Raft, Andling – Glastender Remote Beer Dispensing System User Manual

Page 6

Glastender, Inc. • 5400 North Michigan Road • Saginaw, MI • 48604-9780

800.748.0423 • 989.752.4275 • Fax 989.752.4444 • www.glastender.com

3

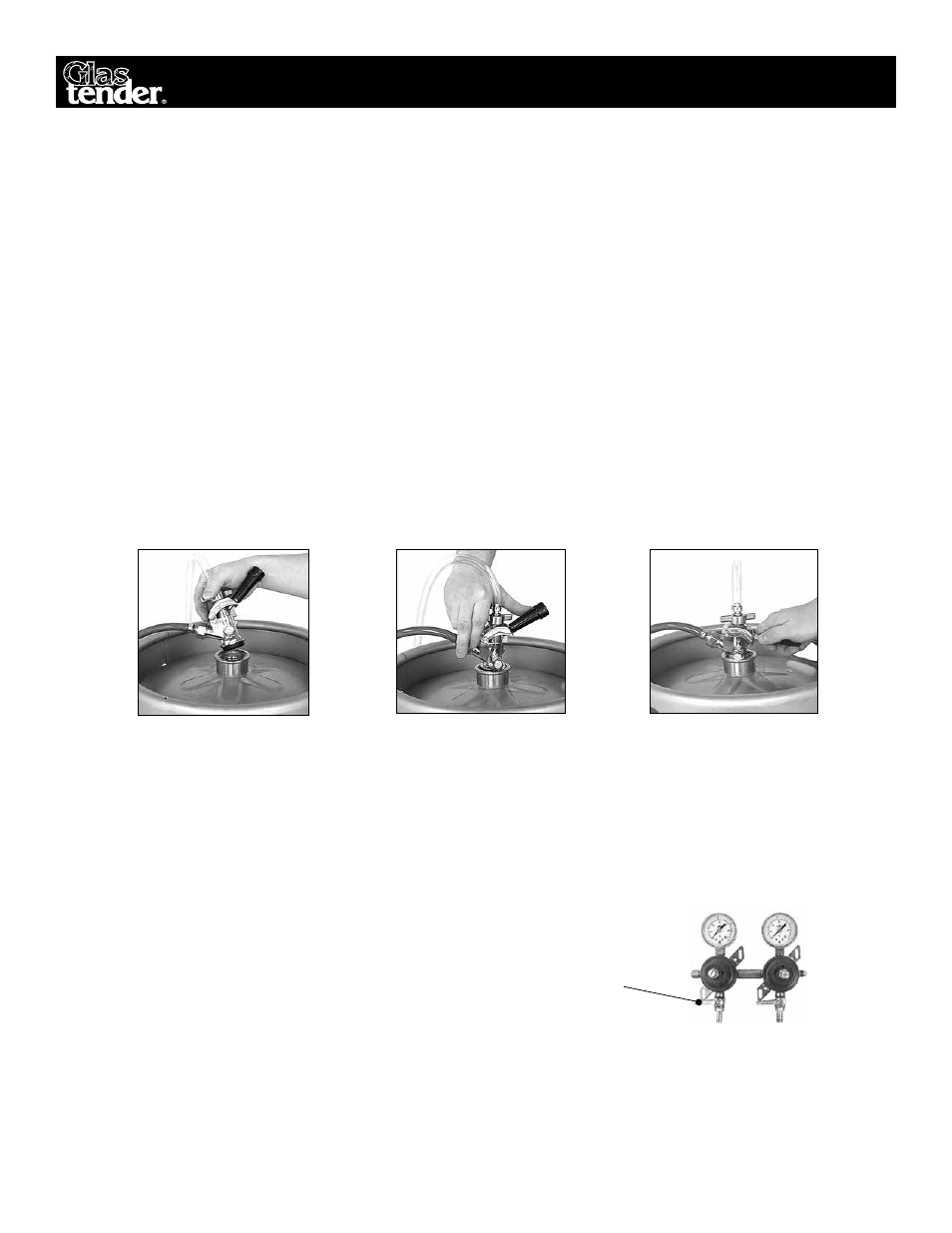

Placing the Keg Tap on the Barrel

Glastender normally provides a lever-type keg tap for each keg in the beer system. Please refer to the following instruc-

tions when placing a keg tap on the barrel.

Position the tap head in

the barrel neck.

Turn the handle clock-

wise a ¼ turn.

Pull the handle out and

push it down to the

locked position, which

activates the pressure

and beer lines. You are

now ready to draw beer.

d

raft

B

eer

H

andlIng

NOTE: When removing a keg tap, first turn off the sec-

ondary regulator to the tap, located by following

the red air line from the keg tap to the secondary

regulator shut-off valve. Pictured to the right is

a sample two product secondary regulator with

shut-off valves in the closed or off position.

Shut-off valve

System Operation

A properly balanced system should provide at least some head (foam) on a glass of beer. A normal head can be up to one

inch thick. While most bartenders tend to pour off the foam until there is virtually no head, at least some foam should be

expected. Proper pouring techniques will help minimize excess foaming. It is also important to remember that frosty mugs

cause the beer to foam more than normal, so this should be considered when system performance is being evaluated.

Once a beer system is operating, there are really no adjustments that need to be made, unless a new brand of beer is intro-

duced. In fact, adjusting the pressure regulators haphazardly creates more problems than it solves. Fluctuations in walk-in

cooler or keg temperature are often the cause of temporary foaming problems. In these instances, adjusting the regulators

will not help and will likely create problems later on when the temperature problem goes away. The best way to ensure

proper system operation is to follow the regular maintenance schedule outlined in the operation manual.