Myron L 597 User Manual

Page 3

PLEASE READ THIS THROUGH COMPLETELY BEFORE

ATTEMPTING TO INSTALL OR OPERATE THIS SYSTEM.

DESCRIPTION

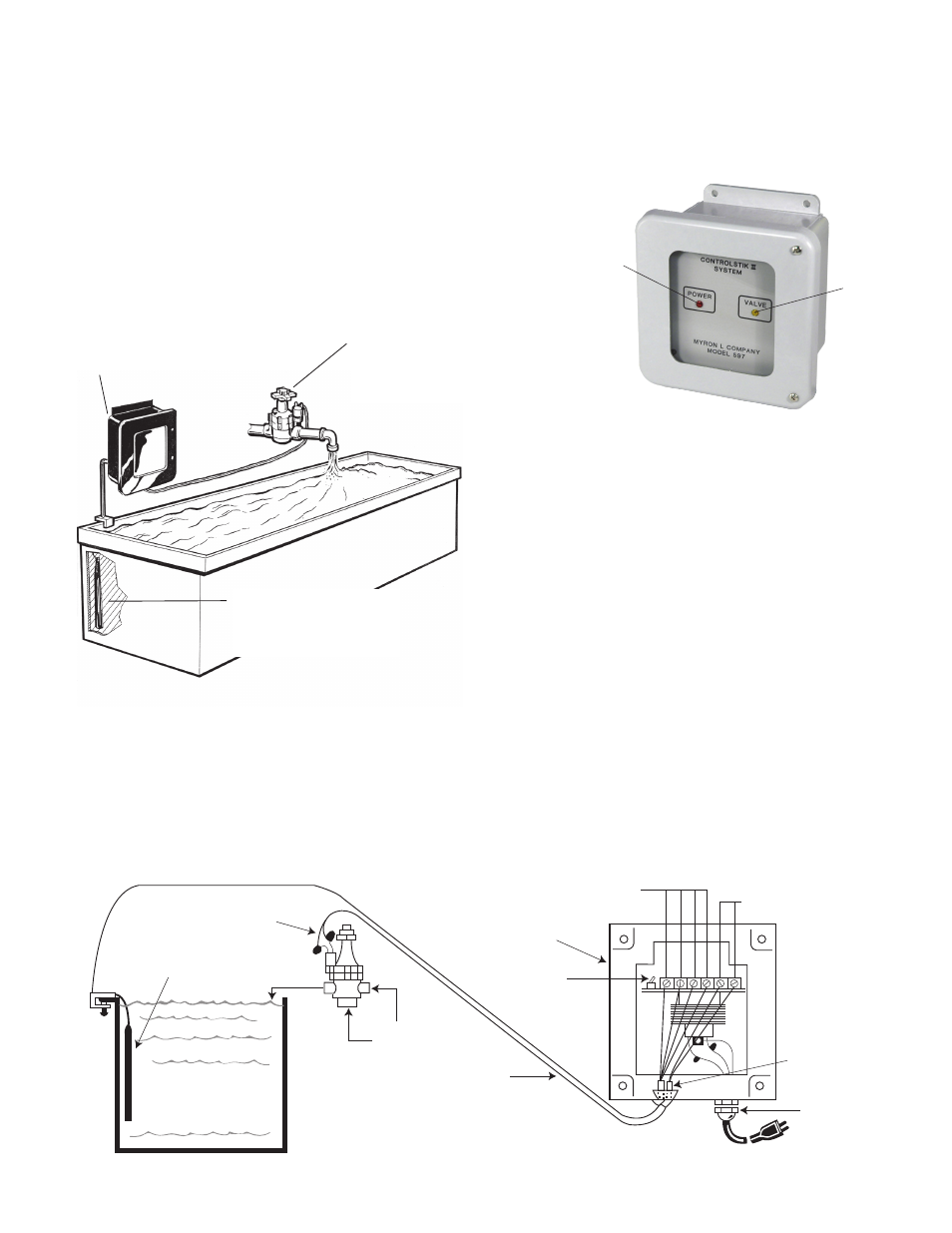

The Myron L Controlstik Rinse Tank System is a fully automatic

control which will greatly reduce the amount of water used in

continuous flow rinse tanks. At the same time, it automatically

maintains water quality, insuring effective rinsing in water up to

82°C (180°F). It operates on the electrical conductivity principle

and is fully stable and protected against all environmental

conditions including temperature, line voltage, water

contamination and corrosion.

Controlstik Rinse Tank System has three major parts:

After installation, the Controlstik (sensor) is submerged in the

rinse water. When contamination (dragin) accumulates beyond

the point “safe” for good rinsing, the sensor automatically opens

the Solenoid Valve. Fresh water flows into the tank, and as

excessive contamination is diluted back to the “safe” level, the

sensor closes the valve, limiting water use.

INSTALLATION AND OPERATION PROCEDURES

A.

Mounting

Follow local electrical code

CAUTION: Do not apply power until all wiring has been

completed and connections checked.

1. Mount the Transformer Box near the correct AC power as

indicated on your unit. It may be hung on a wall, panel, or

post.

2. Hang Controlstik (sensor) in the tank by the cord, using the

securing clamp to hold the cord onto the edge of the tank.

The sensor should hang vertically, fully submerged at least

10 cm (4 in.) off the tank bottom and not closer than 60 cm

(2 ft.) to the inlet water line. If tank is small, locate sensor at

end opposite from inlet.

NOTE: If water rate is slow or if dragin rate and concentration

prevent good diffusion of contamination … the following

should be considered to insure the Controlstik senses

water that is “representative” of the entire tank:

1. Agitation - by air or other means

2. Installation of weir in tank perpendicular to water flow

3. Use of spider (sparge) on inlet

B. Piping

1. Install valve in inlet water line to rinse tank so that flow

direction is as indicated by the arrows on the top of

valve body.

2. Use Teflon tape on all connections and plug the unused inlet.

3. Insure flow control is at least partially open by turning

counterclockwise.

1. TRANSFORMER BOX

Reduces line power to safe

level for sensor and solenoid valve.

3. CONTROLSTIK SENSOR

Adjustable set-point minimizes

tampering. Two ranges built-in for

tap and purified water.

2. SOLENOID VALVE

1”, corrosion-resistant

with flow control and

manual override.

24V For safety.

2. Solenoid Valve

Water Inlet

(Options)

1. Transformer Box

Controlstik

Valve

Cap Plug

Strain Relief

Range Switch

105-125 VAC, 50/60 Hz (no cord/plug

supplied with 210-250 VAC 50/60 Hz model)

Low Voltage Wire

(not supplied)

3. Controlstik (Sensor)

completely immersed

CAUTION: Maximum

operating temperature

is 82ºC (180ºF)

R

ed

G

re

en

B

lac

k

W

hit

e

POWER

Light

1. TRANSFORMER BOX

VALVE

Light

1