Edgecraft Chef's Choice 130 User Manual

Page 8

underStandIng the profeSSIonal Steeled edge

With the Chef’sChoice

®

Professional Sharpening Station

®

you will for the first time be able to

experience the pleasure of cutting and slicing with perfectly steeled edges. You can in just sec-

onds create steeled edges with that extra “bite” and sharpness unmatched by even the most

experienced professionals.

The steeling Stage 2 contains a unique miniature steel made of a special high carbon steel

hardened to about Rockwell C-65 which is much harder than any commercially available cut-

lery. Consequently this special rod will show very little wear from repeated contact with the edge

as you steel your finest and hardest knives.

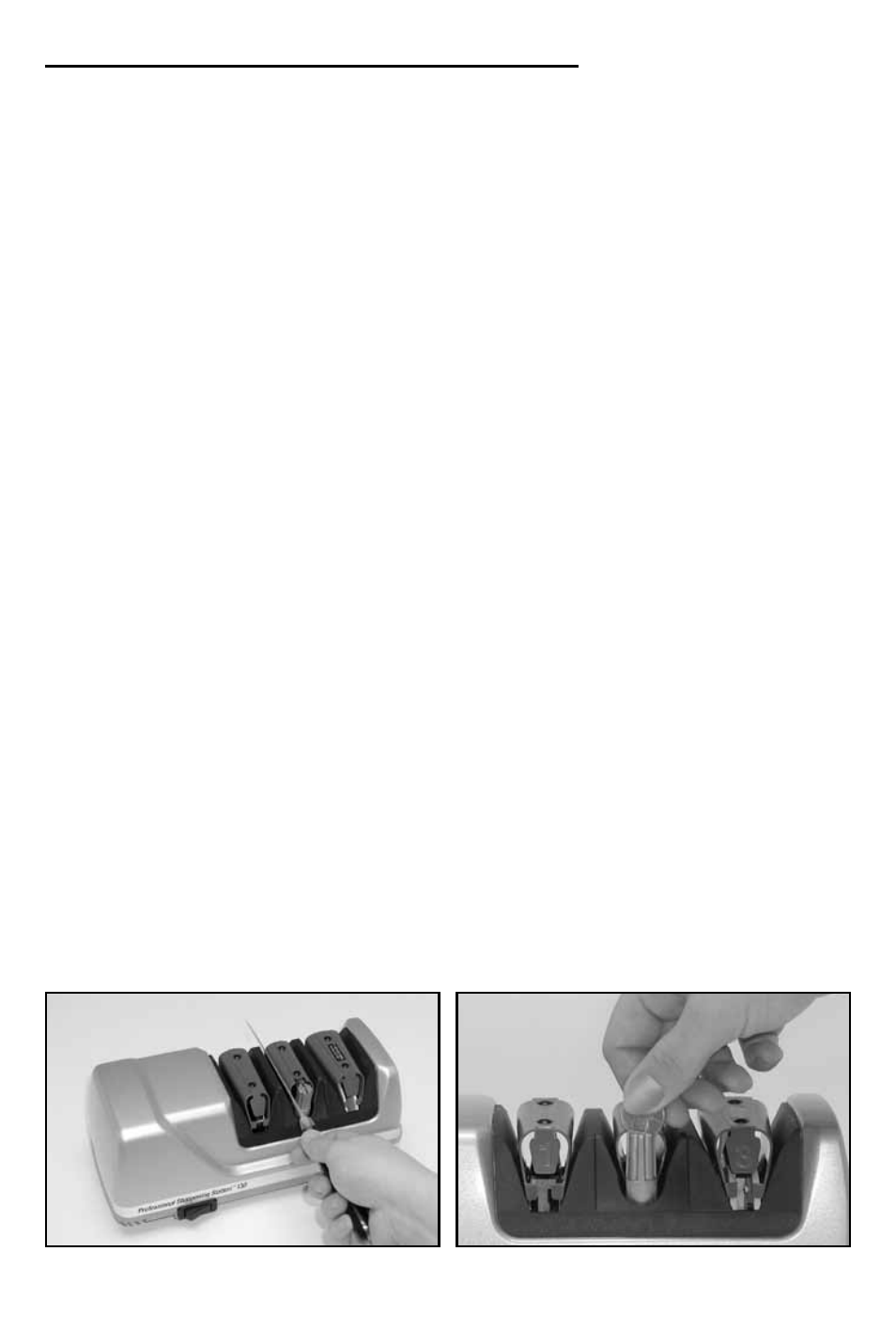

Precision knife guides in Stage 2 control and precisely align the face of the knife as the blade

is inserted into the slot between the guide and the blade retention spring (See figure 8). To use,

insert the blade alternately into the left and then the right slots and pull forward so that the knife

is held securely and the edge slides along the surface of the hardened miniature steel. When

steeling, it is not necessary to turn on the electrical power, however power is always needed

when using Stages 1 and 3.

The steel rod is supported by elastomeric materials that allow the rod to deflect when ex-

cessive force is applied to the blade. This feature and the ultra-precise and consistent angular

contact maintained stroke after stroke between the knife edge and the hardened steel rods are

key to optimizing the edge structure. Viewed under a microscope, the edge created by steeling

in Stage 2 presents a uniform formation of exceedingly fine and super-sharp micro-serrations.

Even after many uses and steeling of the knife edge, the original edge geometry is maintained

and the edge does not round-off like it would using a conventional manual steel, which has no

angle control.

Because of the consistent and precise angular control, Stage 2 maintains a shaving sharp

edge while it creates the uniform row of microscopic serrations along the knife edge. If the edge

is damaged when used for cutting, the Steeling Station will restore the edge micro-serrations

while maintaining the sharpness of the edge. This type of edge conditioning is unique to the

Sharpening Station.

At the top of the miniature steel rod is a slotted cap that accepts a coin or other tool so you

can rotate the steel rod slightly (one “click”) to expose a fresh area of the steel rod surface

(Figure 9). This is necessary only if the rod becomes sufficiently worn locally that the edge

conditioning process slows significantly. When the rod is rotated, fresh surfaces of the steel

are made available in both the left and right slots. A spring finger extends from the end of the

knife retention spring and clicks into a shallow groove in the cap on top of the steel rod. When a

Figure 8. Blade should be Steeled alternately in left and

right slots of Stage 2.

Figure 9. Rotating the steel with coin in slot.

8