Intended use, Unpacking your tool, Before use – Silverline Air Grease Gun 400cc User Manual

Page 7: Eq-4, En-6

6

GB

Filling with grease

WARNING: Avoid spillages! Clean up spilled grease immediately and DO NOT allow

grease to enter the environment. Spilled grease may cause surfaces to become

slippery, causing a slipping hazard.

Note: Before using this tool, the user should consider the implications of using

grease cartridges. Over time, the use of cartridges will cause the seal of the

plunger mechanism to wear, affecting the gun’s performance so that it will not seal

when being filled with grease directly.

1. Ensure the grease gun is disconnected from the air supply before you begin

2. Unscrew the Chamber (7) from the body of the Grease Gun (2)

Installing a cartridge

1. Pull the Plunger Handle (5) back so that it is fully extended

2. Remove any packaging from the cartridge

3. Insert the cartridge fully into the chamber, as directed on the cartridge

4. Screw the chamber securely back onto the gun

5. Press the Plunger Release (6) to release the plunger mechanism

Filling from a container

1. Pull the Plunger Handle (5) back so that it is fully extended

2. Use a spatula to pack the grease directly into the chamber, taking care not to

accidentally press the Plunger Release (6)

3. Once filled, clean any excess from the edge of the chamber

4. Screw the chamber securely back onto the gun

5. Press the plunger release to release the plunger mechanism

Loading from a filler pump

Note: This is general guidance for a filler pump. Read the instructions provided

with your filler pump in combination with these when filling.

1. Pull the Plunger Handle (5) back so that it is fully extended

2. Hold the grease gun vertically so the Filler Pump Nozzle (10) is at the top and

the plunger release can’t be accidentally operated

3. Insert the filler plug on the end of the hose from the filler pump into the filler

pump nozzle

4. Operate the filler pump pumping mechanism to load the grease

5. Stop pumping when the required grease is loaded or if there is noticeable

resistance to loading

6. Disconnect the filler plug from the filler pump nozzle and wipe the nozzle

7. Press the Plunger Release (6) to release the plunger mechanism

Note: When only partially loading the chamber, carefully control the spring plunger

mechanism so that when the plunger release is pressed, you continue to hold the

plunger handle in order to control the descent of the plunger mechanism.

Bleeding the grease chamber

• After filling, remove any pockets of air trapped in the chamber:

1. Disconnect from the air supply

2. Check that the plunger is released. If not, depress the ratchet release

3. Unscrew the Chamber (7) from the body of the Grease Gun (2) 1 to 1-1/2

turns

4. Draw back the Plunger Handle (5) fully

5. Push plunger handle all the way in again

6. Retighten the chamber

7. Depress the Bleed Valve (11) several times to let the air escape

Attaching a spout

1. Ensure the Grease Nipple (1) is clean

2. Connect the required spout by screwing the threaded end into the grease

nipple

3. To remove a spout, unscrew it from the grease nipple

TO YOUR

AIR TOOL

LEADER HOSE

NIPPLE

QUICK COUPLER

WATER SEPARATION

OILER

NIPPLE

REGULATOR

DRAIN DAILY

AIR SUPPLY

RECOIL HOSE

Intended Use

• Grease dispensing gun, powered by compressed air from a compressor,

suitable for bulk and cartridge grease, ideal for lubricating vehicles, agricultural

machines and industrial equipment.

Unpacking Your Tool

Carefully unpack and inspect your tool. Familiarise yourself with all its features

and functions.

Ensure that all parts of the tool are present and in good condition. If any parts are

missing or damaged, have such parts replaced before attempting to use this tool.

