Unpacking your tool, Before use, Operation – Silverline Air Impact Wrench User Manual

Page 8: Eq-4, En-6

www.silverlinetools.com

7

719770

Air Impact Wrench

Intended Use

• Air driven impact wrench, for use with standard ½" sockets to loosen

and tighten nuts and bolts.

Note: This device is not a torque wrench. Always torque nuts/bolts with a

calibrated torque wrench.

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all

its features and functions

• Ensure that all parts of the tool are present and in good condition. If

any parts are missing or damaged, have such parts replaced before

attempting to use this tool

Before Use

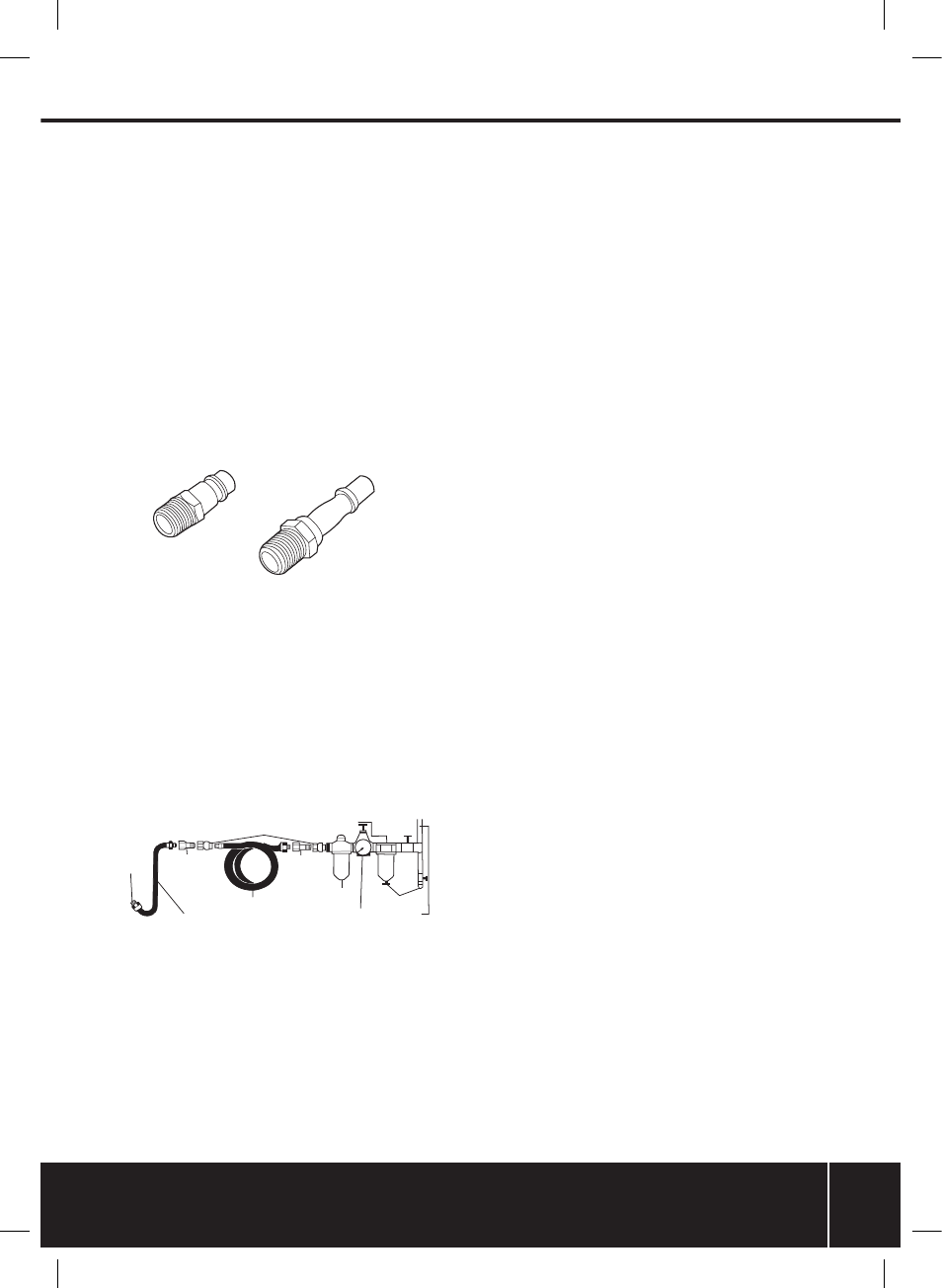

Fitting the quick connector

Note: This tool is supplied with two different male airline quick connectors:

EQ-4 – commonly used in Europe

EN-6 – mainly used in the UK

• Please choose the connector that is compatible with the airline system

you are using, and install as outlined below:

1. Apply some PTFE tape (not included) to the screw threads of the Quick

Connector (3). This will help to maintain an air-tight seal

Note: Apply PTFE tape tightly and in a clockwise direction, so it does not

come off when the thread is screwed into the tool.

