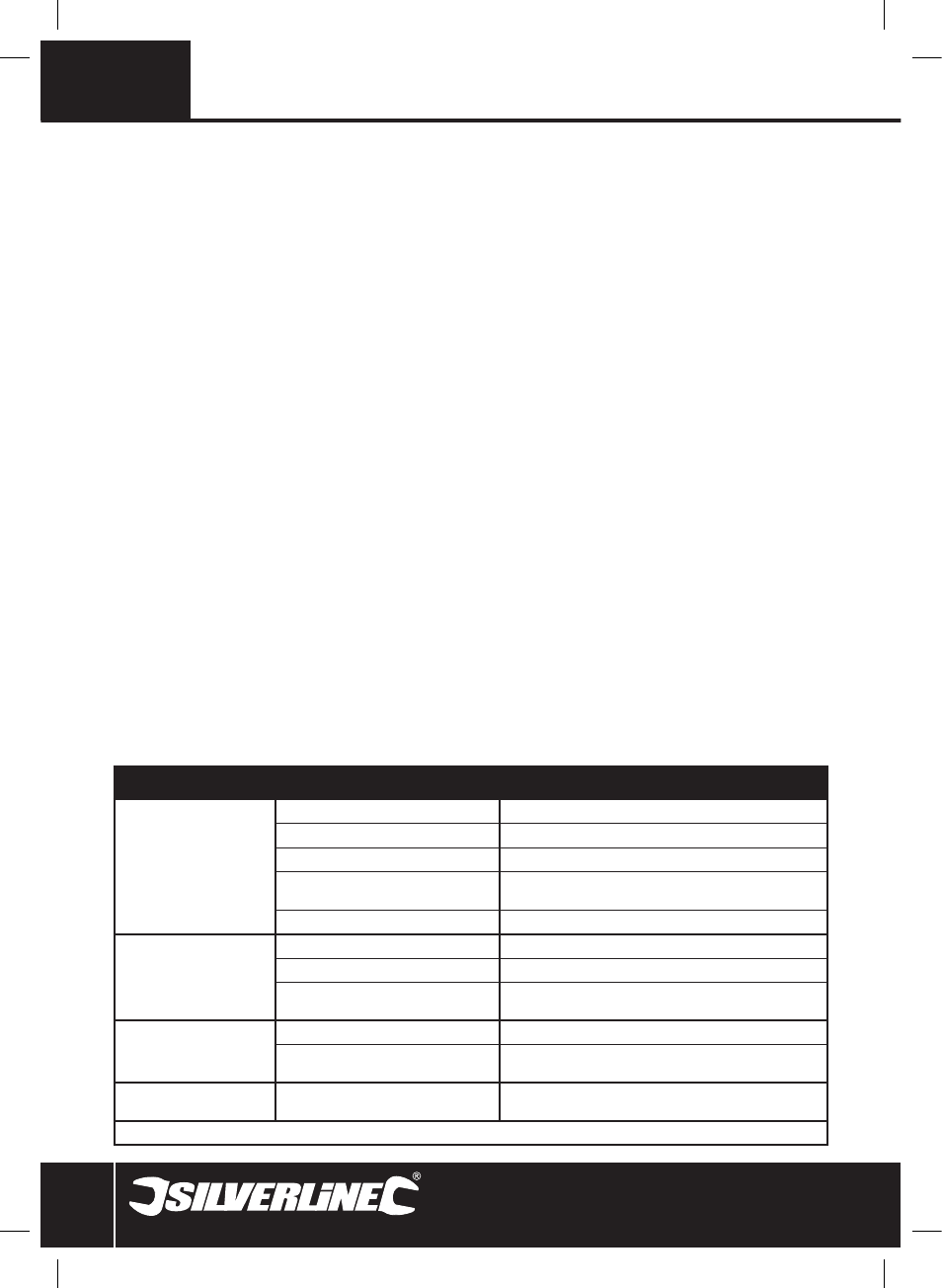

Problem

Possible Cause

Solution

Tool operating slowly

Pressure incorrect

Set the correct air pressure according to the specification

Dirt within the mechanism

Pour oil into air inlet as per maintenance instructions

Air blockage

Operate tool in short bursts to clear blockage

Air leak

Check all fittings and hose for air leaks and correct issue by re-

tightening, using PTFE tape or replacing

Blockage in gauze mesh filter

Remove quick connector and clean mesh filter

Tool seized

Dirt or rust in mechanism

Try ‘Tool operating slowly’ solutions

Dirt or rust in mechanism

Tap tool gently with a soft mallet

Dirt or rust in mechanism

Free mechanism by rotating drive manually when disconnected from

air line

Normal no load speed but tool

slows down under load

Worn motor or clutch parts

Contact an authorised Silverline service centre

Motor or clutch sticking

Pour oil into air inlet as per maintenance instructions and operate tool in

short bursts to lubricate and free up

Tool will not stop after trigger is

fully released

Throttle valve O-ring or valve seat damaged

Have the tool repaired at an authorised Silverline service centre

If the above troubleshooting solutions fail, contact your dealer or an authorised Silverline service centre.

Troubleshooting

719770_Z1MANPRO1.indd 8

03/07/2013 18:11