Barksdale Series 20415 User Manual

Page 10

Barksdale, Inc. 3211 Fruitland Avenue, Los Angeles CA 90058 (800)835-1060 www.barksdale.com Bulletin No. 272367-B, 4-3-14

10

Disassembly

1. Disconnect all fittings from the regulator and pilot motor

2. Turn locking device(27) counterclockwise first. Turn handle(29) counterclockwise to remove load from

compression springs

3. Remove spring housing bolts(22)

4. Lift the spring housing assembly(16) together with spring(20, 21) and SPRING gland(17)

5. Remove

flanges

a. Remove bolts(22) from inlet/vent(36) and blind(47) flanges, pull the flanges out

b. Remove bolts(22) from bottom(43) flange, pull out flange

c. Note: If using major repair kit, remove bolts (37) from inlet/vent flange (36) and blank flange (47). Remove

inlet plate (34) and blocking plate (46).

6. Remove piston gland(14) and push out the slide assembly(2, 12) towards the top, Remove piston(12) and

slide assembly(2)

7. Take out pressure seals(6, 7) from slide(2)

8. Uninstall all soft goods (o-rings and back-up rings)

Cleaning and Inspection

1. Thoroughly clean and inspect the slide(2) and piston assembly(2, 12). Look for signs of wear, replace if

necessary

2. Thoroughly clean and inspect the wear plates on the internal side of the inlet/vent(36) and outlet(40) flanges.

Look for signs of wear or scratching, replace if necessary.

3. Inspect all pressure seals(6, 7) for wear, if signs of damage, replace.

4. Check all o-rings, back-up rings and washers, replace if necessary.

Re-assembly

1. Lightly lube all soft goods from Repair Kit with petroleum based lube (mobile lube)

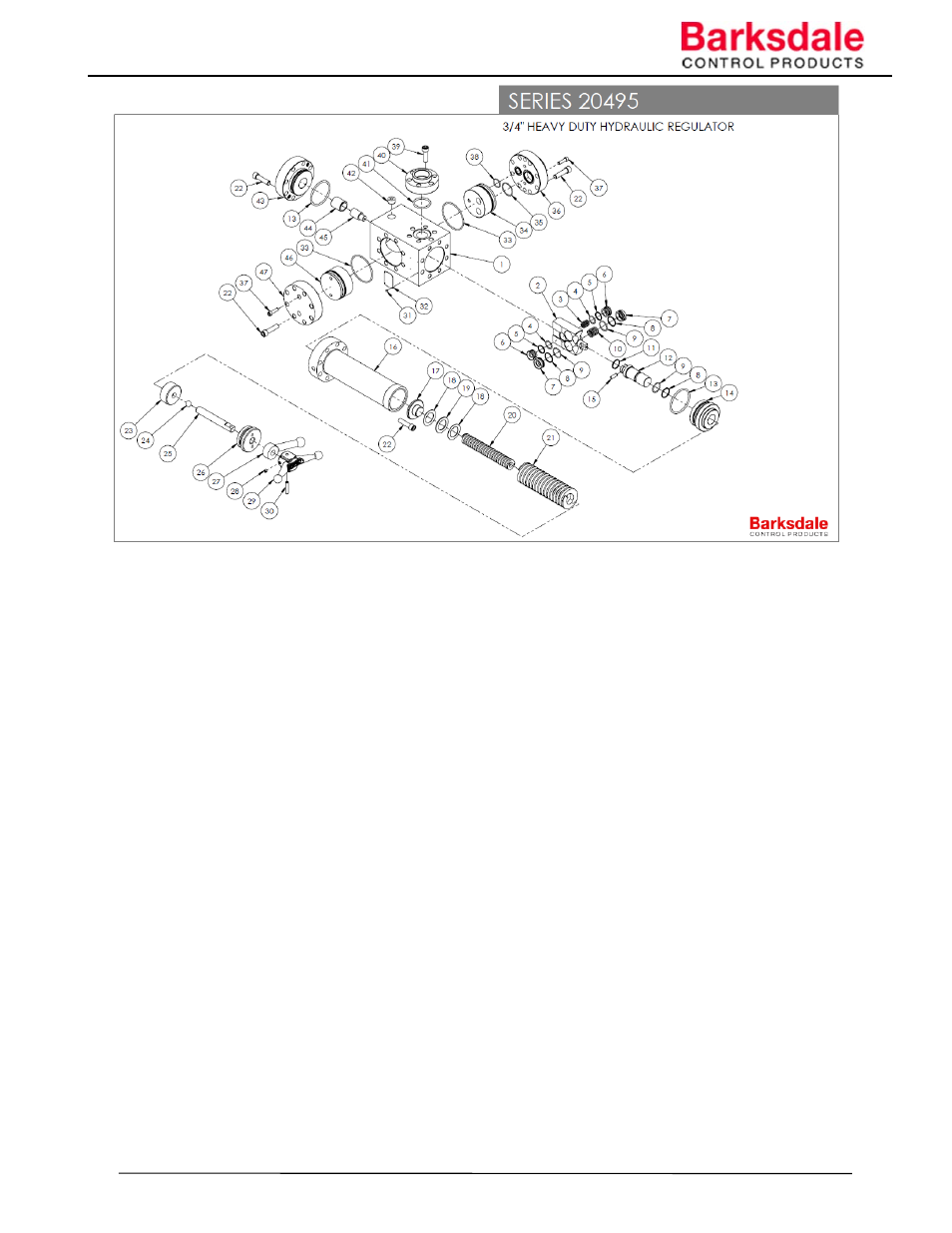

2. Re-install all o-rings (wherever back-up rings are used, refer to exploded view drawing to assure proper

orientation of back-up rings in relation to o-rings)

3. If using major repair kit, ensure o-rings (35,38) are installed prior to aligning inlet plate (34) to inlet flange

(36) and secure with bolts (37), torque to 140-180 in-lbs. Repeat steps for blocking plate (46) and blank

flange (ensure proper alignment); install bolts (37) and torque to 140-180 in-lbs.

4. Re-install pressure seals(6, 7) and springs(3, 10) back into the slide(2) (make sure back-up o-rings are not

extruding)