Before Use

Fitting the quick connector

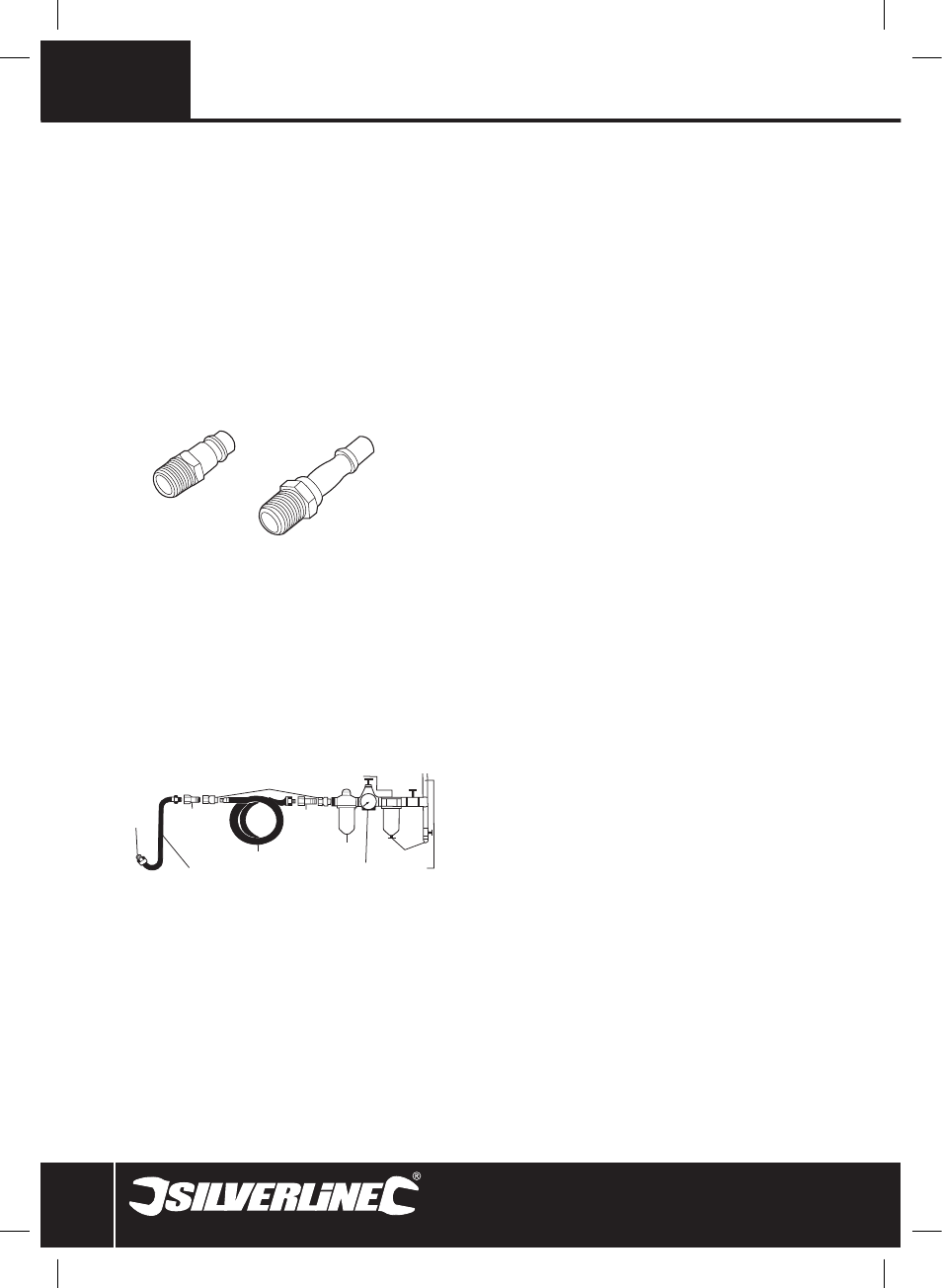

Note: This tool is supplied with two different male airline quick connectors:

EQ-4 – commonly used in Europe

EN-6 – mainly used in the UK

• Please choose the connector that is compatible with the airline system you are

using, and install as outlined below:

1. Apply some PTFE tape (not included) to the screw threads of the Quick

Connector (4). This will help to maintain an air-tight seal

Note: Apply PTFE tape tightly and in a clockwise direction, so it does not come off

when the thread is screwed into the tool.

2. Remove the protective plug from the air inlet

3. Using a spanner (not included) screw the quick connector into the air inlet

located at the base of the handle

4. Connect to airline, pressurise carefully and carry out a leak check (e.g. by

spraying small amounts of soapy water on to the outside of the connectors)

• Air lines fitted with matching female quick connectors will now be a push fit

to the tool

Air supply connection

• This tool should be connected to a clean, dry air supply with inline oiler and

water separator

• Do not allow supply pressure to exceed the maximum stated (see

‘Specifications’)

• Ensure that water is drained from air system daily

• Ensure that all parts of the system (hoses, couplers, etc.) are correctly rated for

the air pressure to be used

Setting tool power

• The speed/pressure with which grease is expelled can be adjusted by reducing/

increasing the air supply pressure within the range specified in ‘Specifications’

EQ-4

Europe

EN-6

UK

427558_Z1MANPRO1.indd 6

07/11/2013 12:27