2. Remove the protective plug from the air inlet

3. Using a spanner (not included) screw the quick connector into the air

inlet located at the base of the handle

4. Connect to airline, pressurise carefully and carry out a leak check (e.g.

by spraying small amounts of soapy water on to the outside of the

connectors)

• Air lines fitted with matching female quick connectors will now be a push

fit to the tool

Air supply connection

• This tool should be connected to a clean, dry air supply with inline oiler

and water separator

• Do not allow supply pressure to exceed the maximum stated (see

“Specifications”)

• Ensure that water is drained from air system daily

• Ensure that all parts of the system (hoses, couplers, etc.) are correctly

rated for the air pressure to be used

Setting tool power

• The tool speed can be adjusted by pressing and turning the Air/Torque

Control Dial (4):

‘1’ = minimum, ‘4’ = maximum

Forward and reverse

This tool features a forward/reverse function. Select the desired direction by

pushing the Forward/Reverse Switch (2). The letters ‘F’ and ‘R’ marked on

the tool indicate the switch position for forward and reverse:

• Bar exposed above trigger = ‘F’ – forward (clockwise rotation)

• Bar exposed at rear of tool = ‘R’ – reverse (anticlockwise rotation)

Note: The terms ‘forward’ and ‘reverse’ refer to right hand threads.

Installing a socket

WARNING: Always disconnect the tool from the air supply before attaching

or removing sockets.

1. Push a suitable socket firmly over to locking ring on to the 1/2” Square

Drive (1)

2. Ensure the locking ring engages and the socket is firmly attached by

trying to pull it off the drive

Note: Firmly pull the socket off the drive to remove.

Operation

Loosening a nut or bolt

1. Place the socket over the nut

2. Hold the tool firmly by the handle. Your thumb should wrap around the

handle and your fingers should sit on the Trigger (5)

3. Brace the machine with your other hand on the back of the tool to

control torque reaction

4. Press the Forward/Reverse Switch (2) inwards until it protrudes out

the back of the housing

5. Press the trigger to start the tool

6. When the nut or bolt starts moving, release the trigger to stop the tool

and remove the socket from the nut or bolt. Remove the nut from the

socket if needed

Note: DO NOT allow the ratchet to run in ‘idle rotation’ for an extended

period of time. This will shorten its life.

WARNING: If the tool cannot loosen the nut, DO NOT raise the outlet

pressure of the air compressor. Use a manual spanner instead to loosen

the nut or bolt.

Tightening a nut or bolt

1. Check the torque setting and ensure the nut or bolt can withstand the

torque selected

2. Tighten the nut or bolt as far as possible by hand

3. Place the socket over the nut

4. Hold the tool firmly by the handle. Your thumb should wrap around the

handle and your fingers should sit on the Trigger (5)

5. Brace the machine with your other hand on the back of the tool to

control torque reaction

6. Press the Forward/Reverse Switch (2) inwards until it protrudes out

the front of the housing

7. Press the trigger to start the tool

8. When the nut has been tightened, remove the tool and socket

WARNING: DO NOT over-tighten. You should use a calibrated torque wrench

to torque the nut to the correct value after using the impact wrench.

WARNING: NEVER increase the air pressure above the maximum operating

pressure stated in ‘Specifications’ if the tool stalls wile tightening or the

torque produced is insufficient.

WARNING: Be aware that air tools may hold residual pressure after use.

Always bleed air pressure from the tool after shutting off air supply.

EQ-4

Europe

EN-6

UK

TO YOUR

AIR TOOL

LEADER HOSE

NIPPLE

QUICK COUPLER

WATER SEPARATION

OILER

NIPPLE

REGULATOR

DRAIN DAILY

AIR SUPPLY

RECOIL HOSE

719770_Z1MANPRO1.indd 7

03/07/2013 18:11