Troubleshooting – Goulds Pumps 4550 - IOM User Manual

Page 29

TROUBLESHOOTING

1.

Priming - Liquid level in sump not equal to or greater

than minimum submergence.

2.

Speed too low - check whether motor wiring is

correct and receives full voltage.

3.

System discharge head too high - check system head,

particularly friction losses.

4.

Suction lift too high - check sump level.

5.

Impeller or piping obstructed - check for

obstructions.

6.

Wrong direction of rotation - check rotation.

7.

Air pocket in casing increasing - increase level in

sump.

8.

Float controls operating incorrectly - check

operation.

9.

Entrained air or gases in liquid - consult factory.

10. Impeller clearance too great - check for proper

clearance.

11. Impeller damaged - inspect and replace as required.

12. Rotating parts bind - check internal wearing parts for

proper clearances.

13. Shaft bent - straighten or replace as required.

14. Coupling or pump and driver misaligned - check

alignment and realign if required.

15. Impeller diameter too small - consult factory for

proper impeller diameter.

16. Improper pressure gauge location - check correct

position and discharge nozzle or pipe.

17. Pump cover O-ring damaged - check O-ring and

replace as required.

18. Speed too high - check motor winding voltage.

19. Head lower than rating; pumps too much liquid

-consult factory. Install throttle valve, cut impeller.

20. Liquid heavier than anticipated - check specific

gravity and viscosity.

21. Cavitation - Consult factory. Increase NPSH

available.

22. Bearings worn out - inspect and replace as required.

Assure bearings have proper lubrication.

4550 IOM 5/08

25

6

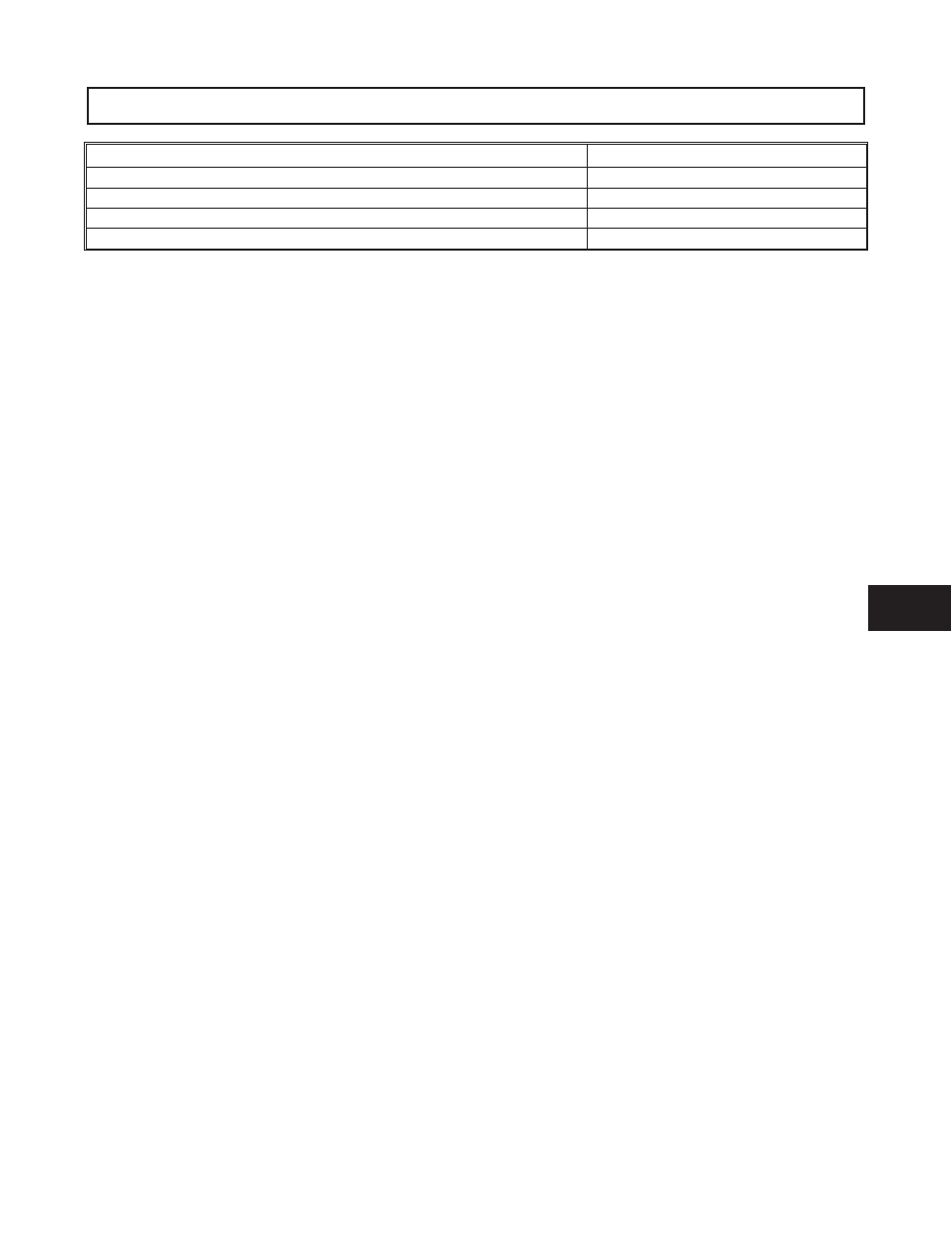

Problem

Possible Causes & Corrections

No liquid delivered, not enough liquid delivered or not enough pressure

1, 2, 3, 4, 5, 6, 7, 9, 10, 11, 15, 16, 17

Pump works a while and then quits

4, 5, 7, 8, 9, 17

Pump takes too much power

6, 10, 11, 12, 13, 14, 18, 19, 20, 22

Pump is noisy or vibrates

4, 12, 13, 14, 21, 22